Learn More

Industrial Processes

Rotorflush products are used for screening and pumping process and waste water in many industries including, paper-mills, quarries, desalination plants, distillers, power stations, food manufacturers, Heathrow Airport - and many more.

The cost of water, water treatment and monitoring, and waste water disposal can have a significant impact on production costs. Considerable savings can be made by re-using and recycling water, and more efficiently treating waste water.

Rotorflush self-cleaning filter pumps and strainers provide a low maintenance means of pumping and filtering water. Our products are particularly useful for removing debris and solids in suspension.

Browse Products

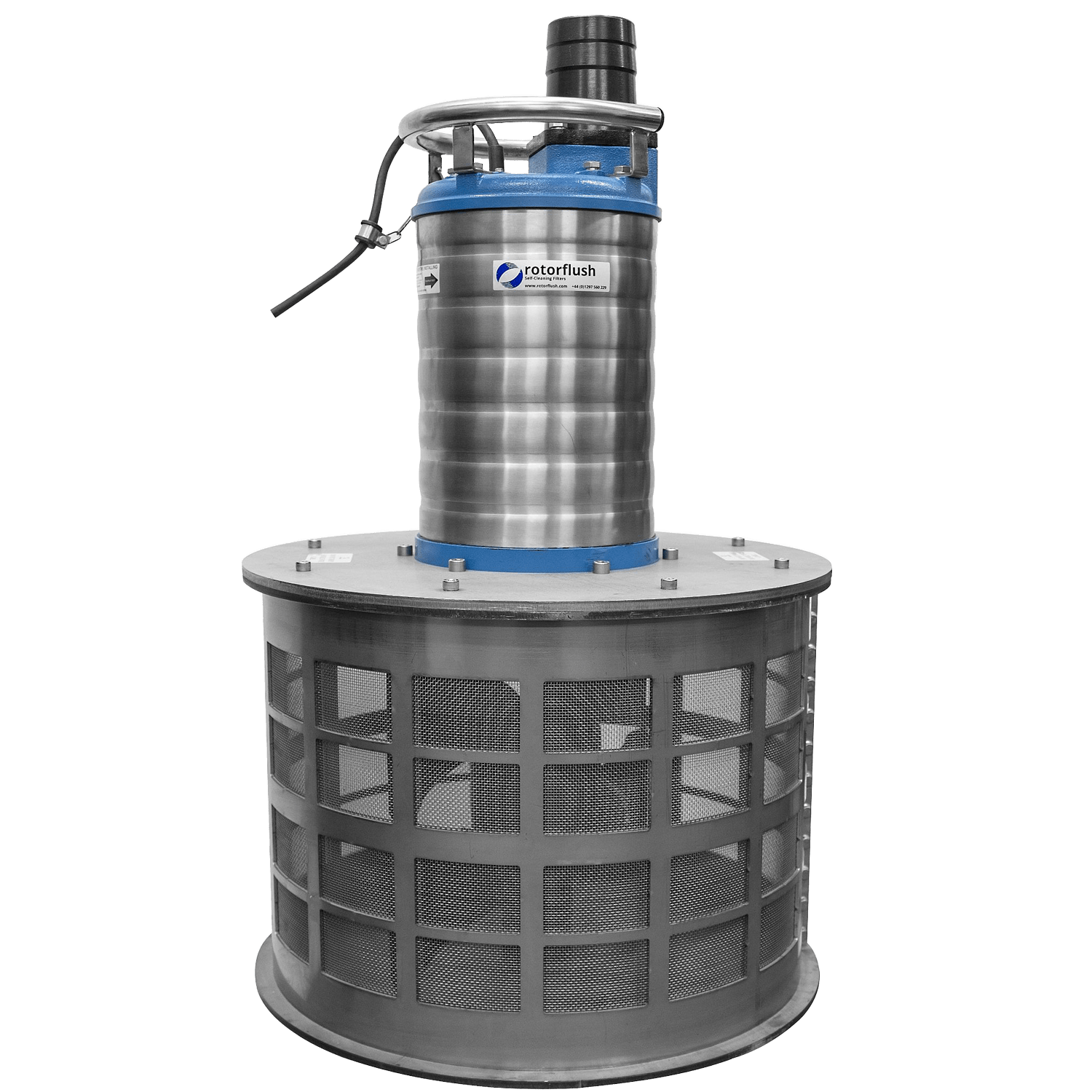

Opal SH400 Filterpumps™

Industrial Submersible Water Pumps with a Built-in Self-cleaning Suction Intake Screen. Opal SH400 Filterpumps™ are very tough, hard cast iron filter pumps, suitable for heavy industrial applications. They have built thermal protection built-in to the hermetically sealed motor. They will pump and screen up to 1000 litres a minute, 265 US GPM, and have a maximum head of 7.7 bar, 112 psi.

- Maximum output - 60 m3 / hr

- Maximum head - 77 m

Price from: £0

RUBI 400 Filterpumps™

Industrial Submersible Water Pumps with a Built-in Self-cleaning Suction Intake Screen. RUBI Filterpumps™ are extremely tough filter pumps, suitable for heavy industrial applications. They will pump and screen up to 1000 litres a minute, 528 US GPM, and have a maximum head of 10.2 bar, 145 psi.

- Maximum output - 60 m3 / hr

- Maximum head - 102 m

Price from: £11,780

Sapphire 400 Filterpumps™

