Learn more

Browse Products

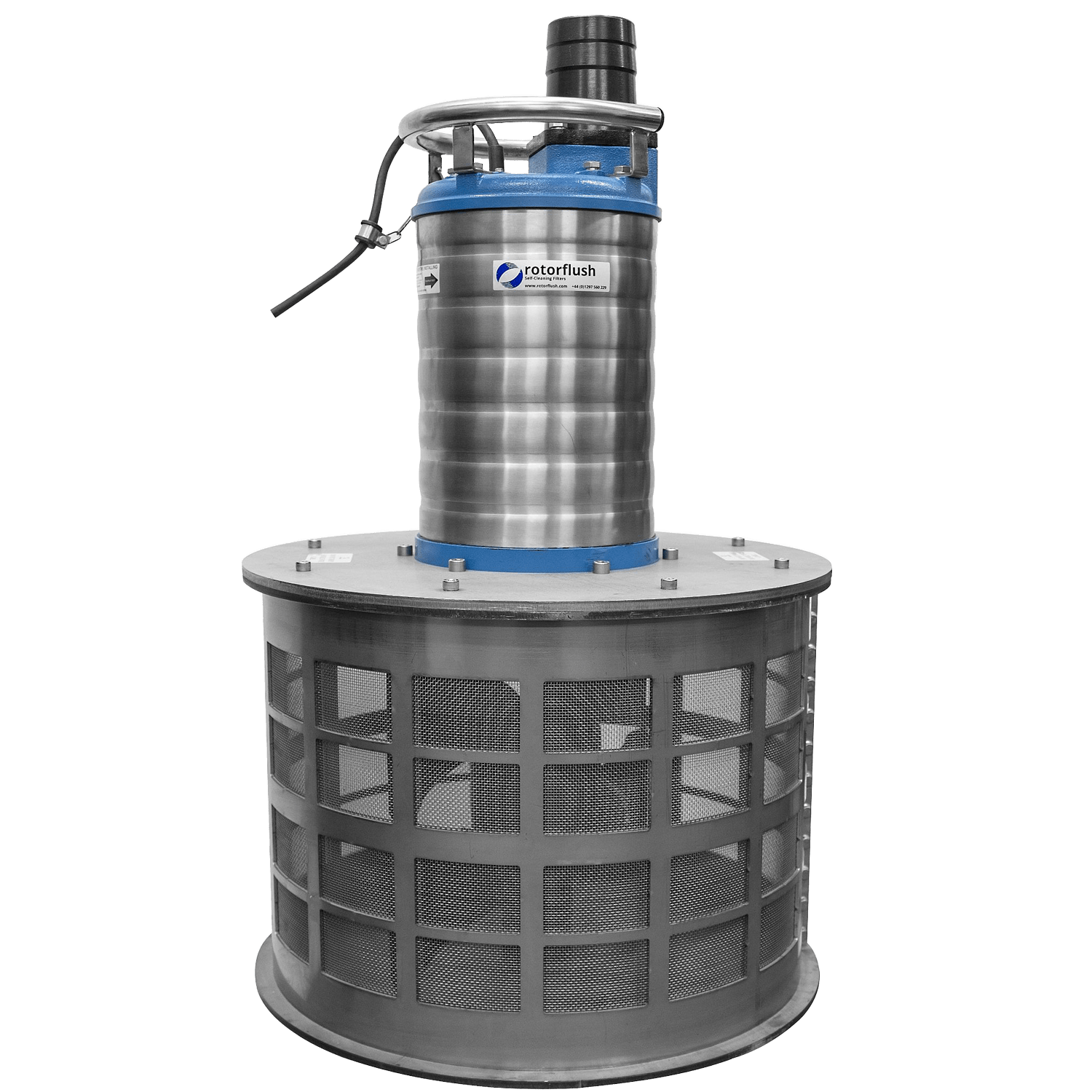

RF800LW Self-cleaning Strainers and Eel Screens

Self-cleaning Industrial Water Strainers and Eel Screens. Our RF800LW industrial strength, low maintenance, stainless steel self-cleaning basket strainers protect equipment from blocking and blinding when pumping dirty water. These suction side screens handle up to 1085m3/hour, 4,775 US GPM.

- Screen up to 1085 m3 / hour, 4775 US GPM

- Filter from 6 mm down to 1 mm

- US Mesh 3 down to 18

- Ideal for Fish and Eel Screening

Price from: £10,980

Sapphire 400 Filterpumps™

Rotorflush Sapphire Filterpumps™ are general purpose high pressure submersible filter pumps with a built-in self-cleaning suction intake screen. Pump and screen up to 50 m3/h, 220 US GPM, and to a maximum head of 20 bar, 290 psi.

