Learn More

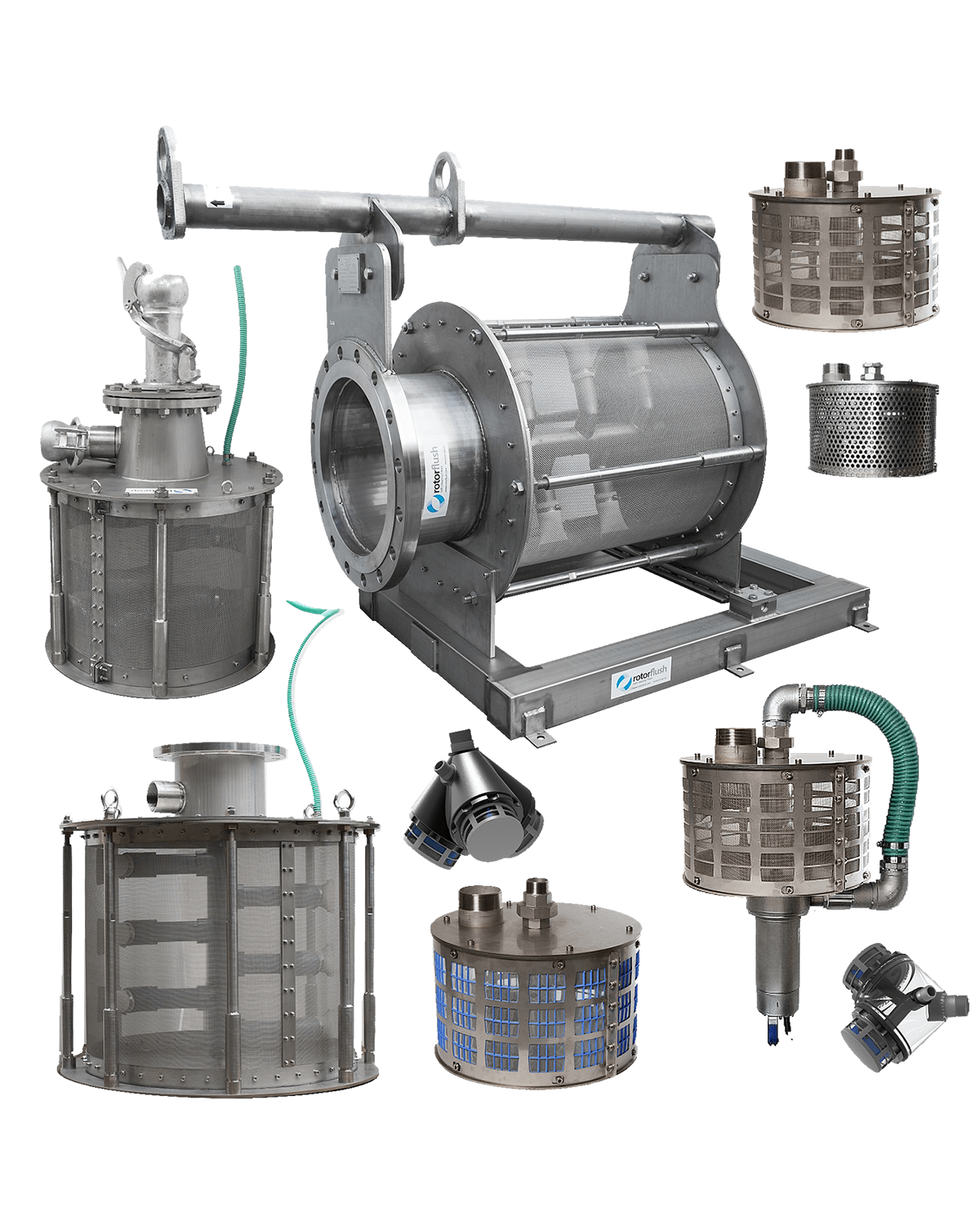

Rotorflush Filterpumps™ and Self-cleaning Filters for Farming

Our award-winning Rotorflush Self-cleaning filter system was invented by a dairy farmer fed up with having to unblock pumps and clogged strainers on his farm.

