RF1000LW Self-cleaning Intake Strainers and Eel Screens

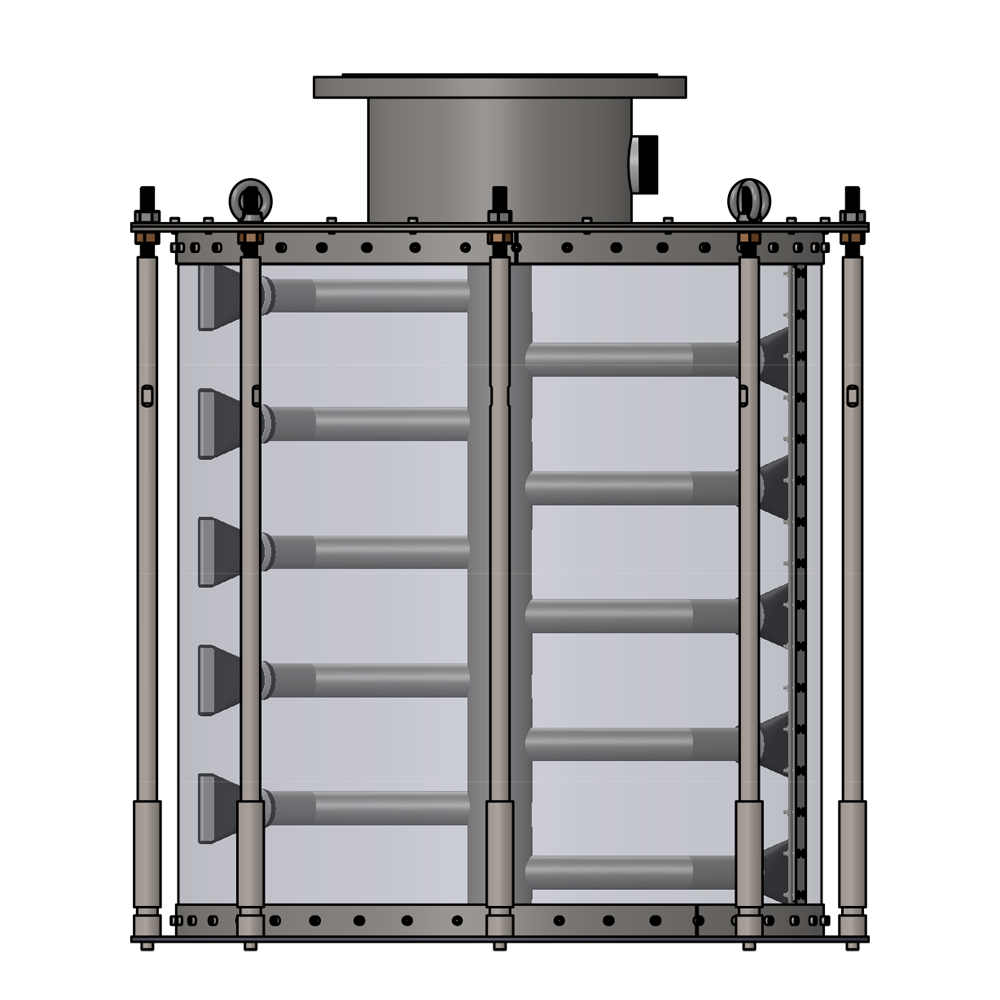

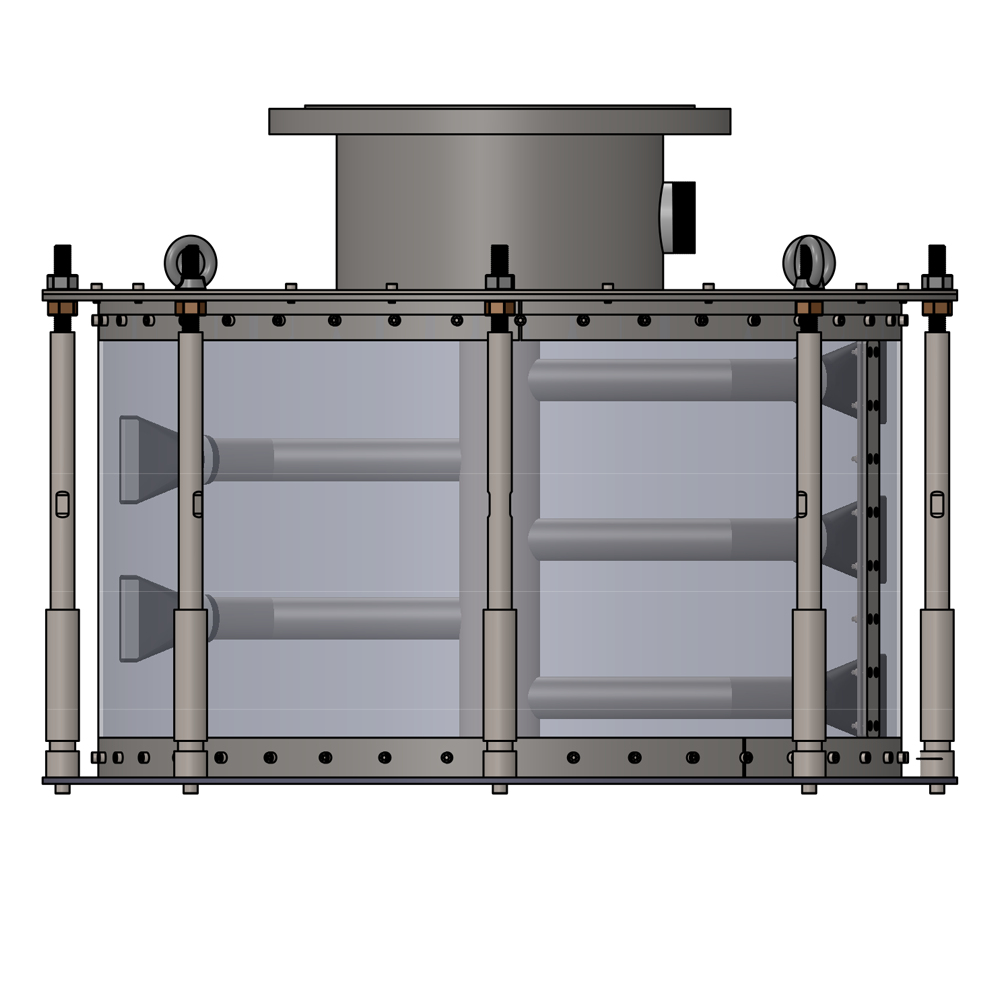

Self-cleaning Industrial Water Filters & Strainers. RF1000LW Suction Intake Strainers and Eel Screens, 1000 mm in diameter, for use in raw and contaminated water. Industrial strength, low maintenance, all stainless steel self-cleaning basket strainers to prevent blocking and blinding during water abstraction. These intake screens handle up to 1,357 m3 / hour, 5,975 US GPM (when fitted with 2 mm mesh).

