What is the Filter mesh on Self-cleaning Intakes?

Filter Mesh for Pump Suction Intake Hoses

Mesh filters for pump intakes are available in a range of sizes and materials.

At the lower end of the market, plastic filter mesh, and at the higher and stainless-steel mesh. The biggest difference is that more robust steel filter meshes can be properly pressure washed without fear of damaging the mesh filter.

Care has to be taken with plastic or nylon mesh filters. Plastic filter mesh will need more frequent replacement than metal and steel mesh.

Blocked Filter Mesh?

As anyone who has ever had to deal with a blocked pump intake knows,

Mesh filters and mesh screens can clog and blind very easily. Environmental regulations to protect fish and eel stocks are making the use of mesh filters and screens more necessary, often requiring 2 mm aperture (US 10 Mesh) or below.

Fat chance of a hassle-free day when pumping out from that muddy weed ridden pond, lake or stream….unless you are using a self-cleaning mesh filter with a backwash to keep the screen from blinding.

Self-cleaning Filter Mesh?

Yes, Self-cleaning Filter Mesh!

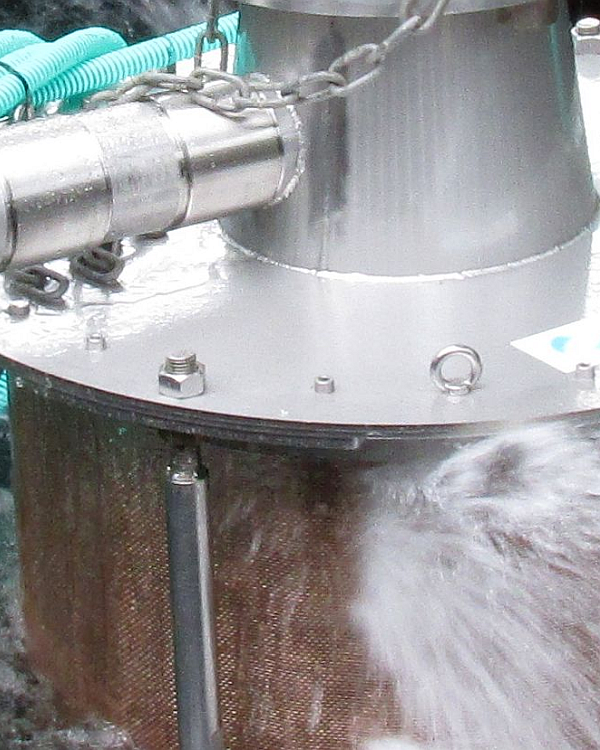

Rotorflush filters limited manufacture and sell a wide range of self-cleaning filters that connect to the suction intake of pumps. We also manufacture and sell submersible pumps with a built-in self-cleaning intake system. Smaller products will take a nylon filter mesh, larger products need the more robust stainless steel meshes we offer.

We sell spare nylon and spare stainless steel filter mesh for our mesh filter filtration products.

The best mesh for our self-cleaning filters is either a bias cut strong woven nylon filter mesh, a sintered 316 grade stainless steel mesh for fine filtration or a woven 316 grade stainless steel filter mesh for coarser use.

Find out more or contact us today!

Find out much more information about filter mesh, filters and self-cleaning filters for use in dirty or contaminated water.

For more information about how Rotorflush filtration products fitted with stainless steel or nylon filter mesh on their unique and patented self-cleaning intake filters can protect help stop your filter mesh from blocking.