Water Management and Agriculture

Farmers know the importance of good water management on the farm, and know which agricultural pumps and strainers work best for them. Water pumps for farming need to be robust and operate in harsh conditions in all weathers. Keeping pumps working well and preventing blockages in farm water systems requires reliable, easy to maintain agricultural water filters.

What are water pumps for farming and agricultural water filters are typically used for?

Rotorflush agriculture pumps and filters are designed to work directly in a water source, pumping and screening are combined at the point of intake.

How are Pumps and Pump Strainers for Agriculture Used?

Farm Dirty Water Irrigation Systems

Dirty water run-off from yards, milking parlours and livestock units is usually collected in a lagoon, settlement tank or a slurry pit with a weeping wall system. Slurry lagoons and settlement tanks usually contain more water than manure, but particulate and suspended solids are high. That is why agricultural pumps and filters, pipelines or irrigation nozzles easily block when pumping dirty water back to land.

Farm water systems often use solids handling pumps such as progressive cavity pumps and peristaltic pumps to move dirty water with limited success. Our irrigation water filters and filter pumps screen out suspended solids at source, concentrating solids in lagoons and tanks. This is because Rotorflush submersible filterpumps™ have an integral self-cleaning suction strainer that keeps the filter mesh and pump clear whenever the pump is in operation. Pumps, and irrigation system equipment further down the line, are protected from blocking.

Time and time again, Rotorflush filter pumps and self-cleaning filters have proved more effective for irrigation than peristaltic pumps, progressive cavity pumps and static basket strainers. Pump, screen and irrigate more water without clogging your irrigation system; get fewer visits from the slurry tanker, less cost and maintenance, and better dirty water management.

Live Stock Watering

Raising livestock requires a lot of water. Sourcing water for livestock watering can mean abstracting raw water from streams, ponds or other natural water sources. Mains water is expensive, so making the best use of raw water, rainwater and recycling water where possible reduces costs.

The Rotorflush Self-cleaning Filter was invented by a dairy farmer. Our filters and filter pumps can help farmers put in place the systems they require for effective, safe and reliable livestock watering.

Irrigation

Irrigation Pumps and Irrigation Pump Strainers

Irrigation is integral to agriculture; crops need water. Effective irrigation requires good water management, and the selection of the best irrigation equipment for type of land, crop and water supply.

The award-winning Rotorflush Self-cleaning filter system has its origins in irrigation for agriculture. The first strainers and screens were developed specifically to return dirty water on dairy farms back to land - no one wants to tanker dirty water away.

Rotorflush self-cleaning irrigation water intakes and filter pumps help keep irrigation equipment clear from blockage by weed and other water-borne debris, reducing maintenance and downtime. Irrigation companies love our self-cleaning filters - good for crops, golf courses, garden centres and good for their customers.

Vegetable Washing at Laleham Farm

Charlie said that the filters are “one of the most significant investments we’ve made” giving the “biggest continuing result” of any equipment.

Rotorflush Sales Team

Rotorflush Filters LtdVegetable washing water accumulates in a small lagoon that feeds into settlement tanks before being pumped out again for the next round of washing, this often causes blockages with his existing equipment.

Using a Rotorflush self-cleaning strainer the majority of the water used is recycled, water costs are considerably lower.

Read the Full Case StudyEnvironmental Compliance - How Pumps and Filters Can Help

Regulations concerning the management of water in agriculture are continually evolving. Farms have to comply with national and local environmental regulations concerning the management of water and disposal of waste water.

Environmental regulations affect the abstraction of water from rivers lakes and ponds, and how water is returned to land or back to waterways.

Farmers often have to comply with regulations to protect elvers and fish fry when drawing raw water. Fish and eel screening regulations require farmers to use equipment that reduces the intake velocity of their raw water intakes, and to filter water to protect aquatic life. Rotorflush filters and filter pumps are recommended for compliance when pumping raw water.

Waste water from farms and agricultural activity is very strictly controlled. In many jurisdictions, there are strict regulations governing the discharge of any form of wastewater into natural water bodies. These regulations are designed to protect water quality and public health. Guidelines are detailed and comprehensive.