Key Features

RF1000LW Self-cleaning Intake Strainers and Eel Screens

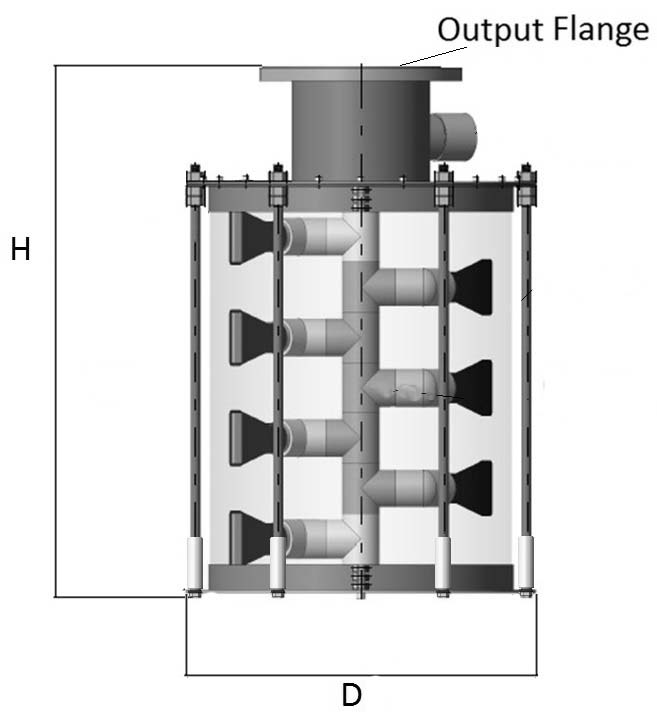

Specifications & Dimensions

Specification

Dimensions

Prices & ordering

- All Models

- RF1000-200LW

- RF1000-300LW

- RF1000-400LW

- RF1000-500LW

- RF1000-600LW

- RF1000-700LW

- RF1000-800LW

- RF1000-900LW

- RF1000-1000LW

Downloads

Similar Products

RF800LW Self-cleaning Strainers and Eel Screens

Self-cleaning Industrial Water Strainers and Eel Screens. Our RF800LW industrial strength, low maintenance, stainless steel self-cleaning basket strainers protect equipment from blocking and blinding when pumping dirty water. These suction side screens handle up to 1085m3/hour, 4,775 US GPM.

- Screen up to 1085 m3 / hour, 4775 US GPM

- Filter from 6 mm down to 1 mm

- US Mesh 3 down to 18

- Ideal for Fish and Eel Screening

Price from: £10,980

RF1100LW Self-cleaning Strainers and Eel Screens

RF1100LW Self-cleaning Strainers and Eel Screens. Our largest standard RF1100LW industrial, stainless steel, self-cleaning strainers (larger bespoke sizes can be made to order). These low maintenance suction side intake screens will handle up to 1642 m3/hour, 7230 US GPM when fitted with 2 mm aperture mesh.

- Screen up to 1642 m3 / hour, 7230 US GPM

- Filter from 6 mm down to 1 mm

- US Mesh 3 down to 18

- Ideal for Fish and Eel Screening

Price from: £0

RF1000AR Self-cleaning Strainer

RF1000AR Self-cleaning Industrial Water Filters and Strainers. 1000 mm diameter self-cleaning intake strainers for attachment to the suction hose of surface mounted pumps. These tough industrial all stainless-steel construction mechanical filters can deliver up to 1,045 m3/hour, 4,600 US GPM

- Screen up to 1045 m3 / hour, 4600 US GPM

- Filter from 6 mm down to 1 mm

- US Mesh equivalent 3 down to 18

Price from: £0

General Information about RF1000LW Self-cleaning Basket Strainers

Self-cleaning Industrial Water Filters and Strainers used for pumping dirty or contaminated water.

