Learn More

How Rotorflush self-cleaning Screens Protect Eels and Fish

Rotorflush Filters Ltd have developed a range of our award-winning self-cleaning suction intake filters to comply with regulations for fish and eel screening. In Europe, most new and renewed abstraction licences require measures to be put in place for the Protection of European Eels, and screening for fish protection is becoming more prevalent in many countries.

These Regulations can apply to anyone drawing more than 20,000 litres a day - this impacts the water industry, farmers, cooling water, irrigators, and many industrial plants from paper mills to distilleries.

What Do Eel Screens Do?

Eel and fish screens protect young eels - glass eels and elvers - and fish fry from becoming entrained in waterworks, cooling systems, irrigation systems and other raw water intakes. They also prevent eels and fish from impingement on screens, enabling them to free themselves back into open water.

Entrainment means caught in the system, impingement means stuck on the intake screen.

Both possibilities are highly likely when you consider the huge volumes of water that are abstracted for industry, agriculture and human consumption each day, and that screening is required through 2 mm (or less) aperture mesh.

The purpose of Eel and Fish Screens is to constrain the velocity at which water flows through a mesh so that the flow is slow enough for small aquatic life to free itself; the mesh size of 2 mm or less is to ensure that young eels and fish cannot pass through.

Compliance by Design

The design of our self-cleaning filters and intake gives them a low intake velocity and a high open area, enabling compliance with current Eel regulations when pumping and abstracting raw water.

Rotorflush screens are designed for low intake speed through the screen mesh ; in addition, they are self-cleaning, so there is always a backwash from inside the screen to clear debris and wildlife off the mesh.

For any given flow rate being drawn or pumped, the intake velocity through the screen will decrease if the screen area is increased. Currently, the typical intake velocity of eel screens for the protection of glass eels and elvers is 0.1 metres / second, although this is likely to decrease as more stringent environmental regulations come into force.

As well as a low intake speed, the Eel regulations only allow a maximum screen aperture of 2 mm. 2 mm mesh can block very quickly, and this is a challenge for most equipment. Unlike most other self-cleaning filters and screens that only clean after the mesh has begun to block, Rotorflush intakes are designed to prevent blinding in the first place. They have a continuous self-cleaning backwash that keeps the mesh clear as water is drawn though the mesh.

Which Rotorflush Products Are Best for Eel Screening and Fish Protection?

