Learn More

Liquid Solids Separation

Liquid Solids Separator Systems

Essentially, liquid solid separation is the separation of solid from liquid in a suspension. Liquid solid separation is a critical process in various industries, including water treatment, food processing, and chemical manufacturing. How liquids and solids are separated will depend on the application. For example, you may wish to:

- recover solid material from waste water

- recover or recycle liquid, removing and discarding solids

- recover and re-use both solid and liquid

- recover both solid and liquid for separate disposal

Systems designed for liquid solids separation need to account for many factors – the nature and qualities of the suspension to be separated, solids concentration, solids separation, and any treatments required to aid the separation, before and after.

There are many existing and emerging technologies and methods being used and developed in this field. A brief overview of the most common separation methods follows.

What We Can Supply

Rotorflush Filters Ltd manufacture and supply a range of self-cleaning filtration equipment across many industrial sectors where there is a need for reliable low maintenance water quality management.

Our products are designed for liquids solids separation on open systems and water sources where there is a need to clean, filter, or separate water from particulate debris and other contaminating material.

All our filtration products incorporate self-cleaning technology that ensures low maintenance and allows water to be screened without interrupting the flow. Our self-cleaning filters can deliver a continuous supply of screened water filtered down to 60 microns.

Our liquid solids separators are built to order to a modular design and can be scaled and adapted to suit your particular application.