Best practice recommends that instead of discharging agricultural wastewater directly into rivers or lakes farmers can avoid breaching regulations store water in sedimentation ponds, construct wetlands or biologically treat water to help reduce suspended solids and other contaminants before disposal. Capturing and recycling waste water is also advised.

Managing stored waste agricultural water is not without its difficulties. Fortunately, Rotorflush filtration products and pumps are designed for exactly this - screening and pumping dirty water contaminated with debris and suspended solids.

The Best Submersible Pumps for Agriculture and Farming

The Best Submersible Pumps for Agriculture and Farming are those that require the least maintenance. Rotorflush continuously rated submersible centrifugal farming water pumps are designed to screen water as they pump.

Water can be screened for debris, weed and muck as it is pumped. This is because they have an in-built self-cleaning mechanism on the suction intake that keeps the intake strainer clear while pumping. The pump suction intake screen is automatically backwashed to prevent blocking at the intake - and, all your other connected equipment is also protected from debris and particulate that might otherwise clog your farm water systems.

The Best Pump Strainers and Intake Screens for Agriculture

Not all farming water systems and applications are suited to the use of submersible pumps. Dry mounted pumps are often used - the suction intake hose drawing directly from the water source. Pumping from lagoons, storage tanks, shallow streams and ponds - all these applications may require a surface mounted pump.

Preventing the pump, and as just importantly, feeds and nozzles from blocking requires a filter or strainer on your pump intake. Rotorflush manufacture ranges of self-cleaning suction intake filters, strainers and screens for use with dry mounted pumps. These self-cleaning intakes can screen out particulate down to 60 microns and cover a wide range of flow rates and capacities. Moving dirty water made easy!

FAQs About Rotorflush Products for Agriculture and Farming

Rotorflush self-cleaning filtration products are used for separating solids from dirty and contaminated water so that pumps, spray bars, irrigation and other equipment does not block or clog. Typical uses are:

- Screening and pumping water from lakes, ponds and rivers

- Screening and pumping dairy run-off from lagoons or settlement tanks

- Filtering water ahead of irrigation equipment

- Complying with Eel regulations when abstracting raw water

All of our self-cleaning intake screens are specified to suit required flow rates, for instance filter pumps are recommended based on the flow rate and pressure your system needs and intake strainers and screens are specified according to the maximum flow through that is required.

Consideration should be given to what mesh size you need - top tip, go for the largest mesh size you can get away with to minimise maintenance. This will be determined by the smallest aperture the water you are drawing needs to go through, for example a 3 mm irrigation nozzle or spray bar aperture.

If you need advice or more information please get in touch.

Increasingly, the Environment Agency makes taking steps to protect eels a condition of abstraction licences in England and Wales. These environmental regulations may have a bearing on the type of filter pump or strainer you need.

Our Products can be sized to account for Eel Regulations or EPA rule 316(b) if applicable, so that intake velocity and mesh size meet regulatory requirements for the flow rate you require.

Use of our products in sludge from bio-digesters, raw sewage or livestock slurry is not recommended.

Our strainers and filter pumps are ideal where the medium is dirty water contaminated with organic and fibrous particulate but only so long as the liquid is equal to or very near the viscosity of water.

Animal slurry and bio-digestate are too thick and concentrated for our self-cleaning screens to work effectively.

Not every submersible pump is suitable to be turned into a filter pump.

When we manufacture a filter pump we re-engineer the pump to have an additional impeller to provide the wash water to the screen without sacrificing the output of the pump.

Re-engineering a pump can often invalidate its warranty. Therefore, we would highly recommend that you opt for one of our Filterpumps™ that come with their own 1-year warranty.

If however you have a particular pump that you would like to be made into a filter pump, please contact us to discuss.

Yes – because our products pump and filter directly from a dirty water source, there is less need for expensive in-line filtration. All our products have built-in self-cleaning back-washes that prevent intake screens from blocking, keep pumps clear and protect other connected equipment. This reduces maintenance, minimises downtime and can extend the life of pumps.

