Lake Water Pumps and Filters

Pumping and filtering lake water for various uses, such as industrial processing, heat exchange, irrigation or drinking, involves a systematic approach to ensure the water is safe, clean and fit for purpose.

Given that lake water may contain pollutants, sediments, and will contain organic debris (leaves, weed etc), microorganisms and aquatic life, it requires careful treatment before use.

This typically includes several key steps: sourcing the water, removing particulate, secondary and possibly tertiary filtration and sanitisation for drinking water.

Things to Think About

Can the water be used for the purpose in mind?

Understanding the quality of the water to be used is necessary to assess its suitability. You may need to be aware of pH, turbidity, dissolved oxygen levels, and the presence of contaminants or pathogens.

Also, availability may vary seasonally - the depth & distance from shore may vary considerably over a year, affecting the quantity that can be drawn sustainably and the distance and head that needs to be pumped.

Permissions

In many jurisdictions, abstracting water from natural sources like lakes requires obtaining permits or licences from relevant authorities. These regulations are designed to manage water resources sustainably and protect aquatic ecosystems.

Often these permissions will stipulate when water can be drawn and maximum abstraction rates. There may be constraints on pumping and screening equipment to ensure the protection of wildlife.

Compliance with local laws ensures that abstraction does not exceed allowable limits and considers other users’ needs (e.g., recreational activities, wildlife).

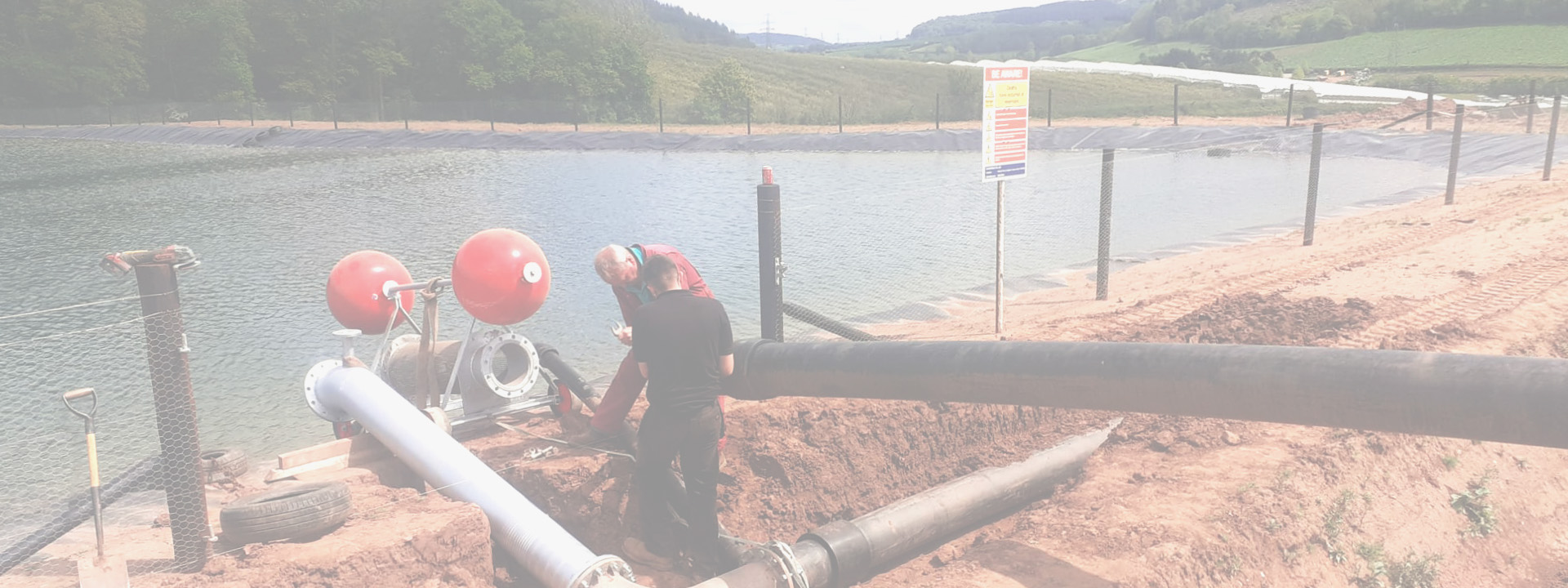

Infrastructure

It's important to match infrastructure and equipment to the requirement for water. Pipework needs to be commensurate with distance to be pumped. Pumps and screens need to be adequate for the flow rate and head.

