Sapphire 400 Filterpumps™

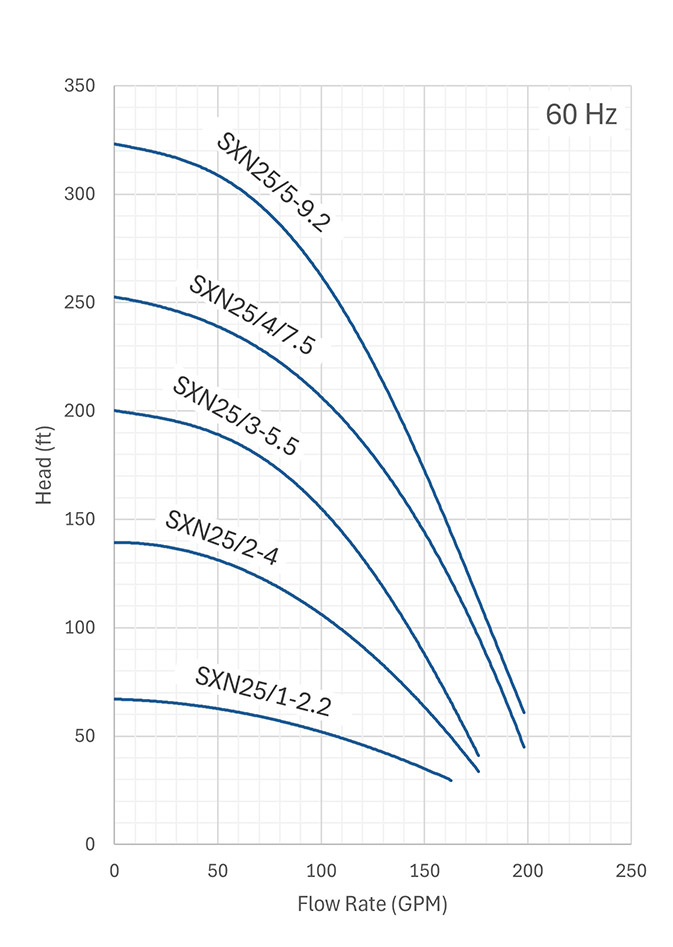

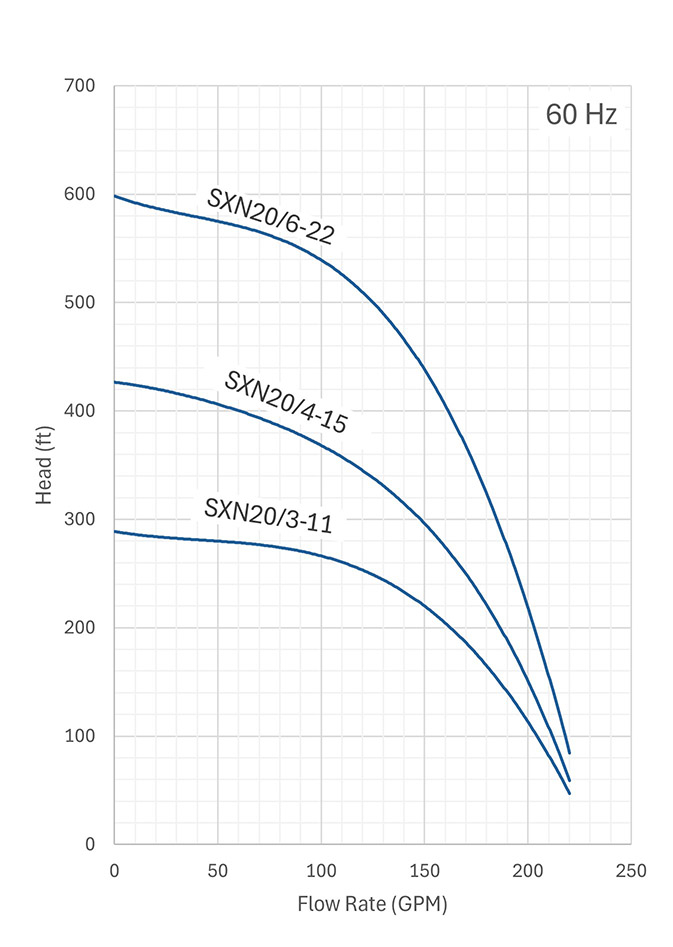

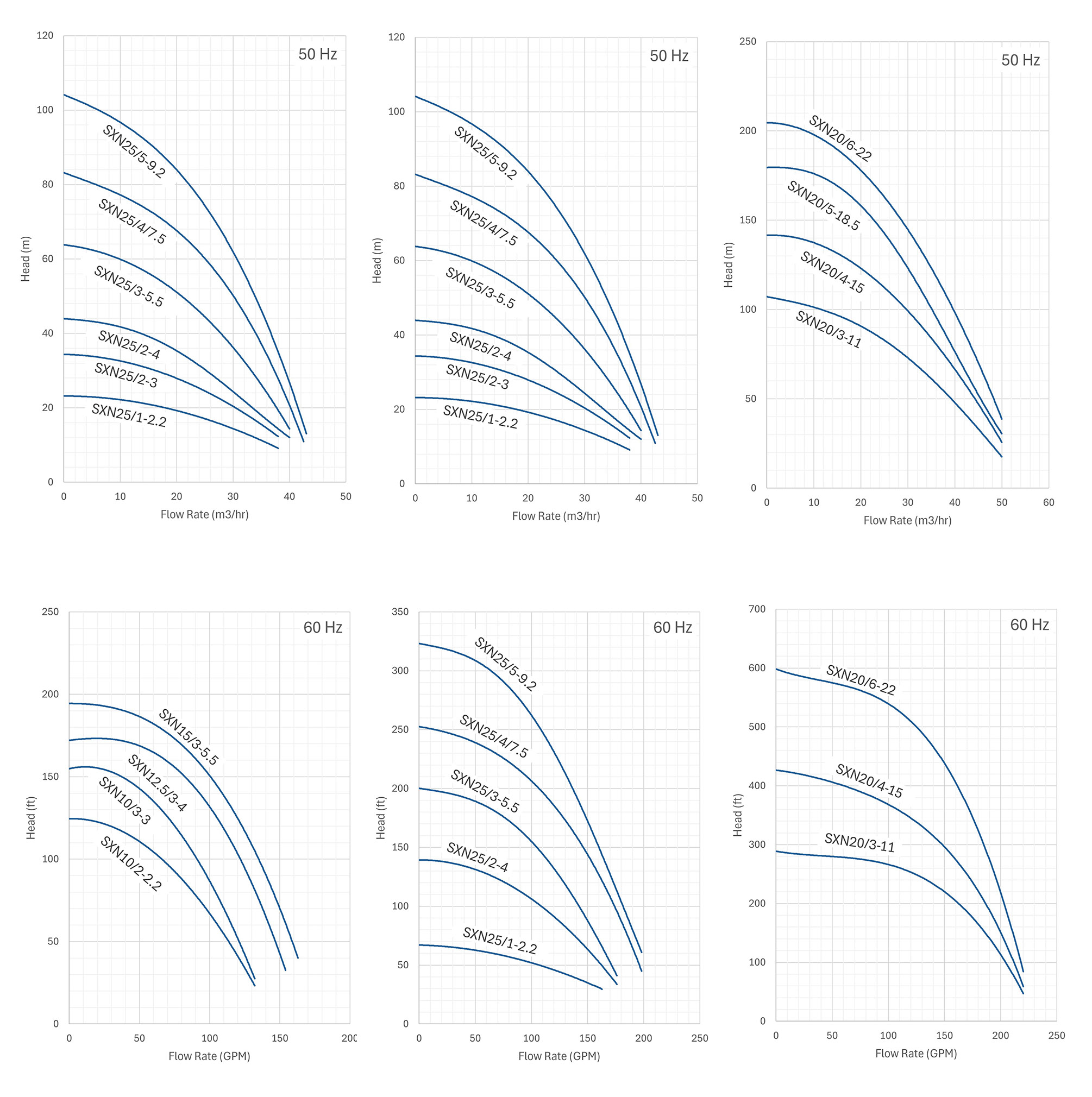

Rotorflush Sapphire Filterpumps™ are general purpose high pressure submersible filter pumps with a built-in self-cleaning suction intake screen. Pump and screen up to 50 m3/h, 220 US GPM, and to a maximum head of 20 bar, 290 psi.