Rotorflush Sapphire Filterpumps™ are general purpose high pressure submersible filter pumps with a built-in self-cleaning suction intake screen. Pump and screen up to 50 m3/h, 220 US GPM, and to a maximum head of 20 bar, 290 psi.

- Maximum output - 50 m3/h, 220 US GPM

- Maximum head - 200 m, 656 ft

Price from: £8,985

RF1000LW Self-cleaning Intake Strainers and Eel Screens

Self-cleaning Industrial Water Filters & Strainers. RF1000LW Suction Intake Strainers and Eel Screens, 1000 mm in diameter, for use in raw and contaminated water. Industrial strength, low maintenance, all stainless steel self-cleaning basket strainers to prevent blocking and blinding during water abstraction. These intake screens handle up to 1,357 m3 / hour, 5,975 US GPM (when fitted with 2 mm mesh).

- Screen up to 1357 m3 / hour, 5975 US GPM

- Filter from 6 mm down to 1 mm

- US Mesh 3 down to 18

- Ideal for Raw Water Intakes

Price from: £0

Topaz 400 Filterpumps™

Rotorflush Topaz Filterpumps™. Medium head general purpose submersible filter pumps with integral self-cleaning suction intakes. They combine pumping and screening, delivering up to 60 m3/hr, 265 US GPM - and to a maximum head of 3.3 bar, 47 psi.

- Maximum output - 60 m3/hr, 265 US GPM

- Maximum head - 33 m, 108 ft

Price from: £8,730

Opal 600 Filterpumps™

Industrial Submersible Water Pumps with a Built-in Self-cleaning Suction Intake Screen used for pumping dirty or contaminated water. Opal 600 Filterpumps™ are extremely tough filter pumps, suitable for heavy industrial applications. They will pump and screen up to 3,166 litres a minute, 836 US GPM, and have a maximum head of 23.2 bar, 335 psi.