The location of pumping and screening equipment needs to account for security and ease of maintenance while minimizing environmental impact while ensuring efficient water transport.

Screening and Filtering Lake Water

Why screen lake water?

Screening is a vital step in preparing lake water for use. It involves removing larger debris (such as leaves, weed, heavier grit and sand) that could damage equipment or contaminate the water supply.

How fine should screen mesh be?

This will depend on water quality, the volume of water being pumped and what happens to the pumped water next.

The finer the mesh the more often it needs maintaining. So be guided by the equipment the water is going to. If water is being pumped to a heat exchanger and then back to the lake then the mesh size should be a fifth to a third of the minimum aperture size through the heat exchange system.

If the water is for consumption there may be secondary and tertiary filters to ensure drinking water quality. Removing debris above 0.5 – 0.1 mm will extend the life of subsequent filters.

Is there a way of keeping screens and filters clear while pumping from the lake?

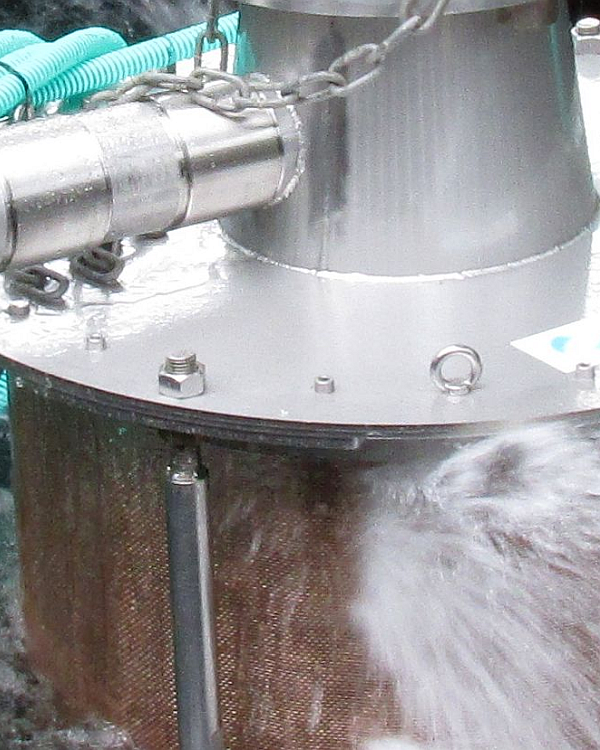

Yes there is – have a look at Rotorflush’s Self-cleaning Suction Intake Filters and submersible Filterpumps (see pic) - submersible pumps with self-cleaning intake screens.

Self-cleaning Suction Intakes

Rotorflush's robust and reliable self-cleaning intake strainers and submersible filterpumps filter debris and particulate from lake water. At the same time they keep their filter screens clear and clean with a continuous automatic backwash system. A self-cleaning pump filter ends the worry of a constantly blocking filter or pump.

In addition, valuable equipment – heat exchangers, water features, irrigation equipment, fountains etc – are protected from blocking. At the least this saves on downtime and maintenance, and at best protects against loss of expensive machinery.

Unlike traditional basket strainers Rotorflush self-cleaning pump filters and intake strainers protect against blinding and clogging. Pumping and screening are combined - our self-cleaning intake filters help ensure a continuous filtered supply from your pump in very dirty water conditions. All our filters are truly – and continuously – self-cleaning.

Next Steps

After initial screening, further treatment may be necessary depending on the intended use of the water:

Further filtration ensures that any remaining impurities are removed before consumption or use in irrigation systems. For drinking purposes specifically, reverse osmosis (RO) systems are highly effective at removing chemical contaminants that might have entered through industrial run-off or recreational activities on the lake. For general usage like irrigation, a combination of backwashing filters for heavy sediment removal and UV light for sanitization should suffice.

Continuous monitoring of both the abstracted water quality and the ecological health of the lake is essential post-abstraction. Adaptive management strategies should be employed to adjust abstraction practices based on monitoring results.

By following these steps diligently, lake water can be effectively abstracted and screened for various uses while minimizing negative impacts on both human health and aquatic ecosystems.

Find out more or contact us today!

Get in touch to find out more about how Rotorflush self-cleaning filtration products can benefit your lake water use and management.

Contact the Rotorflush team for a discussion with our knowledgeable and friendly staff.

This website uses cookies to ensure you get the best experience. Learn more