Key Features

Sapphire 400 Filterpumps™

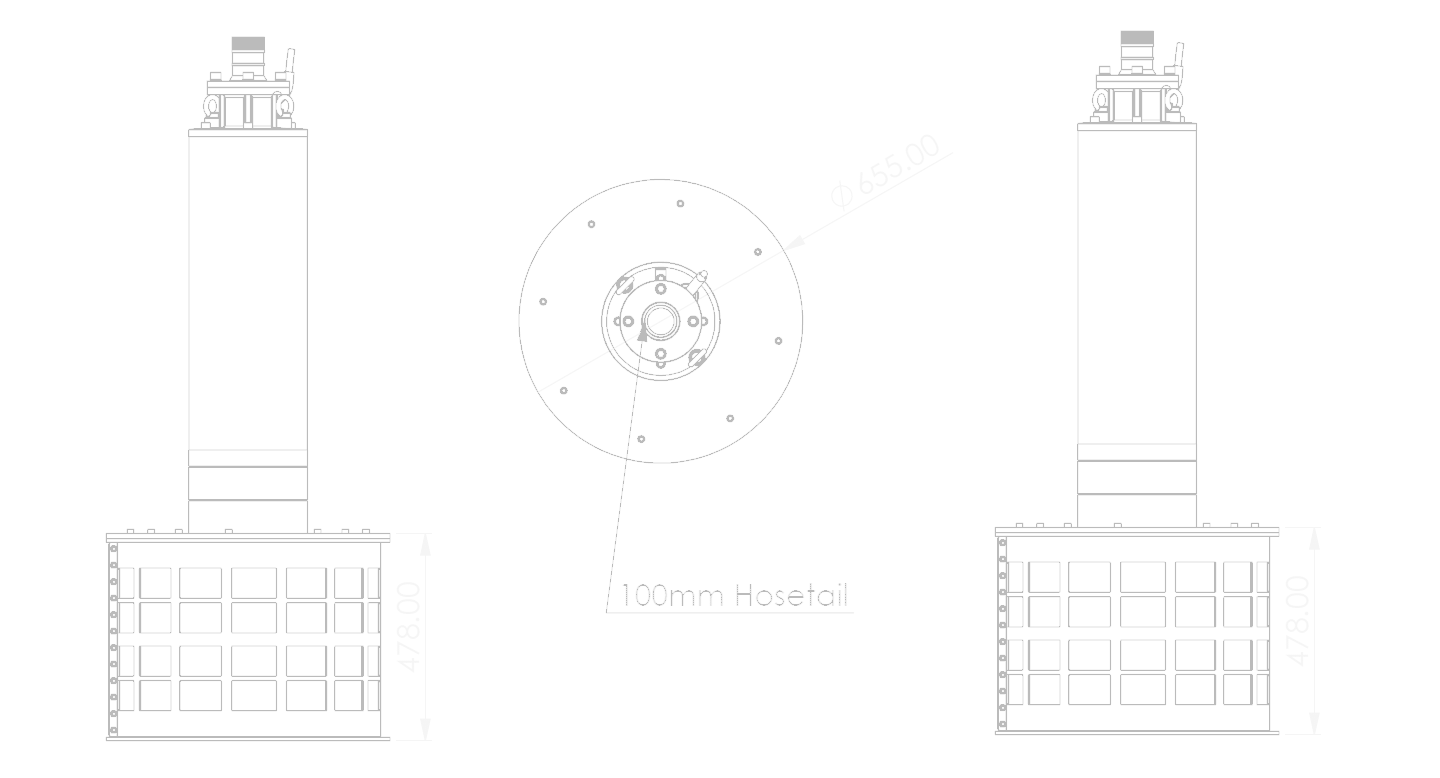

Specifications & Dimensions

Specification

Dimensions

Prices & ordering

- All Models

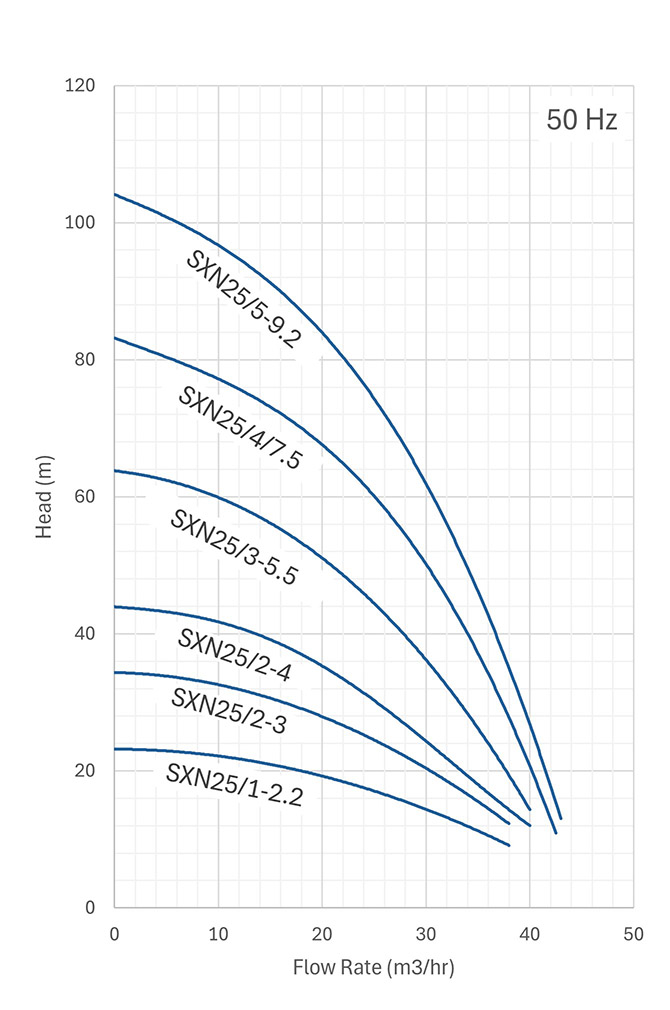

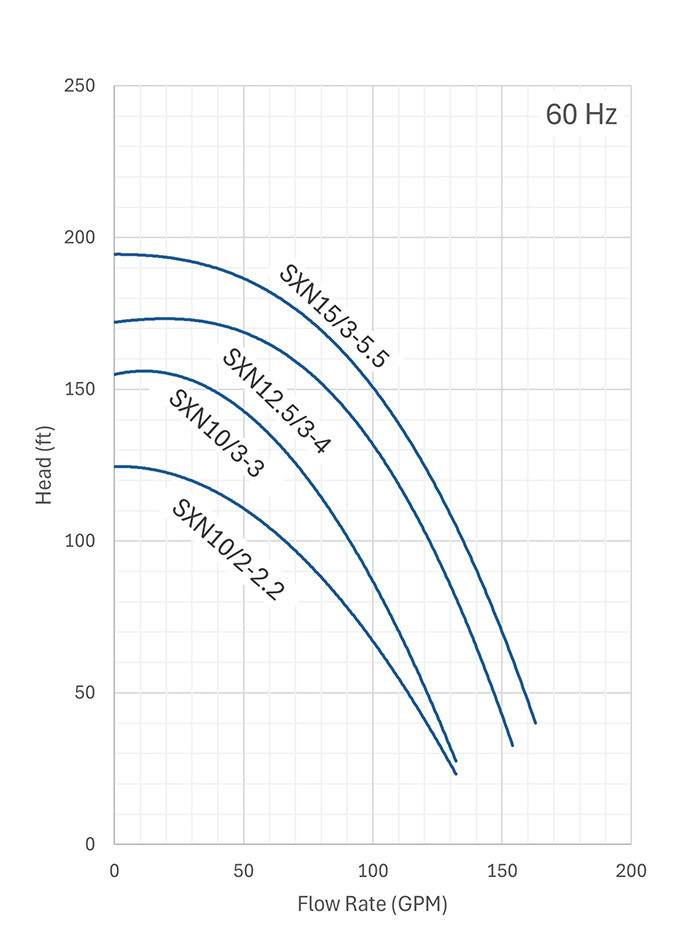

- SXN10/2-2.2

- SXN25/1-2.2

- SXN10/3-3

- SXN25/2-3

- SXN12.5/3-4

- SXN25/2-4

- SXN15/3-5.5

- SXN25/3-5.5

- SXN25/4-7.5

- SXN25/5-9.2