- Maximum output -190 m3 / hr

- Maximum head - 232 m

Price from: £0

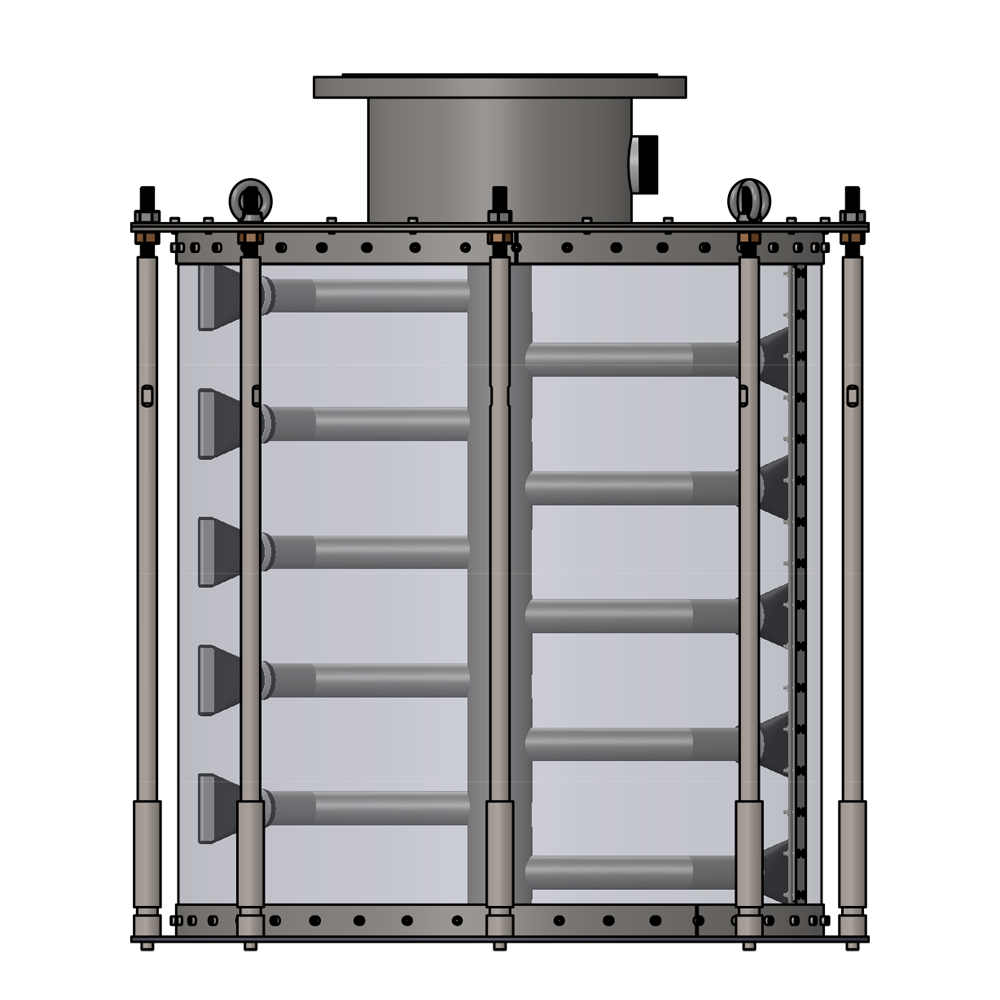

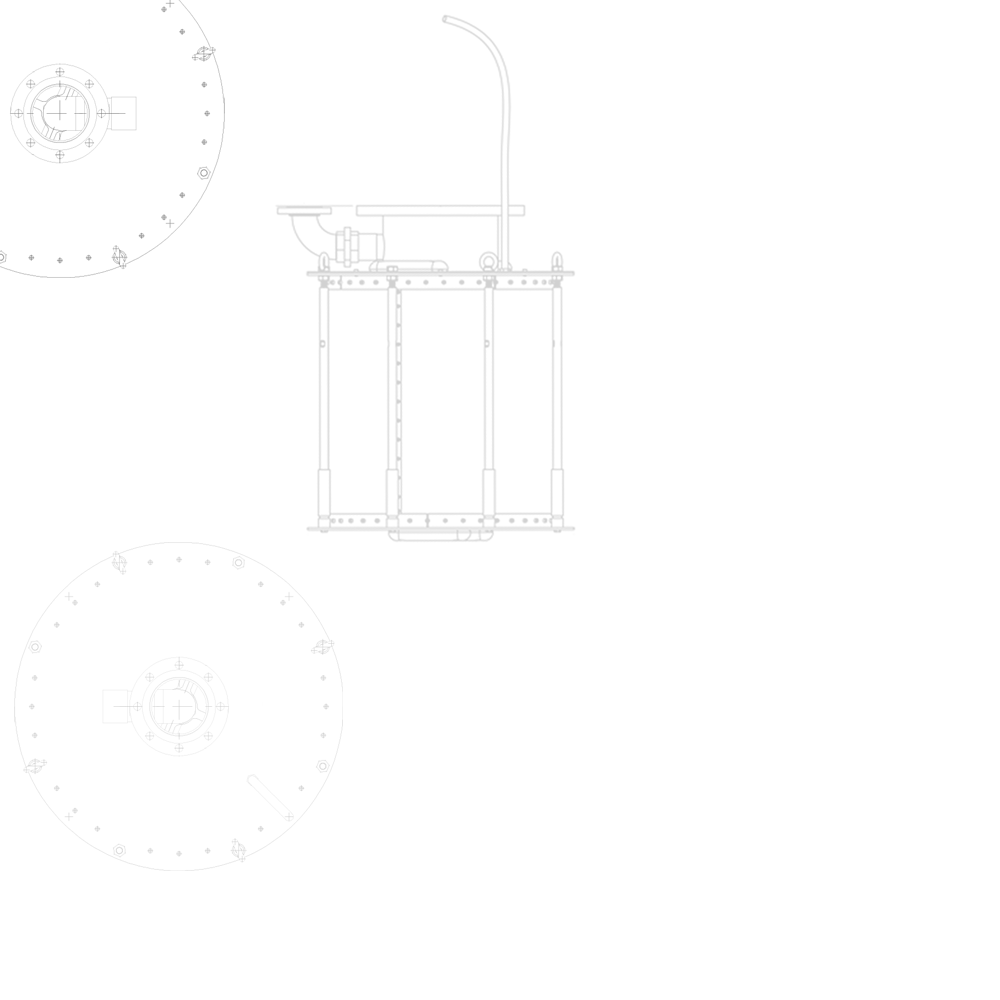

RF1100LW Self-cleaning Strainers and Eel Screens

RF1100LW Self-cleaning Strainers and Eel Screens. Our largest standard RF1100LW industrial, stainless steel, self-cleaning strainers (larger bespoke sizes can be made to order). These low maintenance suction side intake screens will handle up to 1642 m3/hour, 7230 US GPM when fitted with 2 mm aperture mesh.

- Screen up to 1642 m3 / hour, 7230 US GPM

- Filter from 6 mm down to 1 mm

- US Mesh 3 down to 18

- Ideal for Fish and Eel Screening

Price from: £0

Cobalt 600 Filterpumps™

Industrial Submersible Water Pumps with a Built-in Self-cleaning Suction Intake Screen. These Rotorflush Cobalt 600 filter pumps are low to medium pressure, robust filter pumps offering high volume pumping and screening - up to 108 m3 / hr, 475 US GPM.

- Maximum Output - 108 m3 / hr, 475 US GPM

- Maximum Head - 30 m, 98 ft

Price from: £16,090

RUBI 600 Filterpumps™

Industrial Submersible Water Pumps with a Built-in Self-cleaning Suction Intake Screen. RUBI Filterpumps™ are extremely tough filter pumps, suitable for heavy industrial applications. They will pump and screen up to 3000 litres a minute, 795 US GPM, and have a maximum head of 13.8 bar.

- Maximum output - 180 m3 / hr

- Maximum head - 138 m

Price from: £0

Recycle and Re-use

Water Re-cycling and Re-use

Many industrial processes leave water dirty; where the contamination is primarily comprised of solid material in suspension, Rotorflush self-cleaning filters and filter pumps can quickly and efficiently separate particles so that water may be re-used. Here’s a great example from one of our customers:

“We were very happy to recommend Rotorflush’s filterpumps™ for an installation in a glass factory where a re-circulating water spray system is used to cool the molten glass during production. The filter and spray nozzles were daily becoming blocked with particles of glass and scale.

The process environment is extremely hot and hostile, nonetheless we decided to fit a Rotorflush filter to the existing pump and as a result, production now proceeds without interruption.”

Rotorflush self-cleaning filters are being used to remove lint and other debris from wash-water in laundries, allowing for heat recovery, re-use and lower waste water disposal costs.