Rotorflush Filters Limited Offer Two Product Sets for Eel and Fish Screening

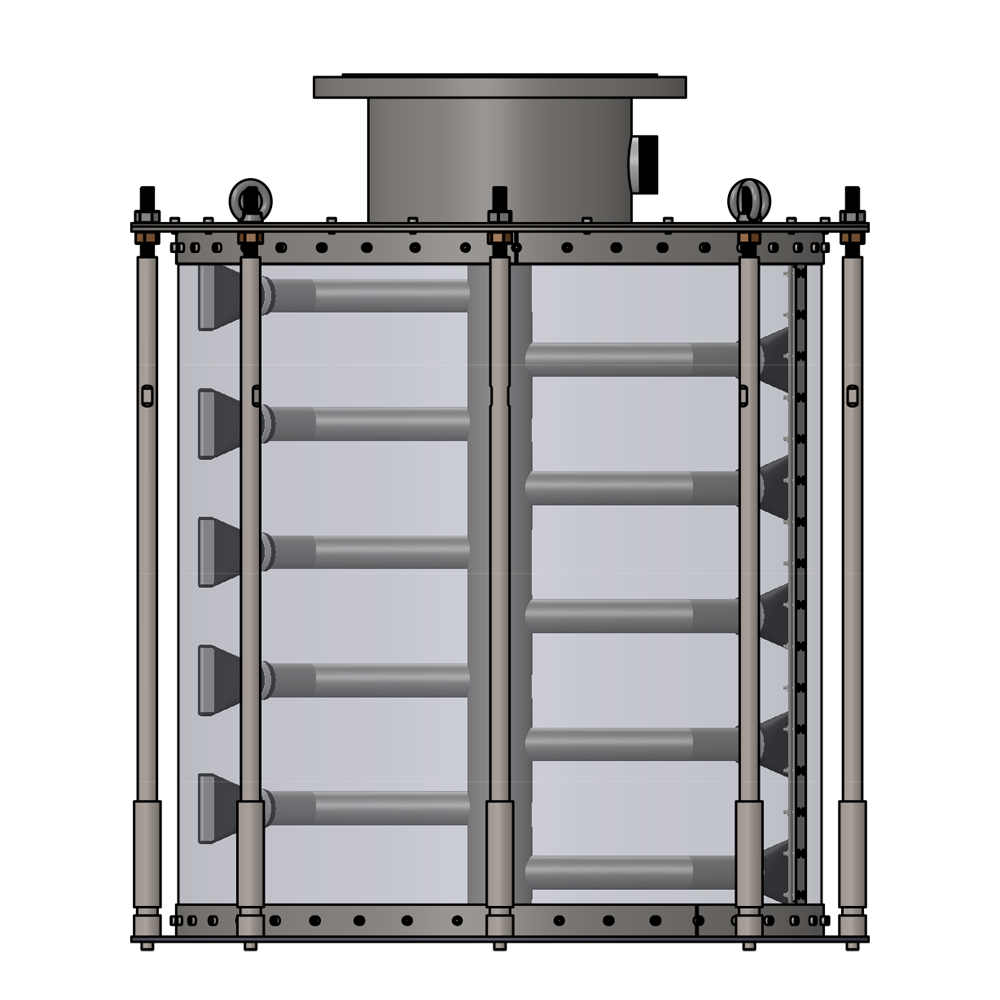

Self-cleaning Suction Intake Screens

Rotorflush Self-cleaning Eel Screens and Eel Screening Intake Strainers are designed for use on the suction hose of surface mounted pumps. They can also be used for gravity fed intakes, as long as a pump is used to supply the backwash.

The screens can be mounted vertically or horizontally and Rotorflush offer guide rail systems for lifting and maintenance.

These screens are typically used for large volume intake and comply with Eel regulations and EPA Rule 316(b). The 2 mm mesh and low intake velocity protects elvers and eels, and the self-cleaning mechanism ensures that the mesh stays clear.

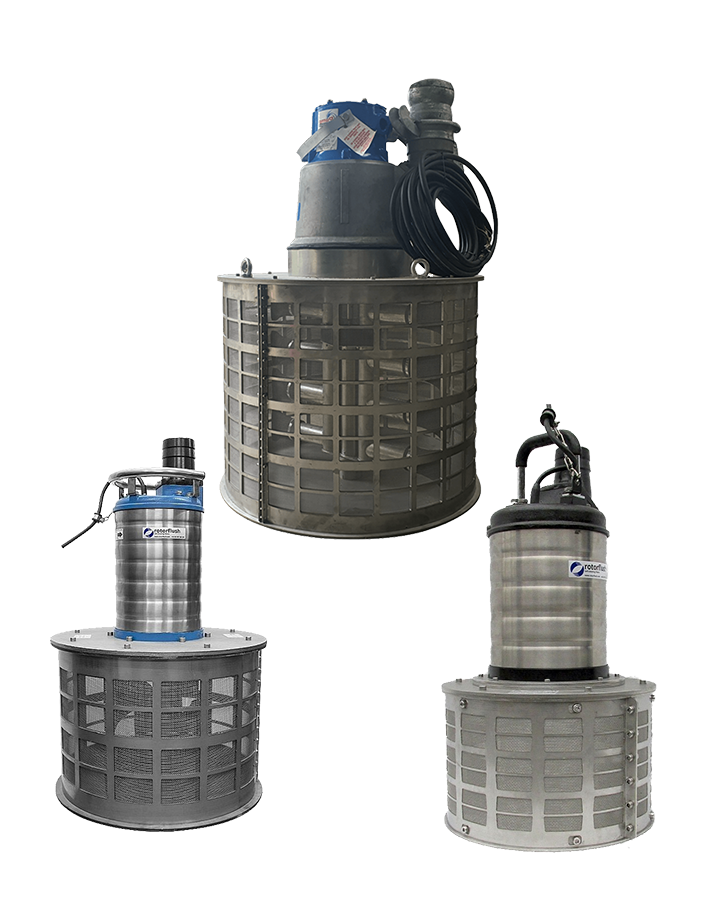

Submersible Pumps with Self-cleaning Suction Intakes

Rotorflush also manufacture and supply submersible Filterpumps™. These are submersible centrifugal multistage pumps with built-in self-cleaning intakes. This means they can be fitted with small intake screen mesh sizes and can comply with Eel regulations.

Screening and pumping are combined in the water source, eels and fish are screened, and the mesh stays clear because it continuously back washes as water is pumped.

Eel Screening Also Protects Equipment from Blocking

Our self-cleaning Eel Screening intake strainers and filter pumps have the added advantage that any downstream equipment – for example pumps, irrigators, wash water sprays, heat exchangers etc – also benefit from screened water, reducing the risk of blockage and clogging.