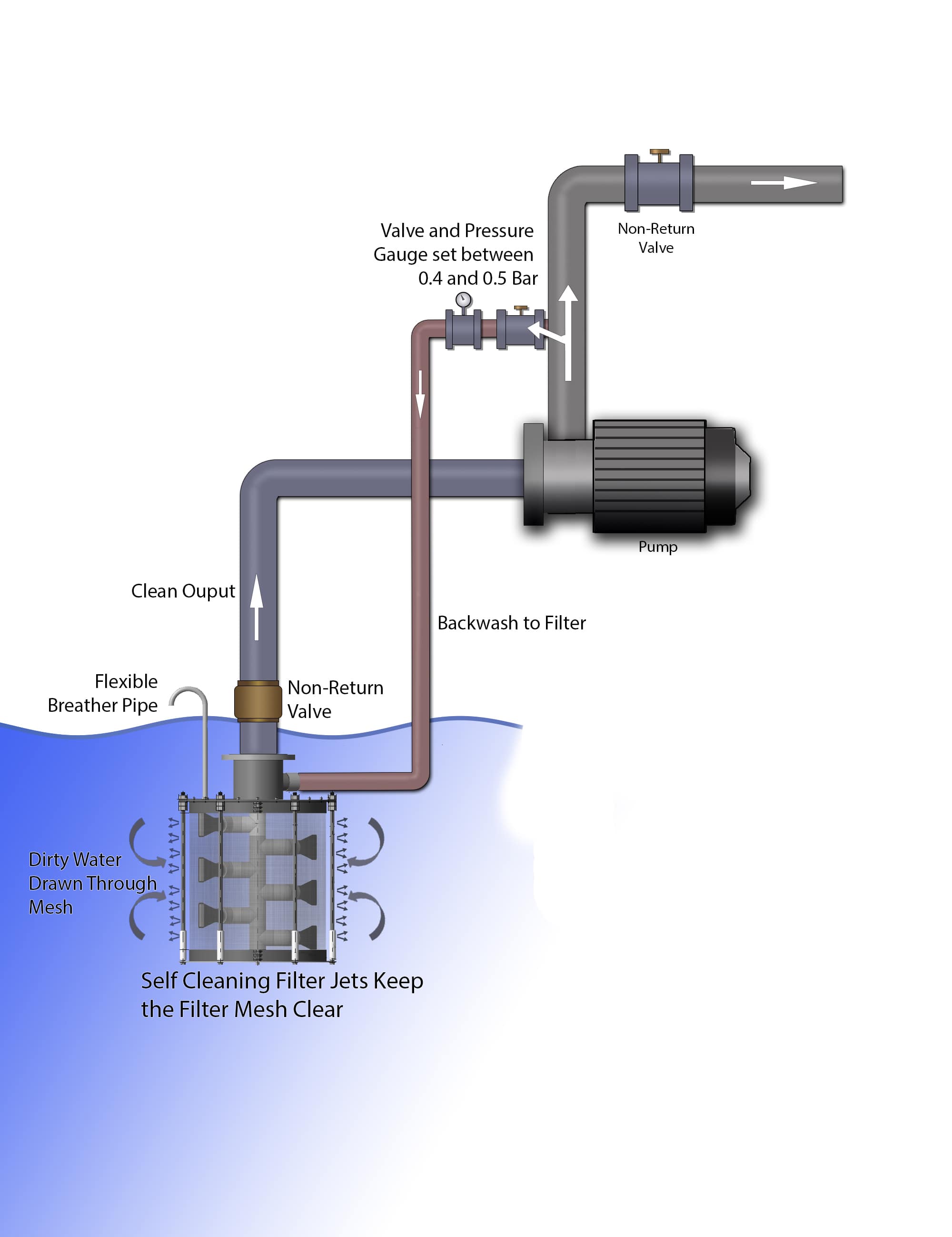

RF1000LW filters are general purpose suction intake basket strainers with a built-in self-cleaning mechanism that back-washes their mesh as water flows through the screen. They are all stainless steel, high volume screens developed specifically to meet the challenges of EPA and Environment Agency regulations for raw water abstraction. Ideal for Eel screening and Fish protection.

The designation ‘RF1000’ indicates that the filter mesh is 1000 mm in diameter. Water is screened as it is drawn through the filter mesh, helping to prevent the intake, pump and any connected equipment from blocking.

These self-cleaning intake filters attach to the suction of surface mounted pumps, or can be used to screen water flowing by gravity. Here are some typical uses of these intake screens:

- Irrigation and livestock watering

- Cooling water screening for EPA Rule 316 (b) and Eel Regulations compliance

- Screening industrial process water

- Screening water when draining / flooding wetlands

- Protecting district wide heat pump installations

- Screening for desalination plant intakes

Trial LW Self-cleaning Intake for Eel Screening

Self-cleaning water intake screens - ‘AR’ type screens or ‘LW’ type screens?