Browse Products

Idrogo Filterpumps™

Rotorflush Idrogo Filterpumps™. Medium-head submersible filter pumps with built-in self-cleaning filter on their intake. Stainless steel bodied pumps, ideal for domestic and small scale industrial use, delivering up to 120 litres per minute, maximum head 80 metres.

- Maximum Output 120 L/Min

- Maximum Head 80 m

Price from: £3,045

Nauti Filterpumps™

Rotorflush Nauti Filterpumps™. High-head submersible filter pumps with built-in self-cleaning filters on the suction intake. They have a maximum output of 220 litres a minute, and can pump up to 10 bar. Pumping and filtration are combined. All stainless steel construction.

- Maximum Output 220 L/Min

- Maximum Head 103 m

Price from: £2,915

Nauti 60Hz Filterpumps™

Rotorflush Nauti Filterpumps™. Now available in 60 Hz supple High-head submersible filter pumps with built-in self-cleaning filters on the suction intake. They have a maximum output of 60 USGPM, and can pump up to 375 ft. Pumping and filtration are combined. All stainless steel construction.

- Maximum Output 60 USGPM

- Maximum Head 375 ft

Price from: £2,840

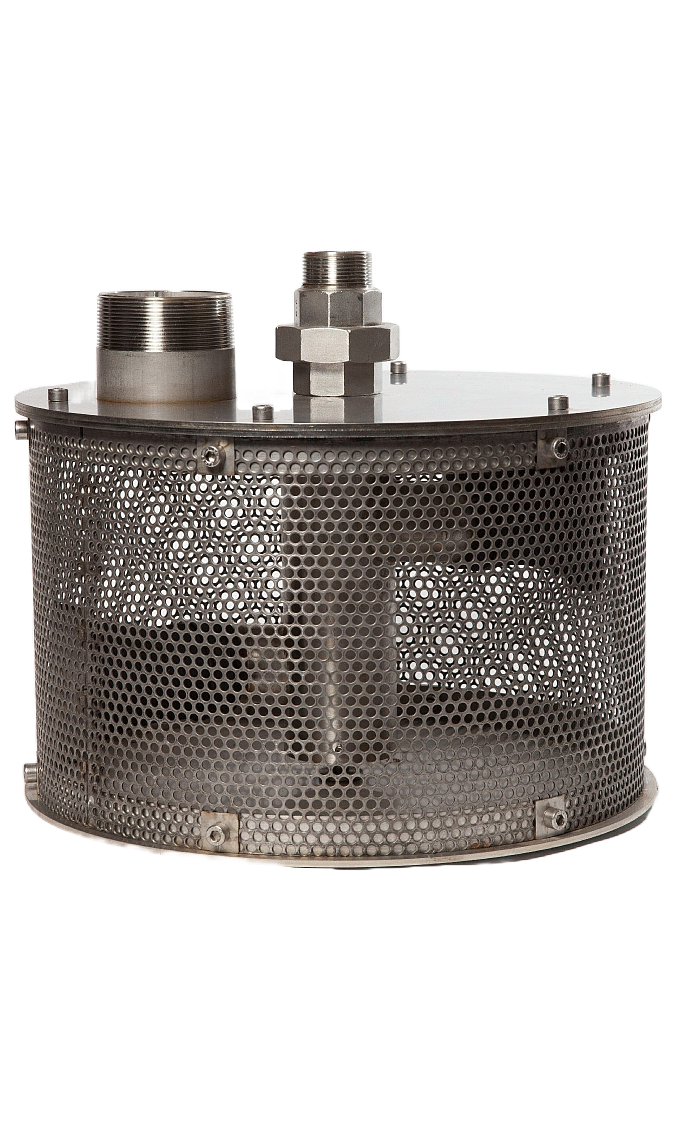

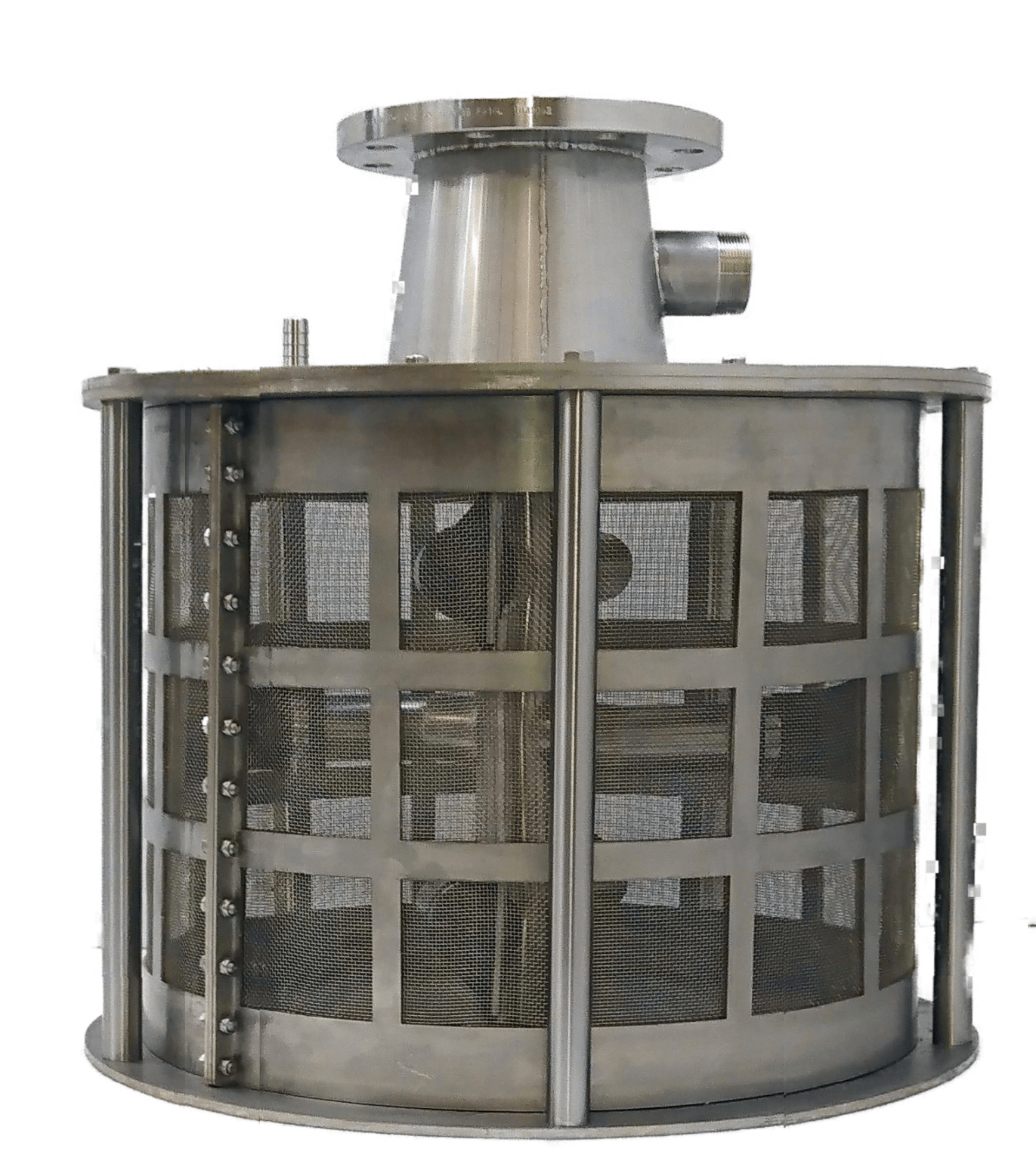

RF400 Self-cleaning Filters

RF400 Self-cleaning Filters. Self-cleaning Industrial Water Filters and Strainers. Extremely tough, stainless steel RF400 self-cleaning basket filters are for use on the pump suction hose of surface mounted pumps. The RF400 can filter up to 1000 litres per minute, 265 US GPM, from 50 microns to 6 mm.

