Learn More

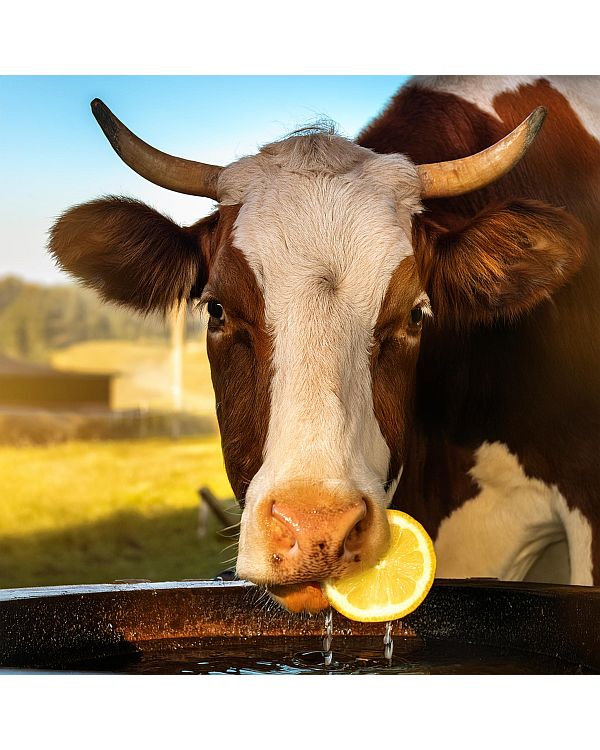

Livestock Watering

Raising livestock requires a lot of water. Sourcing water for livestock watering can mean abstracting raw water from streams, ponds or other natural water sources. Mains water is expensive, so making the best use of raw water, rainwater and recycling water where possible reduces costs.

Cattle watering and sheep watering are becoming more and more complex as herds get bigger and new farming methods are adopted. Animals need access to fresh drinking water - and a surprisingly lot of it - see the table below.

How Much Water Do You Need?

| Cattle | Water (litres/day) | |

| Cow with calf | 50 | |

| Dairy cow in milk | 68 - 155 | |

| Yearling | 24 -36 | |

| 2 year old | 36 - 50 | |

| Pigs | Water (litres/day) | |

| Lactating sow | 18 - 23 | |

| Gestating sow / boar | 13 - 18 | |

| Fattening pig | 3 - 10 | |

| Weaner | 1 - 3 | |

| Sheep | Water (litres/day) | |

| Ewe with lamb | 9 - 10.5 | |

| Pregnant ewe / ram | 4 - 6.5 |

Remote Livestock Watering Systems

There are growing concerns about both the environmental harm and the effect on animal health where there are no alternatives to livestock using natural surface water sources. Grazing animals near available natural water sources is not always feasible, and there are increasing concerns that this may sometimes cause problems. Increasingly, as herd sizes grow and modern animal husbandry becomes more mechanized, simply allowing animals access to available surface water is often no longer sufficient.

An excellent article about these issues - "Remote Pasture Water Systems for Livestock" by the Alberta Agriculture and Food and Agriculture Stewardship Division begins:

"In the past, livestock were turned out to summer pasture and allowed to walk through and drink from any slough, creek, river, or lake available to them. In the winter, livestock either ate snow, or holes were cut in the ice of these natural water sources for them to drink from. When these natural water sources were not available, dugouts were constructed. Today, allowing livestock direct access to surface water sources is a concern to livestock producers and to other water users. The practice is also a problem for livestock. Livestock producers want to provide a safe, reliable supply of good quality water for their livestock, and they want to increase their management to better utilize their pastures for livestock production. Many producers are using remote water systems and applying the latest technology available for extended livestock grazing and winter feeding of livestock away from the farmyard."

Read the rest of this article at thecattlesite.com.