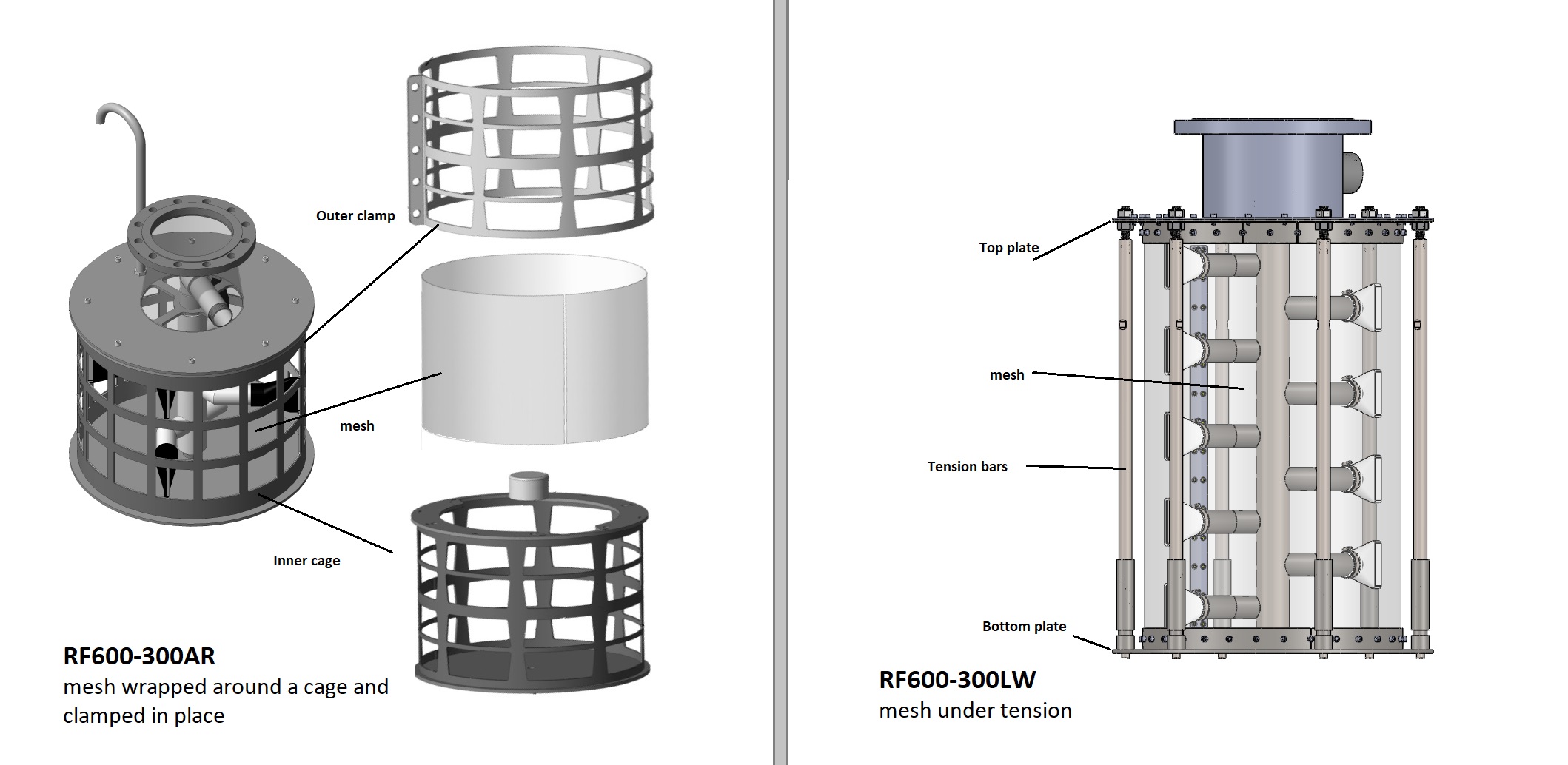

The difference between a self-cleaning intake screen or filter designated AR, and a self-cleaning intake screen or filter designated LW is in their construction.

‘AR' type strainers and filters are made with a cage frame around which filter mesh is wrapped. This is held in place by a clamp. The filters are easily identifiable as ’AR' type as filter mesh area comprises a series of mesh windows.

‘LW’ type strainers and filters do not have a cage body; the mesh is the filter body. The filter mesh is tensioned between the filter top and bottom plates, and is tight - like a drum skin. This gives the mesh structural integrity and strength. ‘LW’ filters are easily identifiable as the body is all mesh.