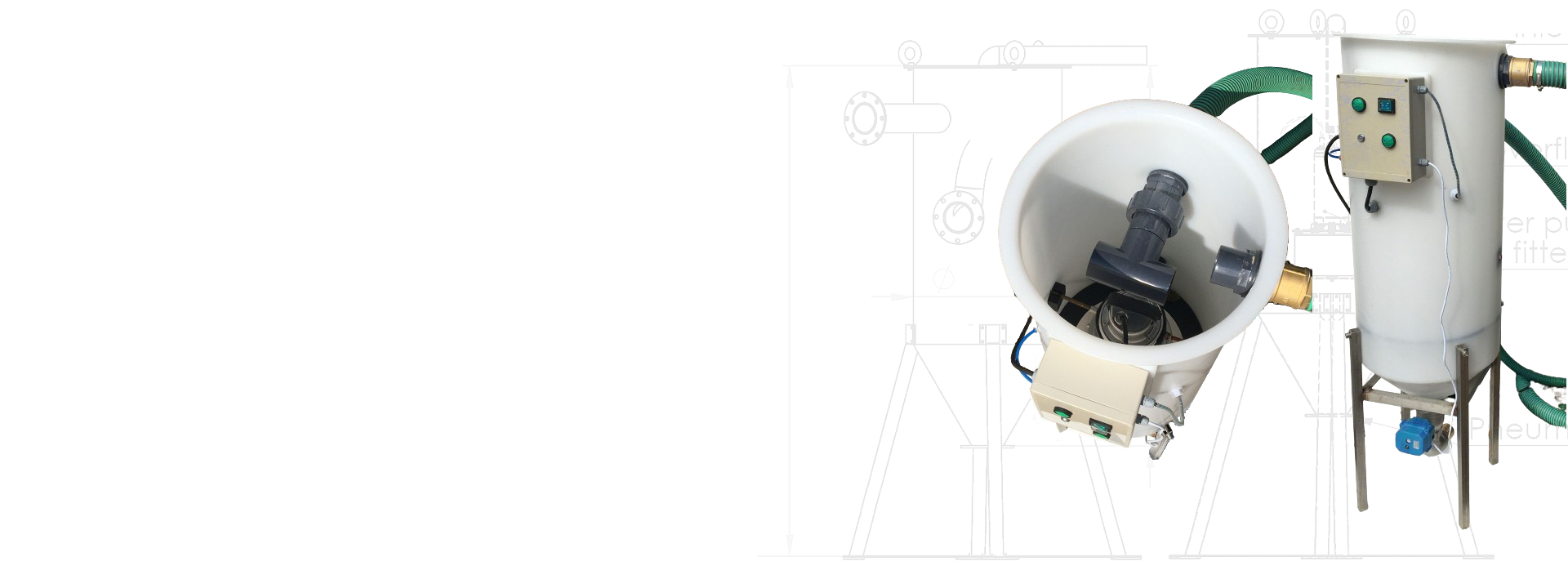

Rotorflush Separation Products

Rotorflush GT Liquid Solid Separators

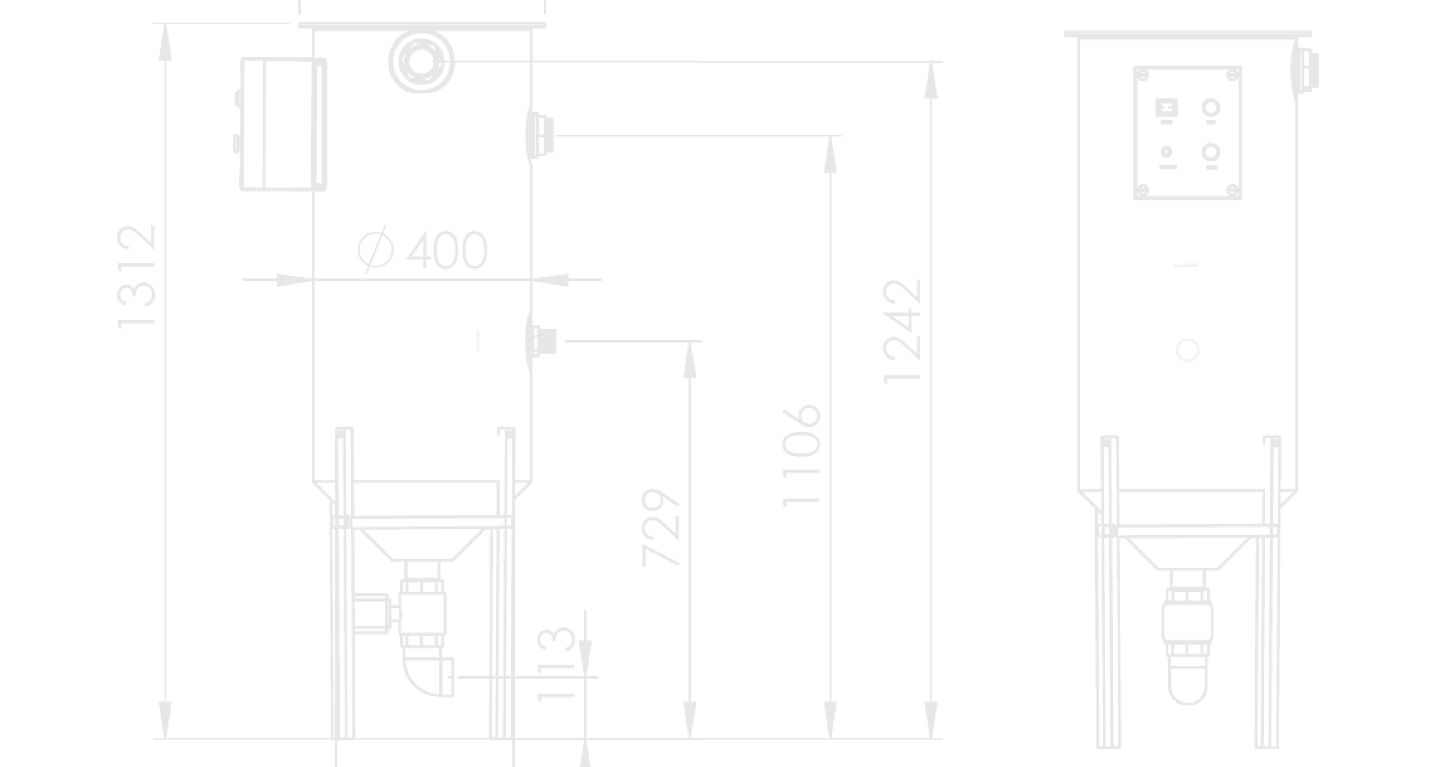

Rotorflush Liquid Solids Separators all share a modular design that can be scaled to suit different flow rates. The separator consists of a tank containing a self-cleaning filter pump. Water flowing to the separator is filtered; the output from the separator is filtered water, any solids or debris screened out of the water collect in the base of the separator, and are purged at intervals.

Rotorflush separators are simple to set up and operate, and allow particulate removal to be efficiently incorporated into open systems where water needs to be cleaned ahead of disposal or re-use. Our separator systems are semi-automated - solids can be purged at pre-set timed intervals – and flow rates are managed by overflow and float switch.

A solids collection option is available for easy solid waste management, recycling as much waste water as possible.

Our standard size is the GT200 separator.

Frequently Asked Questions

Rotorflush Liquid Solids Separators remove particulate and debris from contaminated water as water is being pumped or moved for use or disposal. The system allows continuous water flow and filtration down to as little as 50 microns. It is designed for liquid solid separation in open systems, rather than closed (usually pressurised) in-line systems of water use and management.

Particulate removed from the water is collected in the separator and purged at intervals. The system contains a self-cleaning filter to keep maintenance and downtime to a minimum

The benefits are:

- Good water economy - water can be re-used.

- Easy solids removal and waste management.

