How to Stop Pump Inlet Screens from Blocking

Pump Inlet Screens

Pump Inlet Screen Types

There are two types of water Pump Inlet Screens, depending on the type and use of water pump.

There are Pump Inlet Screens for use with water pumps that are surface mounted or dry mounted and Pump Inlet Screens for water pumps that are submersible - operating in or underwater.

Pump Inlet Screens for Surface mounted Pumps

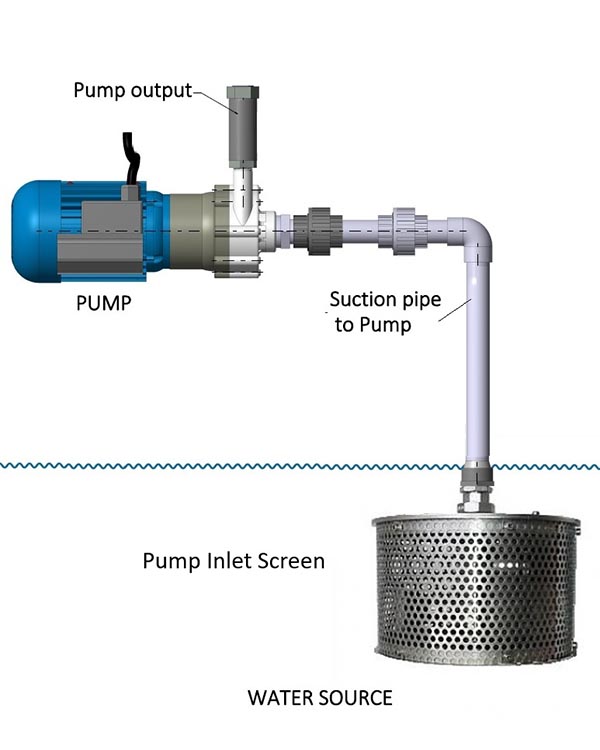

These pumps draw water from a source through a suction intake pipe in the water source. Typically, the Pump Inlet Screen for a surface mounted pump will be attached in water to the end of the pump suction hose. These are essentially basket strainers, which can easily block if the water source is contaminated with wed, debris and other solids in the water.

The finer the mesh, the more likely and frequently this type of Pump Inlet Screen will block. Unless the water being pumped is very clean, basic basket type Pump Inlet Screens will inevitably block; maintenance - that is unblocking the screens - is unavoidable and in many circumstances a frequent necessity.

Pump Inlet Screens for Submersible Pumps

Submersible pumps usually have some form of Pump Inlet Screen around their intake ahead of the impeller that drives water out of the pump. These screens are usually the same diameter as the pump body, and perforated to a size which is in keeping with the clearance through the submersible pump. This is to protect the pump from blocking.

Submersible pump inlet screens have a small surface area, yet the pumps can pull in a lot of water. Larger particulate and debris (for example autumn leaves) can very quickly block these intakes. Unblocking requires lifting the submersible pump and clearing the intake, usually interrupting the pump's operation.

Uses and Issues

The main function main of a pump inlet screen is to prevent pumps from blocking. The small area of screening, however, means screens can easily block up, interrupting flow and requiring frequent maintenance.

The size of mesh of most pump inlet screens is determined by the pumps they are protecting. The screen aperture will filter debris that exceeds the clearance of the pump impeller set. This protects the impellers from clogging and getting blocked, but large aperture coarse screening affects other equipment.

Protecting the pump does not always protect other equipment being supplied by the pump. For example, spray bars, irrigation nozzles or heat exchangers may have a lower tolerance of particulates than the pump, and may be susceptible to damage or blockage without finer screening.

There are other concerns and issues that affect choice of pump inlet screens. Regulations and requirements exist to protect fish and eel populations when pumping raw water from lakes, rivers and estuaries. Screening can be a condition of a water abstraction licence or use of water.

The biggest concern around pump inlet screens and screening water is usually cost. Having no screening can easily lead to blocked pumps and equipment failure. Pump inlet screens may protect against damage, but they too may block. The resulting downtime and maintenance effort to clear blocked intakes all costs money.

Preventing Pump Inlet Screens from Blocking

Screening is not necessary if the source water is very clean. This is rarely the case - water is pumped from rivers, the sea, lakes, ponds, lagoons, settlement tanks, and sumps. It may be pumped for use, re-use or disposal, but chances are unless it is tap water it will contain some level of suspended solids or particulate.

Screening can help, often as a primary filter ahead of finer filtration processes, depending on how clean the water is required to be. Screens by their very nature get blocked sooner or later, there is no filter yet invented that does not eventually block. The trick is to make sure that the intervals between maintenance are as long as possible.

Having a pump inlet screen that has a backwash, or a self-cleaning mechanism to remove debris from the pump inlet screen either at regular intervals or continuously greatly decreases the amount of unblocking and maintenance required for screens without this capability.

Self-cleaning Pump Inlet Screens will prevent blocking for much longer than plain screening.

Self-Cleaning Pump Inlet Screens

Of the few commercially available self-cleaning pump inlet screens, Rotorflush Filters Self-cleaning pump Inlet Screens are the perhaps the most robust and reliable. All stainless steel construction, these are simple mechanical suction intake filters that keep their mesh clear with a continuous backwash to repel debris, weed, detritus and suspended solids away from the inlet mesh.

Designed to operate whenever your pump is working, these pump inlet screens are used widely in the Water Industry and Agricultural sector and elsewhere where contaminated water needs to be moved.

Uniquely, Rotorflush Filters Limited offer submersible pumps with built-in self-cleaning pump inlet screens. These too are all stainless steel mechanical intakes that continuously backwash the inlet screen mesh whenever the pump is working, reducing maintenance intervals to several months even in challenging raw water conditions.

All Rotorflush Self-cleaning pump inlet screen products can be scaled to meet current EA and EPA requirements for eel and fish screening.

This website uses cookies to ensure you get the best experience. Learn more