Rotorflush GT200 Liquid Solids Separator System

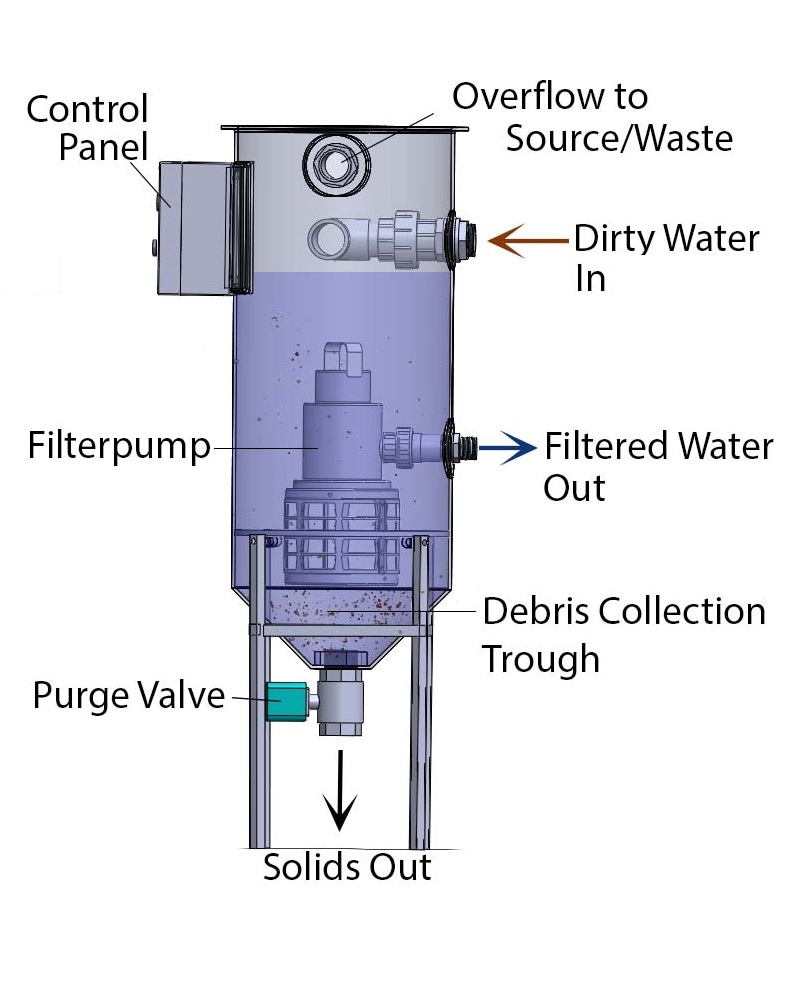

The Rotorflush GT200 Liquid Solids Separator provides an easy way to remove and dispose of particulate and solids when moving contaminated water. As water flows by gravity or is pumped into the GT200 liquid solids separator, the separator simultaneously filters out debris and pumps filtered water onwards. Debris and particulate left behind is purged from an outlet below the separator as required, either manually or automatically on a timer.

Key Features

Rotorflush GT200 Liquid Solids Separator System

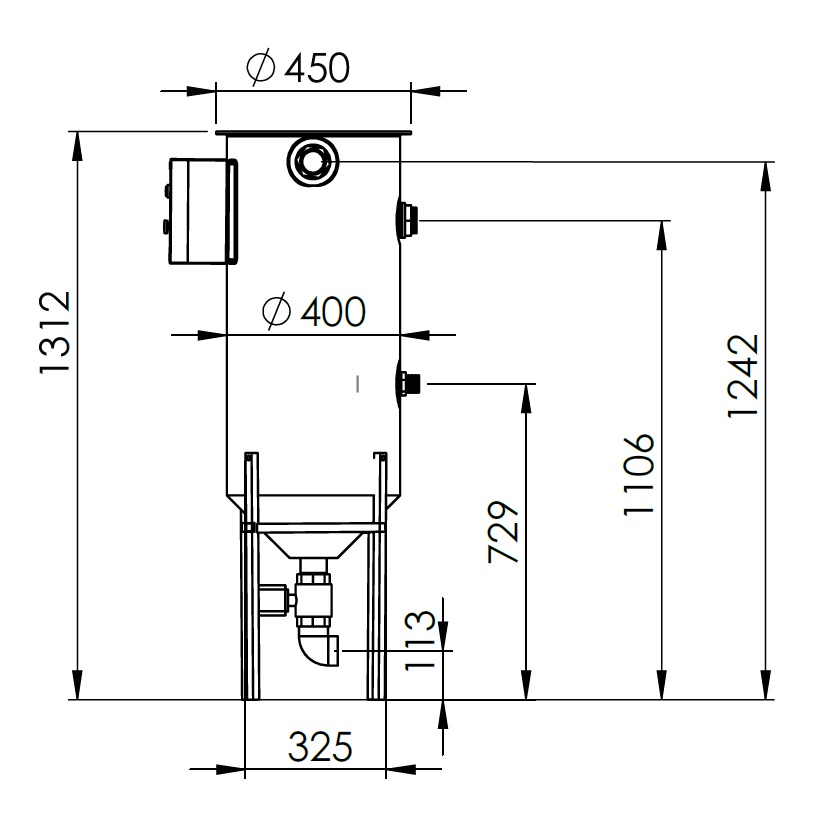

Specifications & Dimensions

Specification

Dimensions

Prices & ordering

- All Models

- GT200-O1608

- GT200-O2008 110v

- GT200-O25010

- GT200-O35012

Downloads

Learn More

How Does the Rotorflush Separator Work?