What's the diff?

AR filters up to 600 mm diameter can be fitted with mesh down to 315 microns. The ‘AR’ type self-cleaning filters and strainers are very strong - the body being made up of a cage and a clamp - two layers of steel - and are suitable where conditions are challenging such as turbulent river or seawater locations.

The downside is that they handle less water for the size of screen, because the open area of the mesh is reduced by the cage and clamp.

LW filters can only be fitted with mesh of 1 mm or greater aperture. This is because the mesh needs to be robust enough to tension. The ‘LW’ type self-cleaning filters and strainers are also strong - but are more suited to applications and settings where low intake velocities are required - for example for fish or eel screening at cooling water and raw water intakes.

The on the plus side they handle more water than the ‘AR’ type filters for the same size of screen, because the open area of the mesh is maximised; the mesh is area is not reduced by a supporting cage or clamp.

'AR' type self-cleaning strainers and filters compared with 'LW' type self-cleaning strainers and filters

Rotorflush RF1000LW self-cleaning suction intakes can be fitted with:

316 grade Stainless Steel Woven Mesh

A coarse woven mesh screen providing low maintenance cycles, filters and screens with coarse mesh come fitted with rubber backwash jets which are suitable for handling larger particles. Ideal difficult water conditions.

Mesh apertures available: 1 mm, 2 mm, 3 mm and 5 mm mesh or contact us if you have a particular requirement.

RF1000LW self-cleaning basket strainers are ideal for screening and pumping raw water, cooling water, and seawater, particularly where there is a need to protect aquatic life. Their high volume, low-velocity intake easily complies with EPA and Environment Agency rules.

The strainers have a dry weight range from approx. 155kg - 275 kg depending on model and outlet flange size, lifting gear is required to move them. RF1000LWs can be suspended in lakes, lagoons or rivers, or floated from buoys, or raised and lowered on a guide-rail system. They can often be bolted directly on to the intake of vertical and immersible pumps.

For best performance, make sure that there is good clearance around the strainer mesh so that back-washed debris can disperse, and that the RF1000LW is above any silt or sludge that may accumulate.

We also manufacture stands and guide rails specifically designed for our products to help you to site and maintain them.

Usually very little. Although they are self-cleaning, all of our products will require a manual clean every once in a while.

Stainless mesh can be cleaned with a pressure washer. How often depends on your mesh size and what you are filtering.

As a minimum, we recommend the following:

- Coarse mesh that is 1 mm or bigger should be inspected and cleaned every 6 – 12 months

Full maintenance guidelines can be found in the instruction manual available from the download link above.

All our products are guaranteed for at least a year. Full details in our Terms and Conditions.

Why Rotorflush?

Designed & Manufactured in the UK

All our products are made to order, and many can be made to customer specifications.

- Built to meet your requirements

- Screen dirty water down to 1 mm

- Made to order in the UK

- All stainless steel construction

Experts in Water Screening and Filtration

Our products and expertise have been appreciated by satisfied customers for over 2 decades.

- Industry experts for over 20 years

- 1000's of products in use worldwide

- Successfully screening 10 - 7,225 US GPM / 2 - 1,640 m3 hr

- Our products keep water flowing by protecting pumps, screens, spray bars…….

- .…nozzles, heat exchangers and other connected equipment from blocking

Worldwide delivery and service

Through our worldwide distribution network, we offer the ability to:

- Deliver filters and strainers worldwide

- Help service your filter or strainer

- Repair a broken filter or strainer (whatever you've done to it…)

Speak to one our knowledgeable staff...

Call us now on 01297 560 229 | 8am - 5pm GMT,

or Email sales@rotorflush.com and a member of our expert, friendly team will call you back and find the filter or strainer for your needs.

- We work with you to identify your issues

- We can design & build a custom solution

- We can deliver our solution worldwide

We'll help you find the right RF1000LW for you

or tell us which RF1000LW filter you'd like to know more about.

This website uses cookies to ensure you get the best experience. Learn more