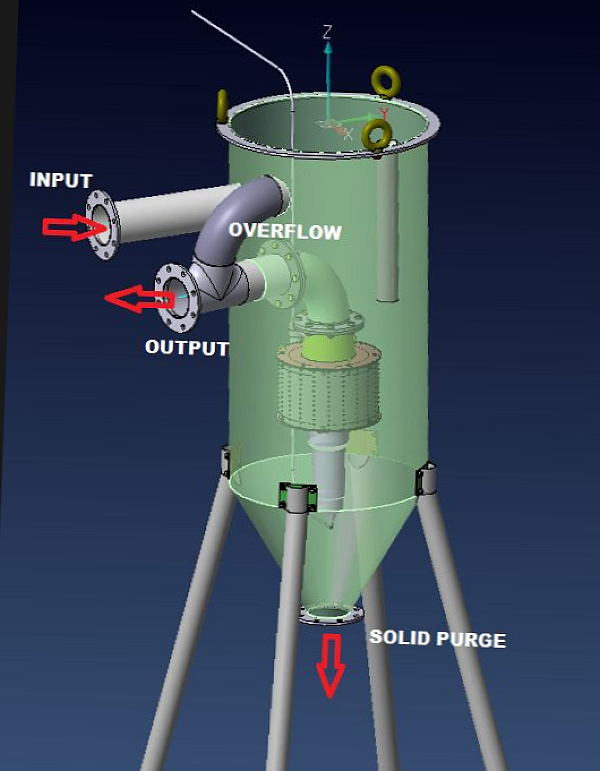

Tank & Sump

Pumping from a Tank or Sump

How to Clean the Suspended Solids From a Dirty Water Tank

Dirty water in settlement tanks, IBC containers full of dirty water, rainwater harvesting tanks, sumps and other water storage areas from where water is pumped for use can all benefit from an effective self-cleaning filter on the pump suction intake. This will prevent blockages and keep things running smoothly.

The dirty water in your tank can be filtered and pumped out for use elsewhere, while the pump and filter stay clear preventing any downstream equipment from becoming blocked. But…….everything filtered out is still in your tank.

Here’s a neat solution to crud accumulating in storage and settlement tanks. A self-cleaning filter can be used to collect suspended solids in a smaller container than your storage tank. The smaller tank can be purged or pumped out with a solids handling pump as debris accumulates. This is more water efficient than periodically draining a much larger tank.

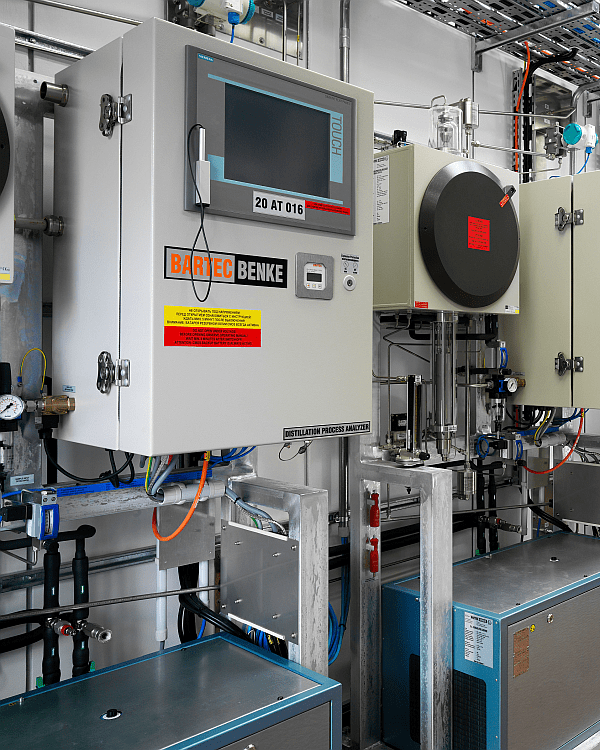

Sampling and Dosing

Water Analysis, Monitoring and Dosing Systems

Rotorflush Filters Ltd have developed an automatic self-cleaning filter system specifically to filter sample water for analytical equipment. Development began in response to a requirement to measure levels of chemicals in white water at paper mills, enabling the output to supply analysers without blocking the cells. Output of the system is from 0 to 2 litres / minute.

The system is now used widely in the UK water industry for screening sample water for continuous wet chemistry analysis – primarily for ammonia, chlorine and phosphate analysis. The self-cleaning filter screens down to 60 microns and allows sampling from a static head in a fast loop system. The output flow is not interrupted and the intake filter self-cleans to prevent blocking.