- Screen Up to 1000 L/Min, 265 US GPM

- Filter From 6 mm Down to 50 Microns

- US Mesh 3 Down to 230

Price from: £4,070

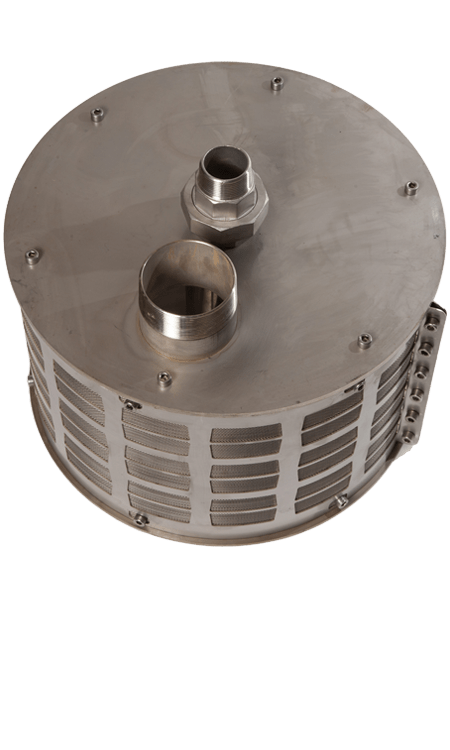

RF600AR Self-cleaning Strainer

RF600AR Self-cleaning Industrial Water Filters and Strainers. Our RF600 self-cleaning intake strainers are for attachment to the suction hose of surface mounted pumps. These all stainless-steel construction mechanical filters can deliver up to 376 m3/hour, 1660 US GPM

- Screen up to 376 m3 / hour, 1660 US GPM

- Filter from 6 mm down to 315 microns

- US Mesh 3 down to 50

Price from: £8,730

Cobalt 400 Filterpumps™

Rotorflush Cobalt 400 Filter Pumps. Industrial low to medium pressure submersible pumps with an integral self-cleaning filter on the suction intake. These robust filter pumps offer high volume pumping and screening - up to 75 m3 / hr, 330 US GPM.

- Maximum Output - 60 m3 / hr, 265 US GPM

- Maximum Head - 19 m, 62 ft

Price from: £8,980

RF800AR Self-cleaning Strainer

RF800AR Self-cleaning Industrial Filters and Strainers. Our RF800AR self-cleaning intake strainers are for attachment to the suction hose of surface mounted pumps. These tough, industrial, all stainless-steel construction mechanical filters can deliver up to 870 m3/hour, 3830 US GPM

- Screen up to 870 m3 / hour, 3830 US GPM

- Filter from 6 mm down to 1 mm

- US Mesh equivalent 3 down to 18

Price from: £0

Jasper Filterpumps™

Rotorflush Jasper Filterpumps™. Industrial submersible filter pumps with self-cleaning filter intakes. Low and medium head stainless steel pumps with a maximum output of 1000 l/min and a maximum head of 35 metres. Corrosion resistant 316 stainless steel versions are also available for use in brackish water, seawater and harsh industrial conditions.

- Maximum Output – 1000 L/Min

- Maximum Head 35 m

Price from: £8,580

RF600LW Self-cleaning Filters

Self-cleaning Industrial Water Filters and Strainers. The RF600LWs are robust stainless steel self-cleaning basket filters that protect pumps and other equipment from blocking and blinding when pumping dirty water. They are fitted with 1 mm - 6 mm stainless steel mesh screens, handling up to 730 m3/hour, 3,215 US GPM.

- Screen Up to 730 m3 / Hour, 3215 US GPM

- Filter From 6 mm Down to 1 mm

Price from: £9,845

Talk to an Expert About Your Project

Call us now on 01297 560 229

or Email sales@rotorflush.com

and a member of our expert, friendly team will call you back and find the self-cleaning filter, strainer or filter pump to suit your needs.

- We work with you to identify your issues

- We can design & build a custom solution

- We can deliver our solution worldwide

Use this form to get in touch or send us Feedback about your Rotorflush experience

or Email feedback@rotorflush.com

Rotorflush Workshop on the leafy Dorset Devon border.

Arrange a call back

Get the Filter Pump Your Project Requires. Talk to Our Friendly Team

This website uses cookies to ensure you get the best experience. Learn more