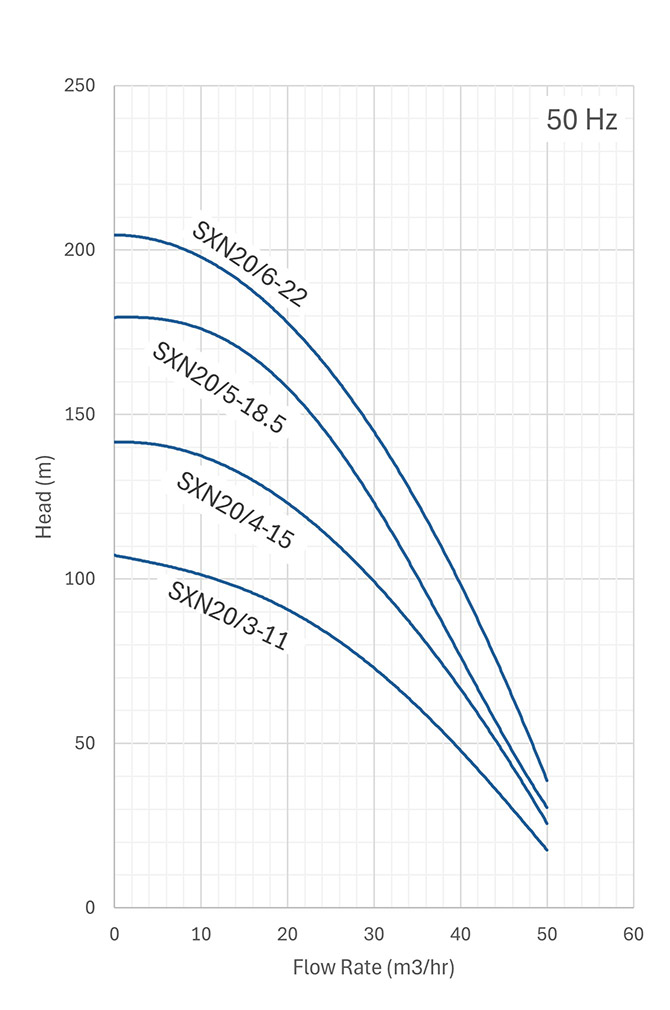

- SXN20/3-11

- SXN20/4-15

- SXN20/5-18.5

- SXN20/6-22

Similar Products

Nauti Filterpumps™

Rotorflush Nauti Filterpumps™. High-head submersible filter pumps with built-in self-cleaning filters on the suction intake. They have a maximum output of 220 litres a minute, and can pump up to 10 bar. Pumping and filtration are combined. All stainless steel construction.

- Maximum Output 220 L/Min

- Maximum Head 103 m

Price from: £2,915

RUBI 400 Filterpumps™

Industrial Submersible Water Pumps with a Built-in Self-cleaning Suction Intake Screen. RUBI Filterpumps™ are extremely tough filter pumps, suitable for heavy industrial applications. They will pump and screen up to 1000 litres a minute, 528 US GPM, and have a maximum head of 10.2 bar, 145 psi.

