How Rotorflush Eel Screens Contributed to the Upgrade of Raw Water Intakes for a Major UK Water Company

C J Hiscock

Published

Eel Screening at Water Treatment Works Intakes

What we were told:

A UK Water Company approached Rotorflush filters with their requirement for flow rate and eel screening at three river intake sites. This equipment was a critical part of their ongoing schemes to upgrade and increase the capacity of three raw water intakes treatment works in their area.

Each site required a different flow rate, and each site layout differed in depth and width. All three sites would be gravity fed from river to wet-well and Eel Regulations demanded an intake velocity of no more than 0.1 metres / second through 2 mm mesh.

The three sites required respectively:

- Peak abstraction flow total: 1579 l/s

- Peak abstraction flow: 300 l/s at each of the two intakes

- Peak abstraction flow: 1130 l/s

The intake screens would necessarily be self-cleaning to keep the 2mm screen mesh from blocking.

The initial plan was to replace existing intake structures with a steel wall into which the Rotorflush screens would fit as a penstock. This required working with a third party engineering company to finalise the design of a duckfoot connection and lifting bar for the screens.

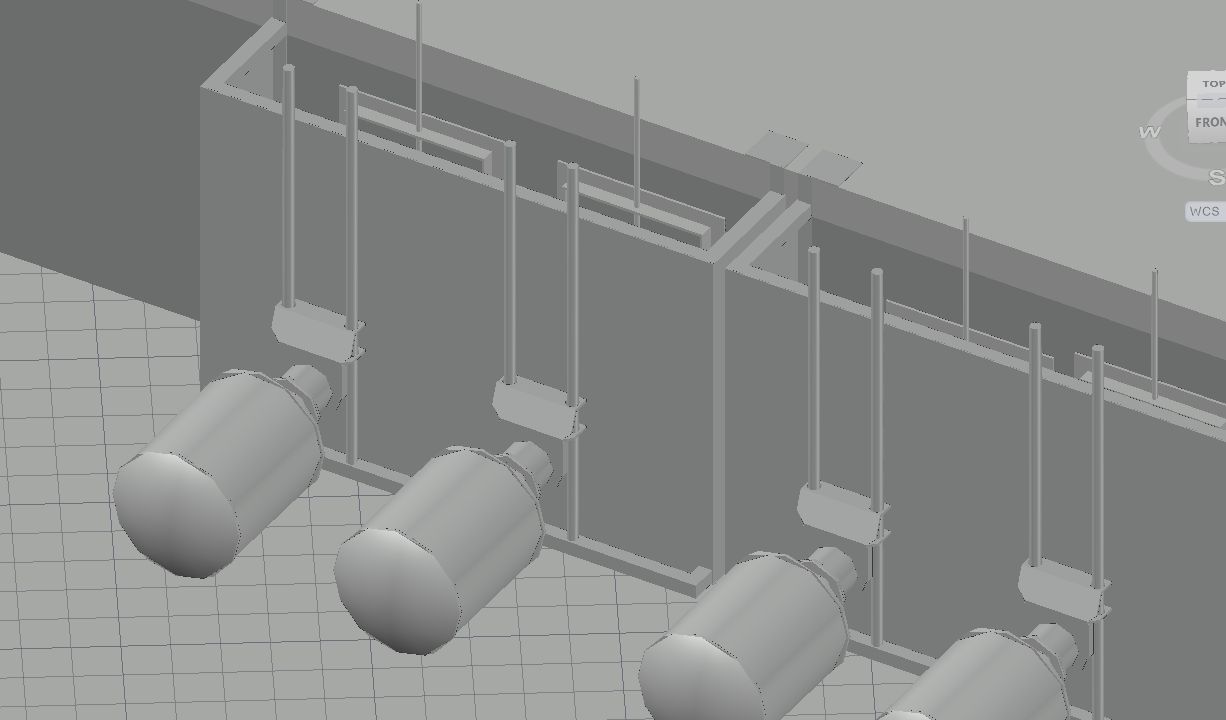

First sketch for intake penstocks and Rotorflush eel screens

What we did:

Rotorflush Filters refined the requirements with the client - then put forward a proposal for the manufacture and supply of multiple gravity fed self-cleaning Eel Screens for each of the three sites. The screens would be manufactured in stainless steel, fitted with outlets to suit each site, and adapted for horizontal placement and lifting on a bespoke guide rail system.

The intakes were to be sized to constrain the intake velocity to meet Eel Regulations and fitted with 2 mm mesh.