How Rotorflush Liquid Solids Separators Work

Our GT200 Liquid Solids Separators all incorporate Rotorflush’s unique and patented self-cleaning filter mechanism – it's how all Rotorflush self-cleaning filtration products work. Our separators take in dirty or contaminated water - this can be pumped to the separator from your water source using a solids handling pump or similar, or water can be gravity fed.

The tough medium density polyethylene (MDPE) separator tank contains a Rotorflush Filterpump™. The filter pump is a submersible pump with an integral self-cleaning suction intake screen - the filter pump filters and pumps simultaneously. Its self-cleaning suction intake filter can screen as low as 50 microns; filtered water is pumped out of the separator for you to use as required. Particulate and detritus screened out by the self-cleaning intake filter mesh remains in the separator and collects below the filterpump.

A purge valve at the base of the separator allows accumulated debris to be discharged for solids collection; water in the purge can be sent back to source or to drain. The purge can be automated to open at timed intervals for low maintenance operation, or operated manually.

Pumping water and screening water are combined in one powerful, low maintenance, easy to install separation tank, allowing for near continuous liquid solids separation.

General Information About Rotorflush Liquid Solids Separators

What are GT200 Liquid Solids Separators and How Can They Be Used?

Rotorflush GT200 Liquid Solids Separators are designed to screen out debris and particulate from water as it moves through the separator tank. The particulate left behind accumulates at the base of the tank until it is ejected. A purge valve at the base of the unit can be manually operated as required, or automatically operated by timer.

The separator tank contains a submersible pump with a built-in self-cleaning intake that can filter down to 50 microns. Cleaned water is pumped out of the separator for use elsewhere.

Water can be pumped into the separator or flow by gravity from a water source.

The GT200 separator is ideal for applications where water is being used and needs to be re-used. For example:

- Cleaning out tanks

- Cleaning water for re-use when pressure washing

- Waste water recovery and management

- Pre-filtration ahead of fine and ultra-fine filtration

- Separation for industrial processes across many industrial sectors

By recovering solid particles from liquids, each separated product can be reworked back into a process, saving money on disposal costs and raw materials.

An optional Solid Waste Handling add-on is available - contact us for more information.

What Mesh Sizes Can the GT200 Separators Be Fitted With?

Rotorflush GT200 Separators can be fitted with:

- Nylon Mesh inserts. Available in 60 micron, 115 micron, or 300 micron. - The filter mesh is made up of replaceable bias-cut nylon mesh offering a very clean filtration, ideal for sampling. The inserts are inexpensive and easy to replace.

- 316 Sintered Stainless Steel Mesh. Available in 50 micron, 100 micron, or 315 micron. - A robust 2-layer sintered steel screen that can be easily cleaned with a pressure washer. Ideal for screening water for heat pumps and other applications with small tolerances.

- 316 stainless Woven Mesh. Available in 1 mm, 2 mm, or 3 mm. - A coarse screen providing ultra-low maintenance cycles; filters and screens with coarse mesh come fitted with rubber backwash jets which are suitable for handling larger particles. Ideal difficult water conditions.

What’s the Best Way to Install and Use My Rotorflush GT200 Separator?

GT200 liquid solids separators should be installed on a flat, level surface. The separator will have in-built self-cleaning filtration using a Rotorflush filterpump.

Full instructions for set-up and operation are supplied with each unit, and Rotorflush Filters are happy to advise.

What Maintenance Does My Rotorflush GT200 Separator Need?

Although they are self-cleaning, all of our products will require a manual clean every once in a while. Self-cleaning filter pumps and filters inside the GT200 tank will be fitted with either nylon or stainless steel filter mesh.

The nylon mesh filter inserts are easily replaced, and stainless mesh can be cleaned with a pressure washer. How often depends on your mesh size and what you are filtering.

As a minimum we recommend the following:

- Mesh up to 115 micron should be cleaned or replaced every 1000 hours of use

- Mesh up to 315 micron should be cleaned or replaced every 5000 hours of use

- Coarse mesh that is 1 mm or bigger should be inspected and cleaned every 6 - 12 months

These guidelines are will vary with water quality. The GT200 tank should be thoroughly drained and cleaned at regular intervals to remove any build up of scale or bio-film over time. How often this is required will depend on local conditions.

Full maintenance guidelines can be found in the instruction manual available from the download link above.

Our Guarantee

All our products are guaranteed for a year. Full details in our Terms and Conditions.

Why Rotorflush?

Our Separators are Designed & Manufactured in the UK

All our products are made to order, and many can be made to customer specifications.

- Built to meet your requirements

- Screen dirty water down to 50 microns

- Made to order in the UK

Experts in Liquid Solids Separation, Water Screening and Filtration

Our products and expertise have been appreciated by satisfied customers for over 2 decades.

- Industry experts for over 20 years

- 1000's of products in use worldwide

- Our products keep water flowing by protecting pumps, screens, spray bars…….

- .…nozzles, heat exchangers and other connected equipment from blocking

Worldwide Delivery and Service

Through our worldwide distribution network and direct sales, we offer the ability to:

- Deliver filters and strainers worldwide

- Help service your filter or strainer

- Repair a broken filter or strainer (whatever you've done to it…)

Talk to Our Experienced Staff

Call us now on 01297 560 229 | 8am - 5pm GMT,

or Email sales@rotorflush.com and a member of our expert, friendly team will call you back and find the right liquid solids separation product for you.

- We work with you to identify your requirement

- We can design & build a custom solution

- We can deliver our solution worldwide

We’ll Help You Find the Right Separator for You

or tell us what liquid and solids you want your GT200 separator to handle.

This website uses cookies to ensure you get the best experience. Learn more