- Maximum output - 50 m3/h, 220 US GPM

- Maximum head - 200 m, 656 ft

Price from: £8,985

Opal 600 Filterpumps™

Industrial Submersible Water Pumps with a Built-in Self-cleaning Suction Intake Screen used for pumping dirty or contaminated water. Opal 600 Filterpumps™ are extremely tough filter pumps, suitable for heavy industrial applications. They will pump and screen up to 3,166 litres a minute, 836 US GPM, and have a maximum head of 23.2 bar, 335 psi.

- Maximum output -190 m3 / hr

- Maximum head - 232 m

Price from: £0

Cobalt 600 Filterpumps™

Industrial Submersible Water Pumps with a Built-in Self-cleaning Suction Intake Screen. These Rotorflush Cobalt 600 filter pumps are low to medium pressure, robust filter pumps offering high volume pumping and screening - up to 108 m3 / hr, 475 US GPM.

- Maximum Output - 108 m3 / hr, 475 US GPM

- Maximum Head - 30 m, 98 ft

Price from: £16,090

Sapphire 600 Filterpumps™

Industrial Submersible Water Pumps with a Built-in Self-cleaning Suction Intake Screen. Rotorflush Sapphire Filterpumps™ are general purpose high pressure submersible filter pumps with a built-in self-cleaning suction intake screen. Pump and screen up to 90 m3/hr, 400 US GPM, and to a maximum head of 14 bar, 200 psi.

- Maximum output - 90 m3/hr, 400 US GPM

- Maximum head - 140 m, 460 ft

Price from: £19,020

Filterpumps™ for Sampling

Self-cleaning filter pump. The O1608-16 sample pump is a low head submersible filter pump with an integral self-cleaning filter for use with on-line analysers and dosing systems. It delivers a filtered output of water which prevents blockage to nozzles, valves and solenoids. Sample water can be screened to 60 microns and pumped simultaneously.

- Maximum output - 220 l / min, 58 US GPM

- Maximum head - 11 m, 36 ft

Price from: £1,970

Water Treatment Filtration

The UK Water Industry makes extensive use of Rotorflush self-cleaning filters and filter pumps. Our products are used for:

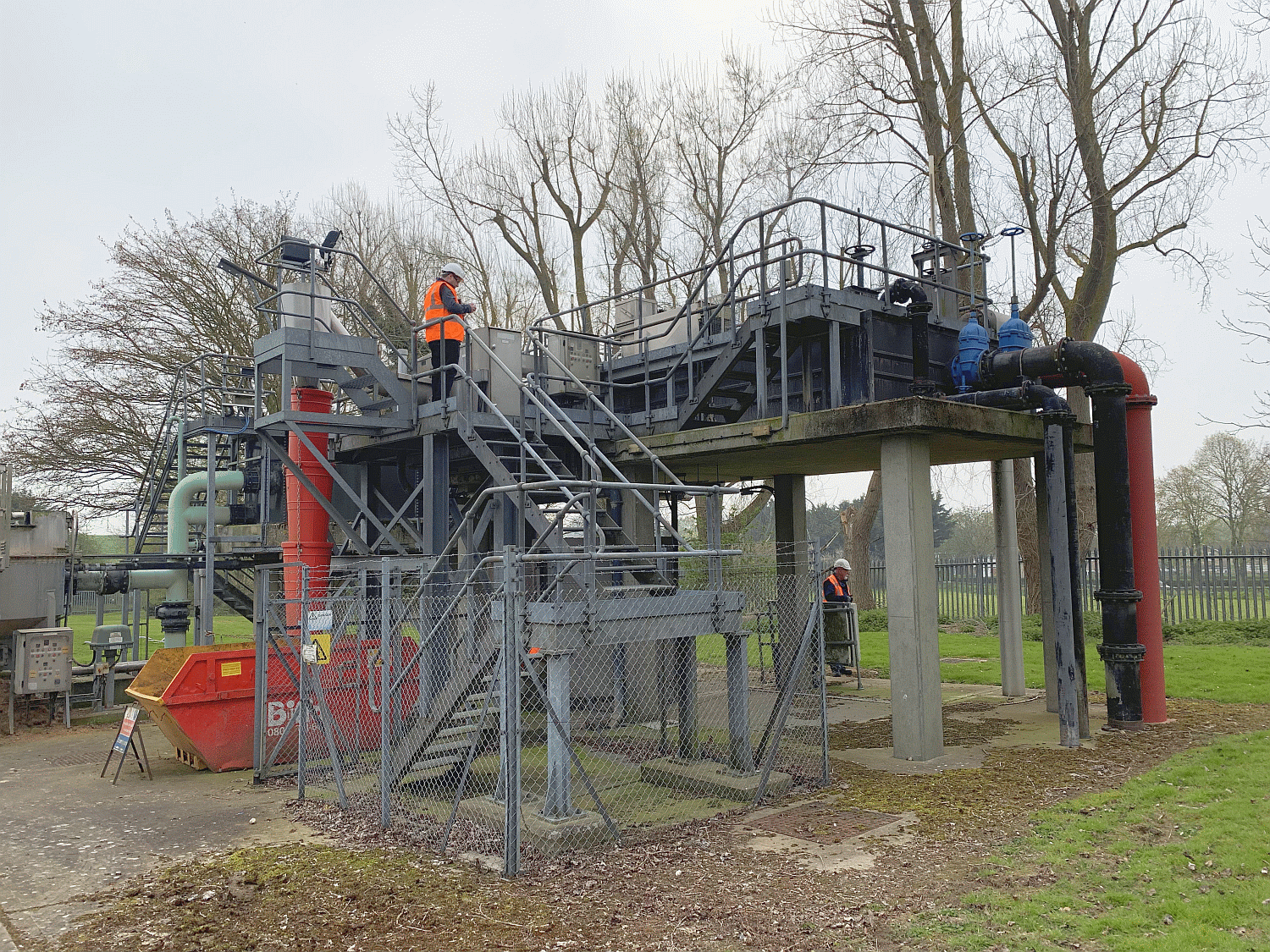

Wash Water at Sewage Treatment Works

Intake screens frequently block and clog. Trash and intake screens are cleared using high pressure wash water. As the source of this water is on the dirty side of the STW, a pump that will screen and pump final effluent without blocking is essential for low maintenance running of these plants. And that's what Rotorflush Filterpumps™ do. The filtered water they pump keeps spray bars and nozzles from clogging with suspended solids, weed or debris.

Water Sampling and Analysis

There is a constant need in the water industry to monitor water quality at all stages of water treatment. Our smaller filter pumps and Analyser Filter Systems protect analytical equipment at water monitoring sites. They provide protection to equipment to help ensure continuous monitoring and are very low maintenance.

Other water and utility companies internationally are also discovering the cost and maintenance benefits of our products. We provide innovative, low maintenance, robust and reliable filtration for raw water, secondary and final effluent, and we are developing products for effective filtration in raw sewage.

Screening at Raw Water Intakes

Screening at Raw Water Intakes

Environmental legislation for the protection of eels and fish now applies to many uses of raw water. Rotorflush's self-cleaning intakes on all our products allow 2 mm screening of raw water while keeping the screen mesh clear. As well as meeting regulatory requirements, these very low maintenance screens have the added benefit of reducing the load of particulate and debris further down the line.

Rotorflush submersible filter pumps with their integral self-cleaning filters can pump up to 2,500 liters per minute and filter to 60 microns.

Rotorflush Filterpumps™ for Wash Water at Treatment Works

Rotorflush submersible filter pumps offer a range of capabilities and installation options for providing waste water treatment wash water. Because of this versatility, many waste water treatment projects have integrated our products into their designs.

All Rotorflush self-cleaning filters and submersible pumps filter directly from the water source. Therefore, pumps with self-cleaning intakes can be suspended in secondary and final effluent. Pumping and filtering are combined, and the filters self-clean as the pumps operate.

The filter mesh stays clear, pumps and other equipment – spray bars, nozzles and pipework – do not block. The filters stay clear without the need for expensive built-in in-line filtration or compressed air driven backwashes.

In many cases, installing self-cleaning filters directly in the water source can make considerable capital savings.