- Low maintenance and ease of use.

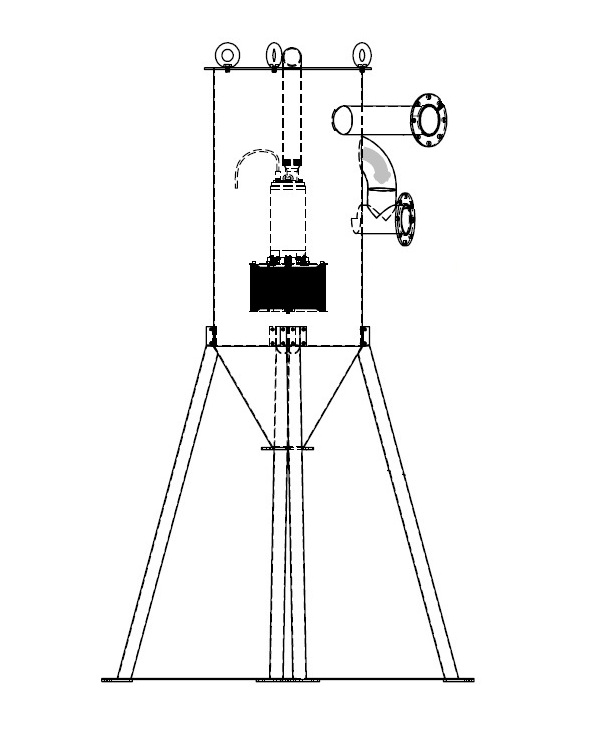

See a diagram showing how the GT200 Separator works - connections in and out and how the self-cleaning filterpump works.

Methods and Technology for Liquid Solids Separation

Liquid Solids Separation Techniques

- Filtration is one of the most common methods for separating solids from liquids. It involves passing a liquid through a filter medium that retains solid particles while allowing the liquid to pass through. Various types of filters can be used, including mesh filters, paper filters, membrane filters, and sand filters.

- Sedimentation relies on gravity to separate heavier solid particles from a liquid. In this method, the mixture is allowed to sit undisturbed so that the solids settle at the bottom of the container over time. The clear liquid can then be decanted or siphoned off.

- Centrifugation uses centrifugal force to accelerate the sedimentation process. By spinning the mixture at high speeds in a centrifuge, denser solid particles are forced to the bottom of the container more quickly than they would settle under gravity alone.

- Flotation is a method that separates solid particles based on their buoyancy. Air bubbles are introduced into the liquid, attaching to solid particles and causing them to rise to the surface, where they can be skimmed off.

- Magnetic Separation utilizes magnetic fields to separate magnetic materials from non-magnetic ones in a mixture. It is particularly useful in recycling processes or when dealing with ferrous materials.

- Hydrocyclones use centrifugal forces generated by fluid flow within a conical chamber to separate solids from liquids based on density differences. This method is effective for separating fine particles and is commonly used in mineral processing.

- Pressure filtration involves applying pressure to force liquid through a filter medium while retaining solids on one side of the filter. This method enhances filtration speed and efficiency compared to gravity filtration.

- Vacuum filtration is where a vacuum is applied on one side of the filter medium, creating suction that draws liquid through while retaining solids on top of the filter material. This method is efficient for separating fine solids from liquids.

- Crystallization separates dissolved solids from liquids by cooling or evaporating the solvent until it becomes saturated with solute, leading to crystal formation which can then be filtered out.

- Membrane separation techniques involve using semi-permeable membranes that allow certain molecules or ions to pass while blocking others based on size or charge differences. Common applications include reverse osmosis and ultrafiltration.

Rotorflush Liquid Solids Separation

Rotorflush Filters Ltd are primarily concerned with the practical filtration of water contaminated with suspended solids.

Rotorflush liquid solids separators are designed to filter out suspended solids that could block water pipes, pumps, irrigation nozzles heat exchangers - any equipment using and managing water where there is a low tolerance for particulate.

To this end, Rotorflush liquid solids separators use filtration and sedimentation as their main means of separation, although their unique design does incorporate some aspects of centrifugation.

Talk to an Expert About Your Project

Call us now on 01297 560 229

or Email sales@rotorflush.com

and a member of our expert, friendly team will call you back to discuss the right filtration for your analyser.

- We work with you to identify your issues

- We can design & build a custom solution

- We can deliver our solution worldwide

Use this form to get in touch or send us Feedback about your Rotorflush experience

or Email feedback@rotorflush.com

Rotorflush Workshop on the leafy Dorset Devon border.

Arrange a call back

Talk to our friendly team about liquid solids separation.

This website uses cookies to ensure you get the best experience. Learn more