Designed for low intake velocities and with a high open mesh area, our eel screening products deliver high flow rates while taking up less space than fixed installations such as band screens or wedge wire screens.

Find out more about Rotorflush Eel Screens.

Browse Products

Pebble Filterpumps™

Rotorflush Pebble Filterpumps™. Pebble submersible filter pump with built-in self-cleaning filter on the pump suction intake. It has a maximum output of 80 L/min and a max head of 6m. They are our smallest filter pump, ideal for sampling, eel passes, small water features, and domestic use.

- Maximum Output 80 L/min

- Maximum Head 6 m

Price from: £910

Omnia Filterpumps™

Rotorflush Omnia Filterpumps™. Submersible pumps with built-in pump suction self-cleaning filters. Single phase low head filter pumps - up to 220 litres a minute, 45 US GPM. Ideal for sampling and small open loop heat pump systems.

- Maximum Output 220 L/ Min, 45 US GPM

- Maximum Head 11 m, 25 ft

Price from: £2,260

RF400 Self-cleaning Filters

RF400 Self-cleaning Filters. Self-cleaning Industrial Water Filters and Strainers. Extremely tough, stainless steel RF400 self-cleaning basket filters are for use on the pump suction hose of surface mounted pumps. The RF400 can filter up to 1000 litres per minute, 265 US GPM, from 50 microns to 6 mm.

- Screen Up to 1000 L/Min, 265 US GPM

- Filter From 6 mm Down to 50 Microns

- US Mesh 3 Down to 230

Price from: £4,070

Cobalt 400 Filterpumps™

Rotorflush Cobalt 400 Filter Pumps. Industrial low to medium pressure submersible pumps with an integral self-cleaning filter on the suction intake. These robust filter pumps offer high volume pumping and screening - up to 75 m3 / hr, 330 US GPM.