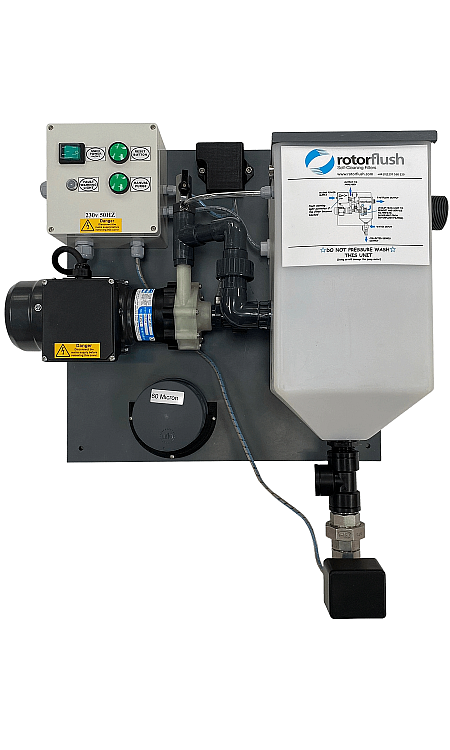

Self-Cleaning Analyser Filters for Online Analysers and Dosing Pumps

Over 200 RF100AN-Q Analyser Filter Systems have been supplied to the water industry as low maintenance filtration for online analysers. It is specifically designed to provide filtered samples for analysers and dosing pump systems with almost no maintenance.

It is excellent for filtering difficult samples contaminated with suspended solid for supply to chlorine, ammonia and other analysers.

Case Study

Trility were able to wash down the screen and were able to install and remove the screen easily when needed. They were impressed with the performance of the unit as a cost-effective alternative to inline screening or other filtering processes.

C J Hiscock, Sales

Rotorflush Filters LtdTrility, a water utility service provider operating in Australia, is a company that covers the full life cycle of water all the way through to waste water treatment. They approached us to trial a Rotorflush waste water treatment filter for the Redcliffe Sewage Treatment Plant in South East Queensland over a two-month period.

Trility concluded that the two-month trial was a success and that, in the absence of any access to screened wash water, the Rotorflush intake screen provided a viable alternative to in-line and other filtering options where these could not be used.

Read the Full Case StudyFrequently Asked Questions

Rotorflush self-cleaning filtration products are used for separating solids from dirty and contaminated water so that pumps, spray bars, irrigation and other equipment does not block or clog. Typical uses are:

- Screening and pumping wash water from final effluent

- Screening and pumping dairy run-off

- Screening and pumping filtered sample water to analysers

- Screening and pumping waste water at treatment works

- Eel screening at raw water intakes

All of our self-cleaning intake screens are specified to suit required flow rates.

Filter pumps are recommended based on the flow rate and pressure needed, taking into account any pressure losses through your set-up.

Intake strainers and screens are specified according to the maximum flow through that is required.

Consideration should be given to what mesh size you need - top tip, go for the largest mesh size you can get away with to minimise maintenance.

Yes, environmental regulations may determine the type of filter pump or strainer to be used. Products can be sized to account for Eel Regulations or EPA rule 316(b) if applicable, so that intake velocity and mesh size meet regulatory requirements.

We are an innovative and forward-looking company and are actively engaged in trials to enable effective screening of raw sewage. Watch this space. At the moment though, use of our products in raw sewage is not recommended.

The grease and oil in raw sewage combines readily with fibrous material and is extremely difficult to screen once it begins to accumulate. This is how fat bergs are formed. Screened sewage is better, and final effluent is OK.

Some people, however, have gained a benefit in very difficult water conditions by using our screens in combination with a rigorous maintenance regime - see this Case Study.

Yes – because our products pump and filter directly from a dirty water source, there is less need for expensive in-line filtration.

All our products have built-in self-cleaning back-washes that prevent intake screens from blocking, keep pumps clear and protect other connected equipment. This reduces maintenance, minimises downtime and can extend the life of pumps. Screening water for reuse can also cut costs.

Why Rotorflush?

UK Designed and Manufactured

Talk to our friendly team of engineers to discuss your design requirements.

- Built to your water output

- Filter down to 3 microns

- Hand built in the UK

Leading Water Filter Experts

Talk to our friendly team of engineers to discuss your design requirements.

- Industry experts for 30 years

- Supplied to over 200 industries, including waste water treatment

- Supplied worldwide

Worldwide Delivery and Service

Through our worldwide distribution network, we offer the ability to:

- Deliver filter pumps worldwide

- Help service your filter pump

- Repair broken filter pumps

Talk to an Expert About Your Project

Call us now on 01297 560 229 | 8am - 5pm GMT,

or Email sales@rotorflush.com and a member of our expert, friendly team will call you back and find the self-cleaning filter, strainer or filter pump to suit your needs.

- We work with you to identify your issues

- We can design & build a custom solution

- We can deliver our solution worldwide

Arrange a Call Back

Get the Filter Pump Your Project Requires. Talk to Our Friendly Team

This website uses cookies to ensure you get the best experience. Learn more