- Maximum output - 60 m3 / hr

- Maximum head - 102 m

Price from: £11,780

Sapphire 600 Filterpumps™

Industrial Submersible Water Pumps with a Built-in Self-cleaning Suction Intake Screen. Rotorflush Sapphire Filterpumps™ are general purpose high pressure submersible filter pumps with a built-in self-cleaning suction intake screen. Pump and screen up to 90 m3/hr, 400 US GPM, and to a maximum head of 14 bar, 200 psi.

- Maximum output - 90 m3/hr, 400 US GPM

- Maximum head - 14 m, 460 ft

Price from: £19,020

General Information about Sapphire 400 Filterpumps™

Our Sapphire Filterpumps™ are high pressure multi-stage submersible filter pumps with a built-in self-cleaning suction intake. This allows high-pressure, low-maintenance pumping in difficult water conditions. Durable and robust, these filter pumps are cast iron and stainless steel construction.

These filter pumps provide high head flow rates from up to 50 m3/hr, 220 US GPM. The powerful three-phase motors have thermal overload protection, and the intake screens are available in a range of mesh sizes.

Typical uses for Sapphire Filterpumps™ are:

- Wash water for wastewater trash screens

- Wash water for raw water intake screens

- Irrigation

- District and other heat pump systems

- Anywhere you need high pressure screened water.

Sapphire Filterpumps™ ready to meet their customer.

316 Sintered Stainless Steel Mesh

Robust screen material that can be easily cleaned with a pressure washer. Ideal for heat pumps and other applications where small tolerances require finer screening.

Available in 100 and 315 micron apertures.

316 Stainless Steel Woven Mesh

A tough screen providing for low maintenance; filter pumps with coarse mesh come fitted with rubber backwash jets which are suitable for handling larger particulate and debris.

Available in 1 mm, 2 mm and 3 mm. 2 mm aperture mesh recommended for Fish and Eel protection

316 Stainless Perforated Mesh

Ultra-tough, low-maintenance perforated stainless steel screens. Filter pumps with perforated mesh come fitted with rubber backwash jets, which are suitable for handling larger particulate and debris.

Perforated steel in 3 mm, 6 mm and 10 mm apertures.

These filter pumps are ideal for screening and pumping quarry run-off, industrial process water, raw water, seawater and general heavy industrial uses.