The screens required at each site were sized for eel regulations and configured to suit the depth and width constraints of the intakes.

- Site 1 required 7 x RF800-900LW Filters plus a standby - each 950 mm diameter screen capable of delivering an eel friendly 200 litres a second

- Site 2 required 4 x RF600-600LW Filters - each 750 mm diameter screen capable of delivering an eel friendly 100 litres a second

- Site 3 required 7 x RF600-600LW Filters plus a standby - each 750 mm diameter screen capable of delivering an eel friendly 100 litres a second

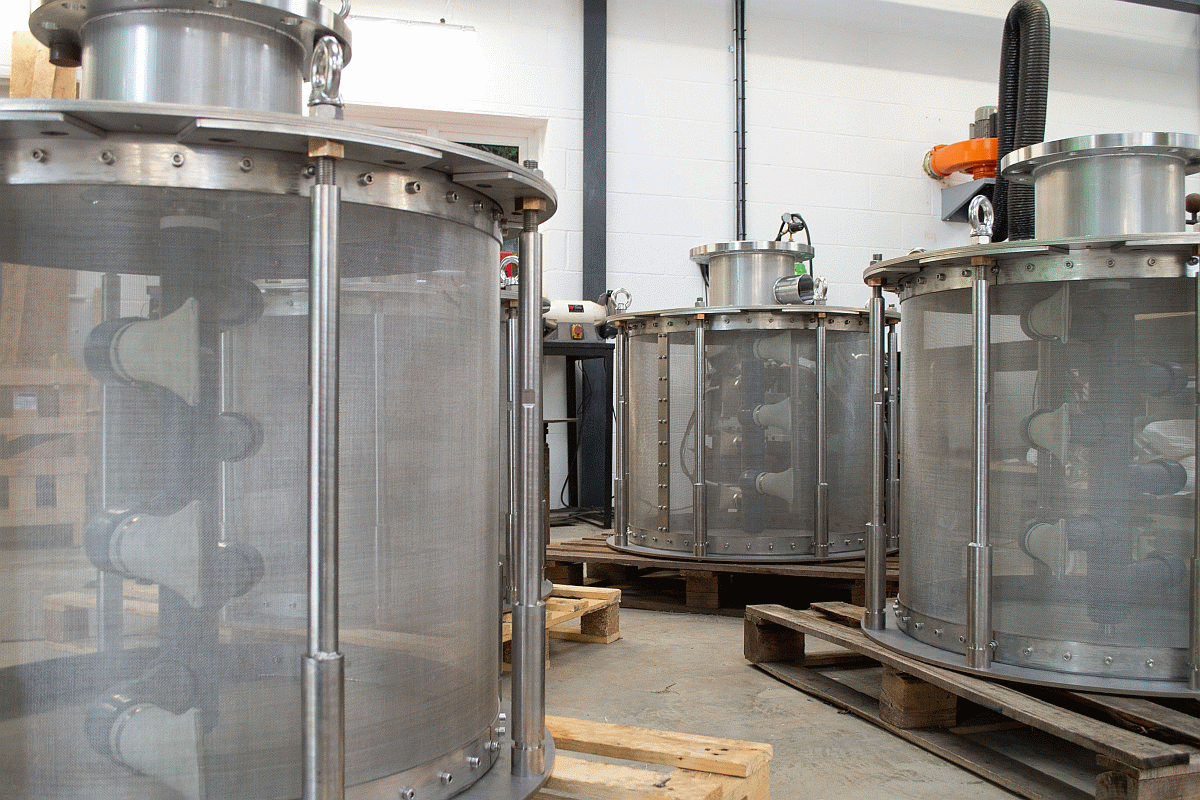

Designs were completed and signed off for each screen, components manufactured and the screens assembled and tested by Rotorflush at their workshops.

RF600LW Screens in production

And we also…..

..adapted the screens for use on a guide rail system. While Rotorflush concentrated on the lifting arrangements, another engineering company devised the angled penstock connections.

Rotorflush was responsible for CFD and FE analysis of the screens as they were being designed and built to ensure that pressure losses were kept to a minimum and that the screens were strong enough to with stand extreme conditions.