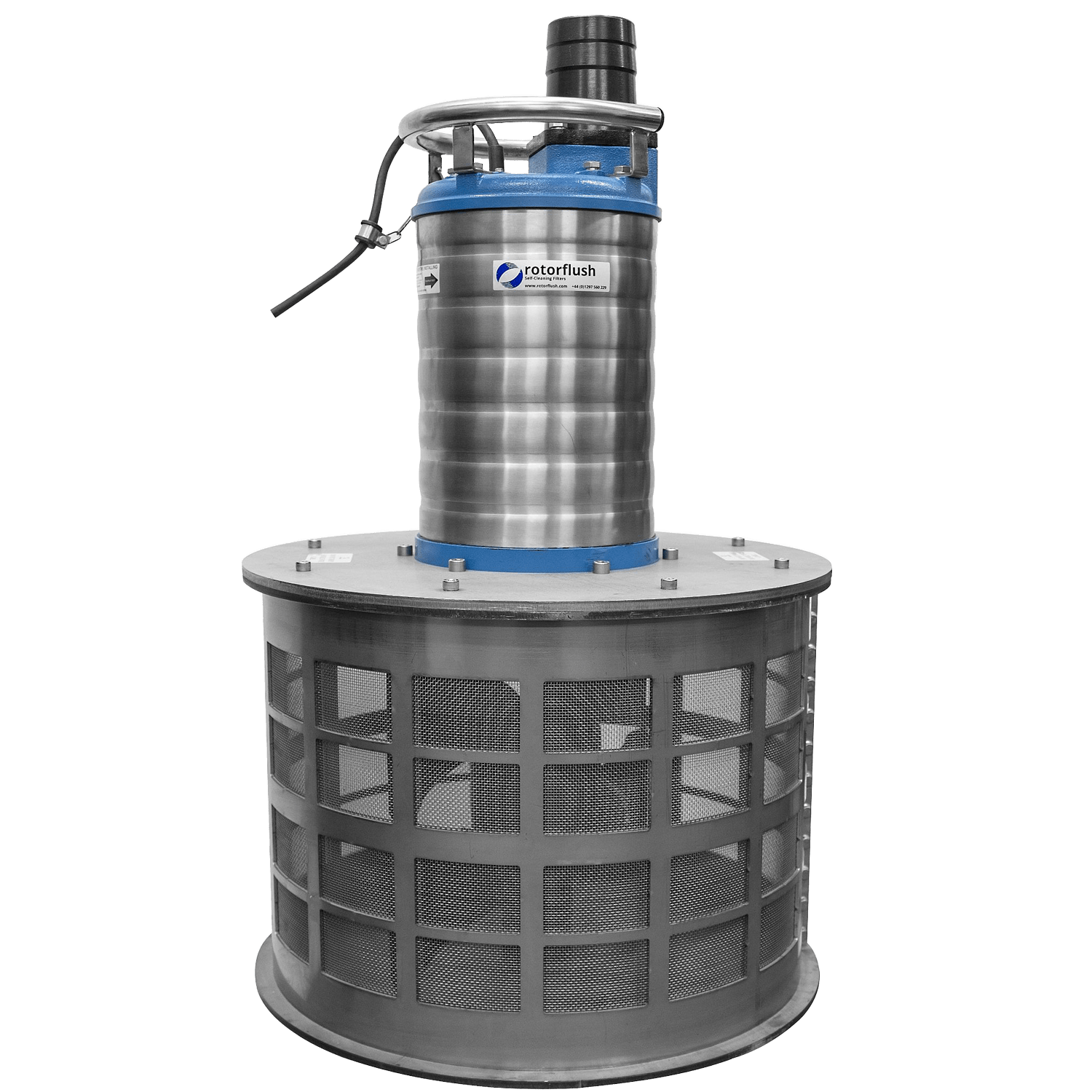

Rotorflush self-cleaning intake filters and submersible pumps with built-in self-cleaning intakes can be an essential component of a remote livestock watering system.

Best practice for Livestock Watering

Rotorflush filtration products are invaluable for good livestock water management.

Good livestock watering management requires investment, organization and forward planning. The Northern Ireland Department of Agriculture, Environment and Rural Affairs (DAERA-NI) offers the following advice:

“Farmers should develop contingency plans to get water to all stock in the event that water will be turned off. In many cases, this will mean having sufficient stores and a means of getting it to the animals – a storage facility and a pumping system.”

Farmers are also encouraged to make sure that all pumps and pipework are in good working order, and all tanks are leak-proof, and aim to conserve water as much as possible.

Sourcing water for livestock watering can mean abstracting raw water from streams, ponds or other natural water sources. Mains water is expensive, so making the best use of rainwater and recycling water where possible reduces costs. Pumps, water trough ball valves and other equipment can easily become blocked or jammed by weed, debris and other water born solids. Water often needs to be cleaned before re-use.

Rotorflush self-cleaning strainers and submersible filter-pumps provide robust low maintenance filtration and pumping while protecting and extending the life of your equipment. We have supplied many farmers in the UK and abroad with pumps and strainers that enable them to conserve water and reduce the time and effort that spent unblocking filters and repairing equipment.

