Self-cleaning Filters for Water Source Heat Pump Systems

Water Source Heat Pump System Intake Pumps and Filters

Find out….

- How an open loop water source heat pump system works

- How to filter water for a water source heat pump system

- What you need to know to choose the right intake pump for your system

How do Water Source Heat Pump Systems Work?

How an Open Loop Water Source Heat Pump System Works

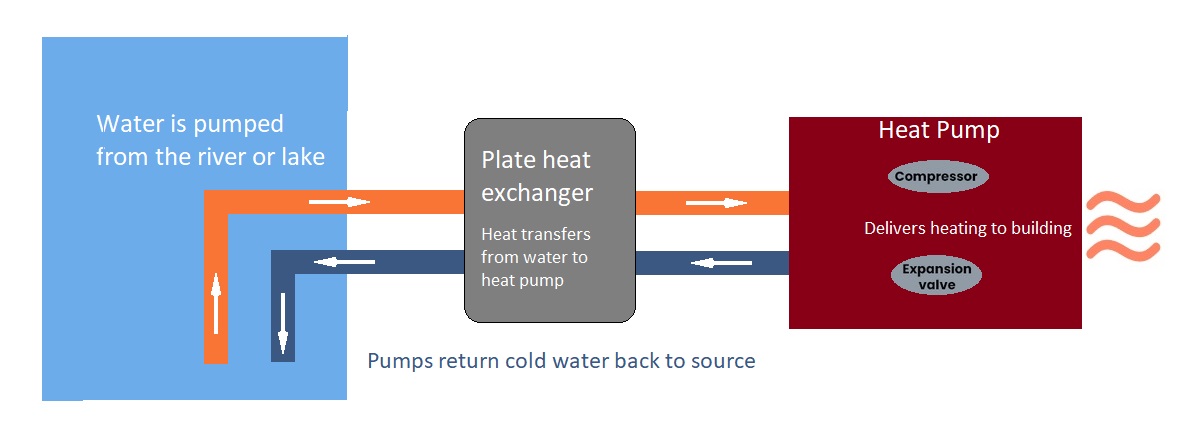

An open loop water source heat pump system utilizes a body of water, such as a lake, pond, or river, as a heat source. The system operates by drawing water directly from this source, passing it through a heat exchanger and heat pump, and then returning it to the source. This is also known as water to water heat pump system. Here’s a breakdown of the process:

Water Extraction:

The system pumps water from the water source into the heat pump. Rivers, lakes and ponds – particularly flowing water or larger expanses of still water – have their heat renewed constantly. The heat energy stored in the water is replenished every day by the sun.

Water is extracted by pumps and fed into the heat pump system. Rotorflush Filterpumps™ are ideal as they screen out any particulates, weed or other detritus that might interfere with the system

Heat Exchange:

Inside the heat pump, the water transfers its heat to a refrigerant, which is then compressed to increase its temperature. This process allows the heat to be used for heating a building or for domestic hot water. Although there are different kinds of heat pumps, they all work in the same way. Heat pumps transfer heat from the outside environment into a building through a four-step process:

- Evaporation

- Compression

- Condensation

- Expansion

This is known as a refrigeration cycle. The heat pump diagram illustrates the process.

Water Return:

After passing through the heat pump, the cooled water is returned to the original source, completing the cycle.

Open loop systems are known for their efficiency and simplicity, making them a popular choice for geothermal heating and cooling.

How Do I Filter Intake Water for my Water Source Heat Pump System?

Preventing Blockages in Open Loop Systems

To ensure the efficient operation of an open loop water source heat pump system, also called water to water heat pump system, and to prevent blockages, consider the following suggestions:

Regular Maintenance:

Schedule routine inspections and maintenance of the system to check for any signs of wear or blockage in the pipes and filters. This is unavoidable for any heat pump system, and is recommended annually, usually before the onset of winter.

Use of Filters:

Install filters to screen out material with the potential to block the narrow apertures typically found in heat exchangers. While screens and filters on the water intake or in-line within the system will screen out debris and particulate, they too may become blocked.

Rotorflush submersible pumps with their built-in self-cleaning intake will screen as water is pumped to your system. The Rotorflush filterpump intake screen benefits from a continuous backwash as water is pumped, to keep the intake clear, minimise maintenance and protect the heat pump system.

Water Quality Monitoring:

Regularly test or inspect the water source quality to ensure it is free from excessive sediments, algae, or other contaminants that could lead to blockages.

Seasonal Adjustments:

In colder months, ensure that the system is protected from freezing, which can cause ice blockages. Insulating pipes and using antifreeze solutions where necessary can help.

By implementing these preventive measures, you can maintain the efficiency of your open loop water source heat pump system and minimise the risk of blockages.

What Do I Need to Know to Choose an Intake Pump and Filter for my Water Source Heat Pump System?

Your heat pump system will be rated for a particular energy output, which determines the heat pump capacity required to meet this specification.

The flow rate you require will be an attribute of the heat pump.

The water you need to pump to your heating system will need to be delivered at a pressure that will allow the correct volume of water to flow through the system.

Pressure can be lost through pipework, the height from the water source to heat pump, and the manufacturer's stated pressure loss through the heat exchanger in your system. The pressure you need can be expressed in metres, bar or psi.

The pressure loss through pipework can be calculated, providing you know:

- the inside diameter of your delivery pipe

- the length of the delivery pipe

- how many right angle bends there are

An online pressure drop calculator such as http://www.pressure-drop.online/ will help.

Pipework pressure loss needs to be added to the height from the water source to heat pump, plus the pressure loss through the heat pump according to the manufacturer.

This will give you a value for Total Head, or the pressure loss through the system.

For water source open loop heat pump systems, a pump is required to pump water through the system.

The pump you need, which could be a surface-mounted pump or a submersible pump, will need to be able to deliver the flow rate the system requires at the total pressure the system requires. These two values will determine the most efficient pump for the system.

A submersible pump with a self-cleaning intake filter is a very good choice, because it will screen out any debris that might clog your heat pump system, while simultaneously maintaining the flow of water you need.

Open loop water source heat pump systems need some protection to prevent blockages in the pump, system pipework and heat exchangers.

A simple basket type strainer may be sufficient for screening out larger debris in a flowing water source.

In still or v slow moving water, and with a fine mesh, the strainer will rapidly block and starve the water-to-water heat pump system. Finer mesh may be required either because the apertures through the heat exchanger are very small and prone to clogging, or because there may be restrictions on water abstraction - for example a minimum mesh size to comply with environmental regulations for eel and fish protection.

The answer is to use a self-cleaning water intake, as incorporated in a submersible Rotorflush Filterpump™ or use a Rotorflush self-cleaning suction intake filter on the suction hose of a surface mounted pump.

A self-cleaning intake screening to 315 microns will protect most water source heat pump systems and greatly reduce the burden on any secondary filters down the line.

Self-cleaning Filtration from Rotorflush Filters Ltd

Mixed Self-Cleaning Filtration Products for Cooling Water And Water Source Heat Pump Intakes

Find out more or contact us today!

Get in touch for more information about Water source heat pumps and heat pump filters

For more information about how Rotorflush Submersible Pumps and Rotorflush Intake Screens with their unique and patented self-cleaning technology can protect your water source heat pump, contact the Rotorflush team