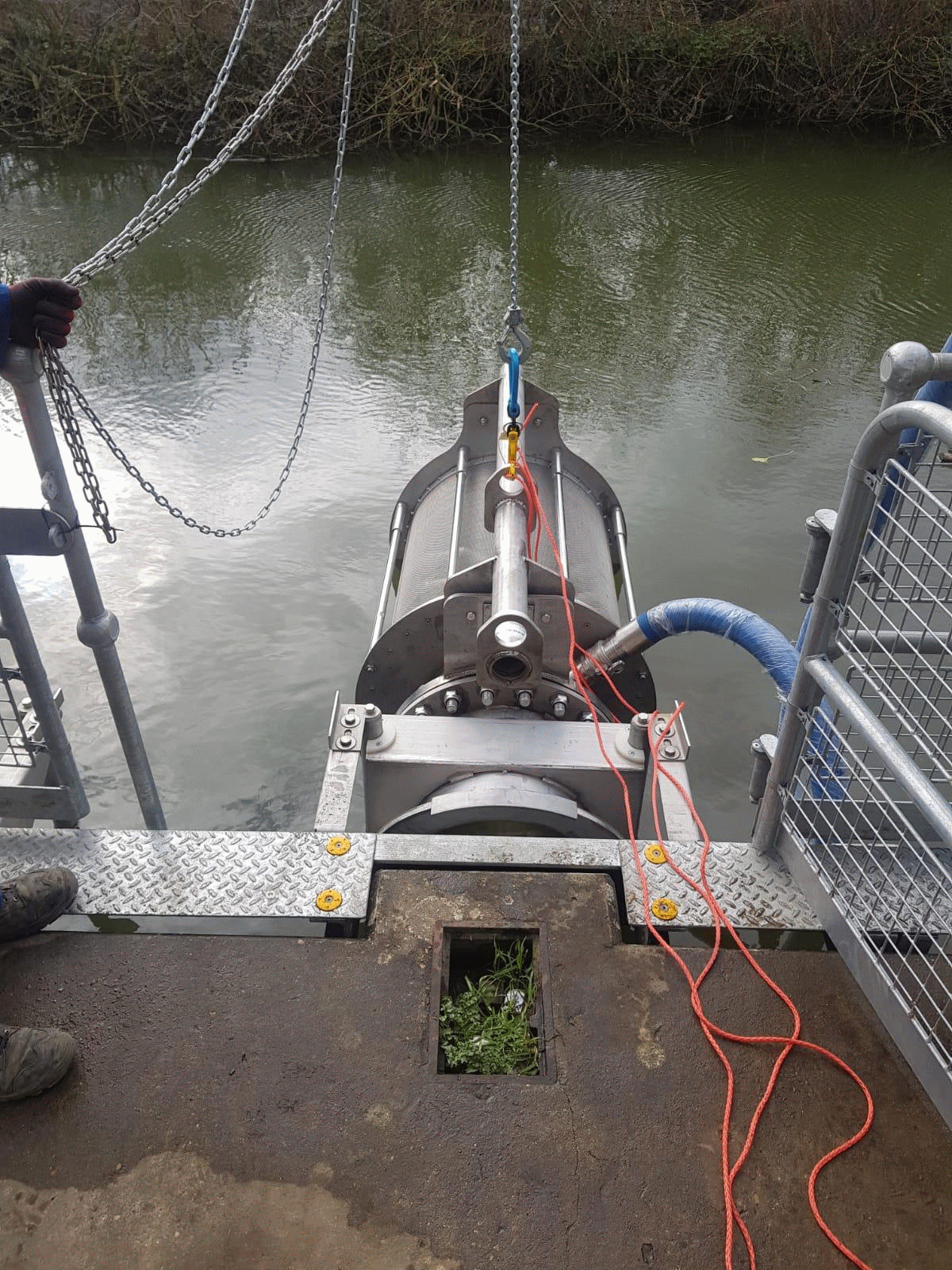

The guide rail system provides for easy lifting for maintenance, and protection from large debris in the river. We estimated that only a very low maintenance schedule would be required – each filter would need a pressure wash at site once every 12 months. The overall design of each intake allows for each filter to be lifted individually as required, meaning maintenance does not interrupt the intake operation.

RF600LW being lowered and raised

And the outcome was

All the screens were delivered on time to each site ready for installation. The screens were all installed and commissioned, providing easily maintainable eel screening at all three raw water intakes.

Self-cleaning Eel Screens in situ

Explore more topics

Ready to brush up on something new? We've got more to read right this way.Share this insight

-

Increase productivity

-

Reduce maintenance

-

Filter to your requirements

Contact our friendly experts now

to discuss your project

Or call our team on:

01297 560229

Find out more....

...... about how to meet your eel screening requirements using Rotorflush self-cleaning filters, intake screens and filter pumps.

This website uses cookies to ensure you get the best experience. Learn more