The Rotorflush Self-cleaning Filter was invented by a dairy farmer. Our filters and filter pumps can help farmers put in place the systems they require for effective, safe and reliable livestock watering.

The Best Submersible Pumps for Livestock Watering

The Best Submersible Irrigation Pumps are those that require the least maintenance. Rotorflush continuously rated submersible centrifugal pumps are designed to screen water as they pump.

Their integral self-cleaning pump suction intake screen automatically backwashes to prevent blocking at the intake - all your other equipment is also protected from debris and particulate that might otherwise clog your livestock watering systems.

The Best Livestock Watering Pump Strainers and Intake Screens

Not all watering systems are suited to the use of submersible filter pumps. Dry mounted pumps are often used - the suction intake hose drawing directly from the water source.

Preventing the pump, and as just importantly, pipes valves, and jets from blocking requires filters on your livestock watering pump intake. Rotorflush manufacture ranges of self-cleaning suction intake filters, strainers and screens for use with dry mounted pumps. These self-cleaning intakes can screen out particulate down to 60 microns and cover a wide range of flow rates and capacities. Livestock watering made easy.

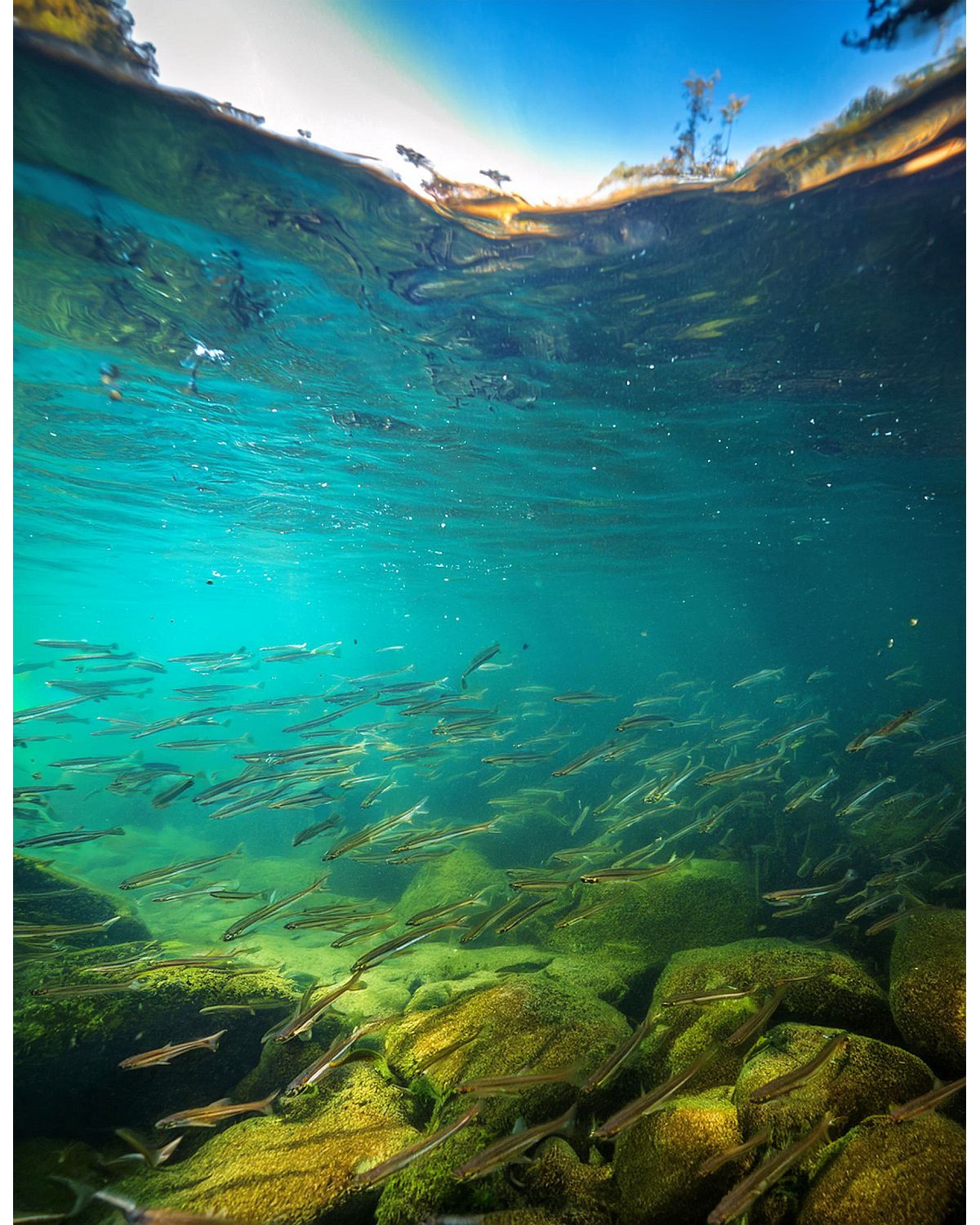

Environmental Regulations

How to comply with Regulations for Fish and Eel Screening?