The system is particularly useful for systems using dosing pumps and where there is a need to continuously monitor water quality. The self-cleaning filter keeps the filter mesh clear to deliver low maintenance sampling and filtration, particularly useful in food manufacturing and processing.

We also supply submersible sample pumps with built-in self-cleaning intakes for use directly in a water supply. Both products are ideal for supplying filtered sample water for to analysers.

Frequently Asked Questions

Rotorflush products allow water contaminated with solids to be screened and pumped while minimising the risk of blinding or blockage. This means that our self-cleaning filtration products can be used for

- Filtering Laundry Water

- Screening White Water

- Filtering Water for Cooling/Heating

- Salad and Vegetable Washing

- Filtering Sample Water for Water Monitoring and Dosing

or any industrial process where particulate needs to be screened out of water for recycling, reuse, or disposal. Our products are often used in purge tanks to remove contaminants so that water can be reused.

All of our self-cleaning intake screens are specified to suit required flow rates.

Filter pumps are recommended based on the flow rate and pressure needed, taking into account any pressure losses through your set-up.

Intake strainers and screens are specified according to the maximum flow through that is required.

Consideration should be given to what mesh size you need - top tip, go for the largest mesh size you can get away with to minimise maintenance.

Yes, environmental regulations may determine the type of filter pump or strainer to be used. Products can be sized to account for Eel Regulations or EPA rule 316(b) if applicable, so that intake velocity and mesh size meet regulatory requirements.

We wish it were possible to screen all types of fluid with our products, but there are limits. Rotorflush products work very well in dirty water or other fluids where the viscosity is the same or very close t that of water. So, no sludge.

Oil and grease in the water will also limit the efficacy of Rotorflush products - grease and oil combine readily with fibrous material and is extremely difficult to screen once it begins to accumulate.

Yes – because our products pump and filter directly from a dirty water source, there is less need for expensive in-line filtration.

All our products have built-in self-cleaning back-washes that prevent intake screens from blocking, keep pumps clear and protect other connected equipment. This reduces maintenance, minimises downtime and can extend the life of pumps. Screening water for reuse can also cut costs.

Case Study

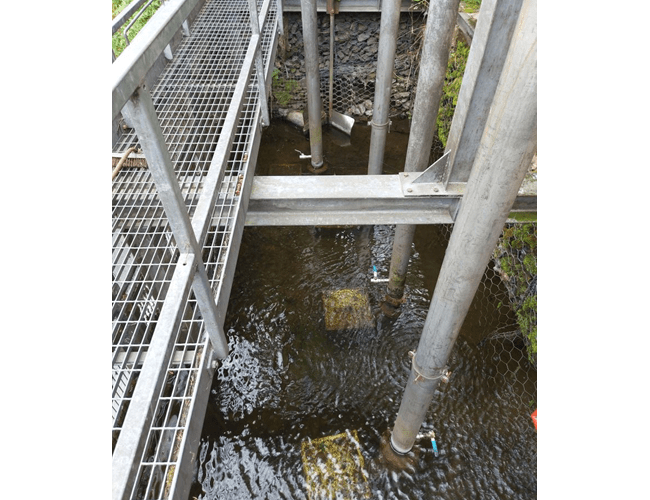

Of the 3 intakes at the Glenfiddich extraction point, the Rotorflush was the only intake that was working and not blocked up.

Naomi Way

Rotorflush Filters LtdThe site had 3 intakes which at the time had traditional basket filters. In addition to this, the filters were preceded by a large screen. Grants told Rotorflush that in the autumn the significant leaf fall required one of their workers to clear the screen of leaves “24/7”.

Talk to an Expert About Your Requirements

Call us now on 01297 560 229 | 8am - 5pm GMT,

or Email sales@rotorflush.com and a member of our expert, friendly team will call you back and find the self-cleaning filter, strainer or filter pump to suit your needs.

- We work with you to identify your issues

- We can design & build a custom solution

- We can deliver our solution worldwide

Arrange a Call Back

This website uses cookies to ensure you get the best experience. Learn more