- Maximum Output - 60 m3 / hr, 265 US GPM

- Maximum Head - 19 m, 62 ft

Price from: £8,980

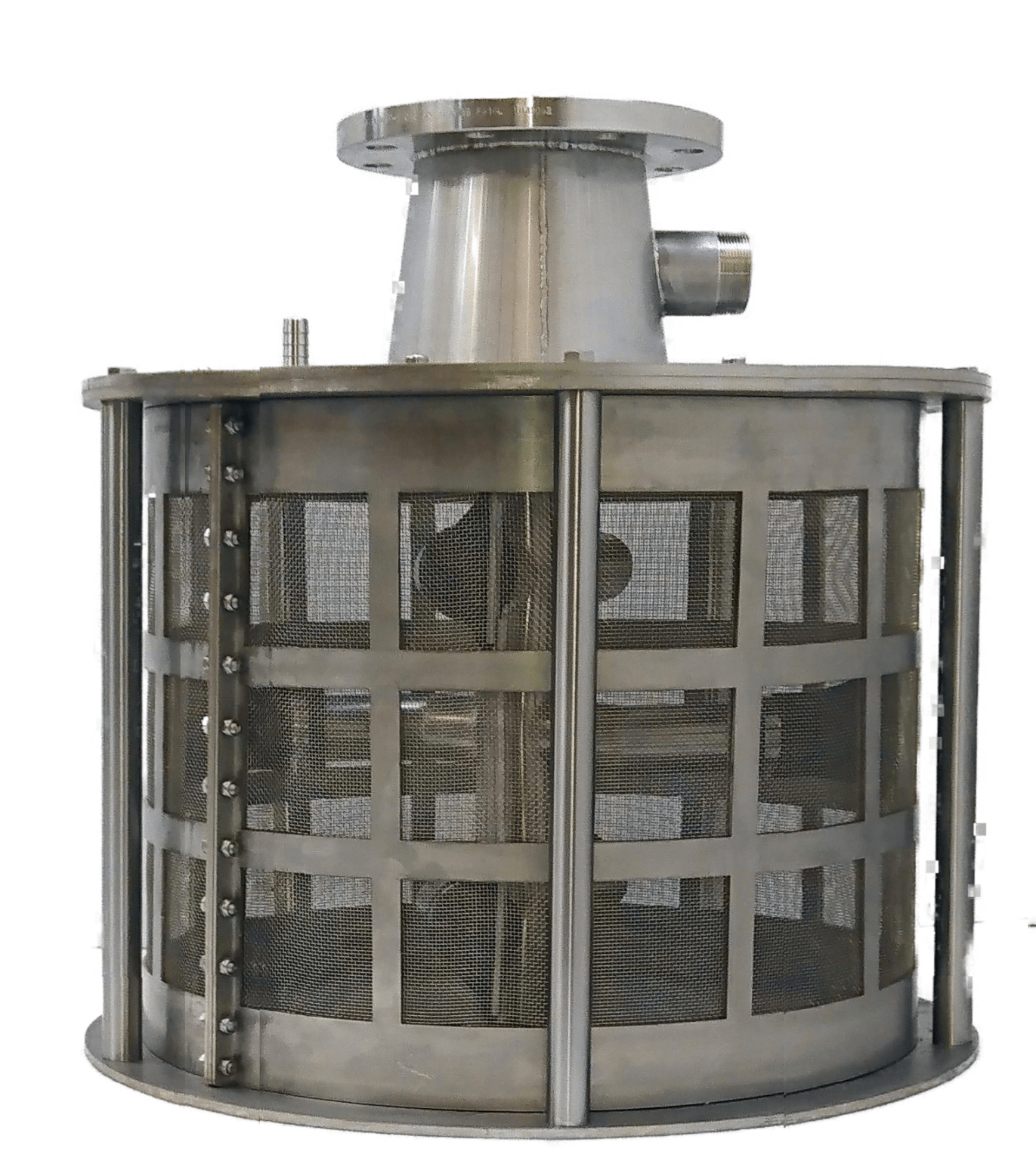

RF800AR Self-cleaning Strainer

RF800AR Self-cleaning Industrial Filters and Strainers. Our RF800AR self-cleaning intake strainers are for attachment to the suction hose of surface mounted pumps. These tough, industrial, all stainless-steel construction mechanical filters can deliver up to 870 m3/hour, 3830 US GPM

- Screen up to 870 m3 / hr, 3830 US GPM

- Filter from 6 mm down to 1 mm

- US Mesh equivalent 3 down to 18

Price from: £0

RF600LW Self-cleaning Filters

Self-cleaning Industrial Water Filters and Strainers. The RF600LWs are robust stainless steel self-cleaning basket filters that protect pumps and other equipment from blocking and blinding when pumping dirty water. They are fitted with 1 mm - 6 mm stainless steel mesh screens, handling up to 730 m3/hour, 3,215 US GPM.

- Screen Up to 730 m3 / hr, 3215 US GPM

- Filter From 6 mm Down to 1 mm

Price from: £9,845

RF1000AR Self-cleaning Strainer

RF1000AR Self-cleaning Industrial Water Filters and Strainers. 1000 mm diameter self-cleaning intake strainers for attachment to the suction hose of surface mounted pumps. These tough industrial all stainless-steel construction mechanical filters can deliver up to 1,045 m3/hour, 4,600 US GPM

- Screen up to 1045 m3 / hr, 4600 US GPM

- Filter from 6 mm down to 1 mm

- US Mesh equivalent 3 down to 18

Price from: £0

RF800LW Self-cleaning Strainers and Eel Screens

Self-cleaning Industrial Water Strainers and Eel Screens. Our RF800LW industrial strength, low maintenance, stainless steel self-cleaning basket strainers protect equipment from blocking and blinding when pumping dirty water. These suction side screens handle up to 1085m3/hour, 4,775 US GPM.

- Screen up to 1085 m3 / hr, 4775 US GPM

- Filter from 6 mm down to 1 mm

- US Mesh 3 down to 18

- Ideal for Fish and Eel Screening

Price from: £10,980

RF1000LW Self-cleaning Intake Strainers and Eel Screens

Self-cleaning Industrial Water Filters & Strainers. RF1000LW Suction Intake Strainers and Eel Screens, 1000 mm in diameter, for use in raw and contaminated water. Industrial strength, low maintenance, all stainless steel self-cleaning basket strainers to prevent blocking and blinding during water abstraction. These intake screens handle up to 1,357 m3 / hour, 5,975 US GPM (when fitted with 2 mm mesh).

- Screen up to 1357 m3 / hr, 5975 US GPM

- Filter from 6 mm down to 1 mm

- US Mesh 3 down to 18

- Ideal for Raw Water Intakes

Price from: £0

Talk to an Expert About Your Project

Call us now on 01297 560 229

or Email sales@rotorflush.com

and a member of our expert, friendly team will call you back and find the self-cleaning filter, strainer or filter pump to suit your needs.

- We work with you to identify your issues

- We can design & build a custom solution

- We can deliver our solution worldwide

Use this form to get in touch or send us Feedback about your Rotorflush experience

or Email feedback@rotorflush.com

Rotorflush Workshop on the leafy Dorset Devon border.