Abstracting water from rivers, lakes and ponds is an increasingly regulated activity.

Often conditions apply. These may set limits on the amount of water being drawn, and may require water users to put in measures to protect fish fry, smolt, elvers and eels.

Fish fry and elver protections apply for most water abstraction of more than 20 cubic metres a day. The UK Environment Agency can advise and may limit the intake velocity to screens and pumps, and fix a mesh size to be used.

In the US the EPA has introduced fish protection measures that include setting similar limits on cooling water intakes.

FAQs About Rotorflush Products for Livestock Watering

Rotorflush self-cleaning filtration products are used for separating solids from dirty and contaminated water so that pumps, spray bars, irrigation and other equipment does not block or clog. Typical uses are:

- Screening and pumping water from lakes, ponds and rivers

- Screening and pumping dairy run-off from lagoons or settlement tanks

- Filtering water ahead of irrigation equipment

- Complying with Eel regulations when abstracting raw water.

Livestock watering from natural water sources typically involves abstracting water from a steam, lake, pond to supply cattle troughs. To ensure a good and reliable supply of fresh water as needed some type of screening on the pump suction intake is recommended. This will protect the pump from clogging if there is excess weed, leaves or other debris in the water. It will also help prevent blockages to ball valves or similar equipment. A self-cleaning suction intake filter or strainer is ideal.

All of our self-cleaning intake screens are specified to suit required flow rates, for instance filter pumps are recommended based on the flow rate and pressure your system needs and intake strainers and screens are specified according to the maximum flow through that is required.

Consideration should be given to what mesh size you need - top tip, go for the largest mesh size you can get away with to minimise maintenance. This will be determined by the smallest aperture the water you are drawing needs to go through, for example a 3 mm irrigation nozzle or spray bar aperture.

If you need advice or more information, please get in touch.

Increasingly, the Environment Agency makes taking steps to protect eels a condition of abstraction licences in England and Wales. These environmental regulations may have a bearing on the type of filter pump or strainer you need.

Our Products can be sized to account for Eel Regulations or EPA rule 316(b) if applicable, so that intake velocity and mesh size meet regulatory requirements for the flow rate you require.

Use of our products in sludge from bio-digesters, raw sewage or livestock slurry is not recommended.

Our strainers and filter pumps are ideal where the medium is dirty water contaminated with organic and fibrous particulate but only so long as the liquid is equal to or very near the viscosity of water.

Animal slurry and bio-digestate are too thick and concentrated for our self-cleaning screens to work effectively.

Not every submersible pump is suitable to be turned into a filter pump.

When we manufacture a filter pump we re-engineer the pump to have an additional impeller to provide the wash water to the screen without sacrificing the output of the pump.

Re-engineering a pump can often invalidate its warranty. Therefore, we would highly recommend that you opt for one of our Filterpumps™ that come with their own 1-year warranty.

If however, you have a particular pump that you would like to be made into a filter pump, please contact us to discuss.

Yes – because our products pump and filter directly from a dirty water source, there is less need for expensive in-line filtration. All our products have built-in self-cleaning back-washes that prevent intake screens from blocking, keep pumps clear and protect other connected equipment. This reduces maintenance, minimises downtime and can extend the life of pumps.

Browse Products

Idrogo Filterpumps™

Rotorflush Idrogo Filterpumps™. Medium-head submersible filter pumps with built-in self-cleaning filter on their intake. Stainless steel bodied pumps, ideal for domestic and small scale industrial use, delivering up to 120 litres per minute, maximum head 80 metres.

- Maximum Output 120 L/Min

- Maximum Head 80 m

Price from: £3,045

RF300 Self-cleaning Filters

RF300 self-cleaning filters. RF300 self-cleaning filters provide effective screening for surface mounted pump intakes. The RF200 pump suction hose filters can screen from 50 microns - 6 mm, handling up to 560 litres a minute, 148 US GPM. A continuous backwash keeps the intake screen clear.