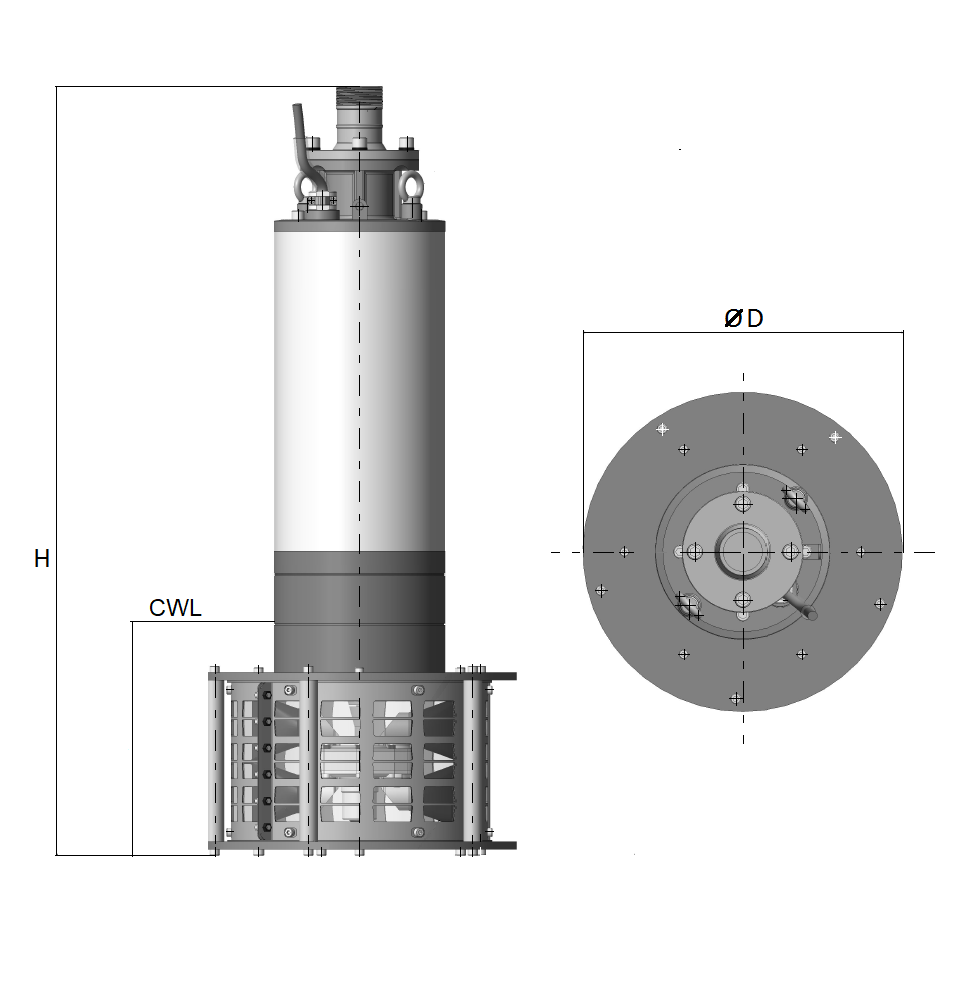

The filter pumps have a weight range from 84 kg - 313 kg, lifting gear is required to move them. These filter pumps can be suspended in tanks, sumps or ponds or from buoys, or raised and lowered on a guide-rail system.

For best performance, make sure that there is good clearance around the filter pump mesh so that back-washed debris can disperse, and that the filter pump is above any silt or sludge that may accumulate.

There is no such thing as an entirely maintenance free filter, but Sapphire Filterpumps™, in keeping with all Rotorflush filtration products, are designed for low maintenance hassle-free use. Easy to pressure wash stainless steel mesh and in-built thermal protection in the filter pumps ensures smooth running.

The stainless mesh should be cleaned with a pressure washer. There is a trade-off between mesh size and maintenance - how often depends on your mesh size and the quality of what you are filtering.

As a minimum we recommend the following:

- 100 micron mesh should be cleaned every 1000 hours of use

- 315 micron mesh should be cleaned every 5000 hours of use

- Coarse mesh that is 1 mm or bigger should be inspected and cleaned every 6 - 12 months

As a condition of our guarantee, and to protect against dry-running, we recommend the use of a starter panel or control panel capable of cos phi load monitoring when running these filter pumps.

Full maintenance guidelines can be found in the instruction manual available from the download link above.

What is the difference between a Rotorflush Filterpump™ and a filter pump?

A filter pump is a pump with a filter on the intake; a Rotorflush Filterpump™ is our unique, award-winning submersible pump with a built-in self-cleaning filter on the pump intake that keeps the intake filter clear and protects the pump from blocking and clogging.

Why Rotorflush?

Designed & Manufactured in the UK

All our products are built to order and can be made to customer specifications.

- Built to meet your required flow rate

- Filter down to 50 microns

- High quality filtration products hand built in the UK

Rotorflush are Experts in Pumping and Screening Water

Our products and expertise have been appreciated by satisfied customers for over 2 decades.

- Industry experts for over 20 years

- 1000's of products successfully deployed worldwide

- Rotorflush products can screen from 2 - 1085 m3/hour

- Keeping water flowing, and pumps, screens, spray bars and other equipment working

Worldwide delivery and service

Through our worldwide distribution network, we offer the ability to:

- Deliver filter pumps worldwide almost anywhere

- Help service your filter pump

- Repair a broken filter pump (whatever you've done to it…)

Contact us to find out more...

Call us now on 01297 560 229 | 8am - 5pm GMT,

or Email sales@rotorflush.com and a member of our expert, friendly team will call you back and will find the filter pump for your needs.

- We work with you to identify your issues

- We can design & build a custom solution

- We can deliver our solution worldwide

Find the Sapphire Filterpump™ that meets your requirements..

Tell us which Sapphire Filterpumps™ you'd like to know more about, or tell us your choice of Sapphire...

This website uses cookies to ensure you get the best experience. Learn more