- Screen Up to 560 L/Min, 148 US GPM

- Filter From 3 mm Down to 50 Microns

- Down to 230 US Mesh

Price from: £2,760

Nauti 60Hz Filterpumps™

Rotorflush Nauti Filterpumps™. Now available in 60 Hz supple High-head submersible filter pumps with built-in self-cleaning filters on the suction intake. They have a maximum output of 60 USGPM, and can pump up to 375 ft. Pumping and filtration are combined. All stainless steel construction.

- Maximum Output 60 USGPM

- Maximum Head 375 ft

Price from: £2,840

RF400 Self-cleaning Filters

RF400 Self-cleaning Filters. Self-cleaning Industrial Water Filters and Strainers. Extremely tough, stainless steel RF400 self-cleaning basket filters are for use on the pump suction hose of surface mounted pumps. The RF400 can filter up to 1000 litres per minute, 265 US GPM, from 50 microns to 6 mm.

- Screen Up to 1000 L/Min, 265 US GPM

- Filter From 6 mm Down to 50 Microns

- US Mesh 3 Down to 230

Price from: £4,070

RF600AR Self-cleaning Strainer

RF600AR Self-cleaning Industrial Water Filters and Strainers. Our RF600 self-cleaning intake strainers are for attachment to the suction hose of surface mounted pumps. These all stainless-steel construction mechanical filters can deliver up to 376 m3/hour, 1660 US GPM

- Screen up to 376 m3 / hour, 1660 US GPM

- Filter from 6 mm down to 315 microns

- US Mesh 3 down to 50

Price from: £8,730

Cobalt 400 Filterpumps™

Rotorflush Cobalt 400 Filter Pumps. Industrial low to medium pressure submersible pumps with an integral self-cleaning filter on the suction intake. These robust filter pumps offer high volume pumping and screening - up to 75 m3 / hr, 330 US GPM.

- Maximum Output - 60 m3 / hr, 265 US GPM

- Maximum Head - 19 m, 62 ft

Price from: £8,980

RUBI 400 Filterpumps™

Industrial Submersible Water Pumps with a Built-in Self-cleaning Suction Intake Screen. RUBI Filterpumps™ are extremely tough filter pumps, suitable for heavy industrial applications. They will pump and screen up to 1000 litres a minute, 528 US GPM, and have a maximum head of 10.2 bar, 145 psi.

- Maximum output - 60 m3 / hr

- Maximum head - 102 m

Price from: £11,780

Topaz 400 Filterpumps™

Rotorflush Topaz Filterpumps™. Medium head general purpose submersible filter pumps with integral self-cleaning suction intakes. They combine pumping and screening, delivering up to 60 m3/hr, 265 US GPM - and to a maximum head of 3.3 bar, 47 psi.

- Maximum output - 60 m3/hr, 265 US GPM

- Maximum head - 33 m, 108 ft

Price from: £8,730

Cobalt 600 Filterpumps™

Industrial Submersible Water Pumps with a Built-in Self-cleaning Suction Intake Screen. These Rotorflush Cobalt 600 filter pumps are low to medium pressure, robust filter pumps offering high volume pumping and screening - up to 108 m3 / hr, 475 US GPM.

- Maximum Output - 108 m3 / hr, 475 US GPM

- Maximum Head - 30 m, 98 ft

Price from: £16,090

Why Rotorflush?

UK Designed and Manufactured

Talk to our friendly team of engineers to discuss your design requirements.

- Built to your water output

- Filter down to 3 microns

- Hand built in the UK

Leading Water Filter Experts

Talk to our friendly team of engineers to discuss your design requirements.

- Industry experts for 20 years

- 200 installations

- Installed worldwide

Worldwide Delivery and Service

Through our worldwide distribution network we offer the ability to:

- Deliver filter pumps worldwide

- Help service your filter pump

- Repair broken filter pumps

Talk to an Expert About Your Project

Call us now on 01297 560 229

or Email sales@rotorflush.com

and a member of our expert, friendly team will call you back and find the self-cleaning filter, strainer or filter pump to suit your needs.

- We work with you to identify your issues

- We can design & build a custom solution

- We can deliver our solution worldwide

Use this form to get in touch or send us Feedback about your Rotorflush experience

or Email feedback@rotorflush.com

Rotorflush Workshop on the leafy Dorset Devon border.

Arrange a call back

Get the Filter Pump Your Project Requires. Talk to Our Friendly Team

This website uses cookies to ensure you get the best experience. Learn more