Submersible Sample Pump Self-cleaning Intake Filter Supplies Analysers without Blocking.

C J Hiscock

Published

Submersible Sample Pump with Self-cleaning Intake Filter Supplies Analysers without Blocking

Sampling pumps and environmental monitoring equipment can easily block. Therefore, they often require frequent maintenance where water conditions are less than ideal. At different times of the year, algae blooms and weed growth can overwhelm operations. Suspended solids, silt and debris can present challenges to equipment in remote or unmanned sampling sites. Downtime and maintenance are reduced as a result when a submersible sample pump with self-cleaning intake filter supplies analysers without blocking.

More stringent environmental legislation requires water utilities, factories and anyone discharging water into the environment to continuously monitor outfalls.

Ammonia Molecule

Often getting a continuous sample of water to the analyser is a problem. The final effluent from a waste-water treatment works must be analysed. Monitoring concentrations of ammonia is a typical example. Although final effluent is relatively clean, it still contains particles that can block analysers. The effluent is also a very good medium for algae growth that can easily block filters and analyzer tubing.

- Readability

The methods used to address these problems have met with varying degrees of success. The most common, which is also the highest maintenance, is a Y strainer. These often need cleaning several times a day. This is both expensive and on many sites impractical. Other solutions use compressed air to clean filters automatically. These and other types of filter interrupt the flow to equipment and often add additional complexity to installations.

These approaches do not address the root causes of blocking and plugging. So either the sample pump and strainer gets clogged or the pump and strainer allow debris into the analyser. An effective self-cleaning filter on the sample intake will avoid these issues.

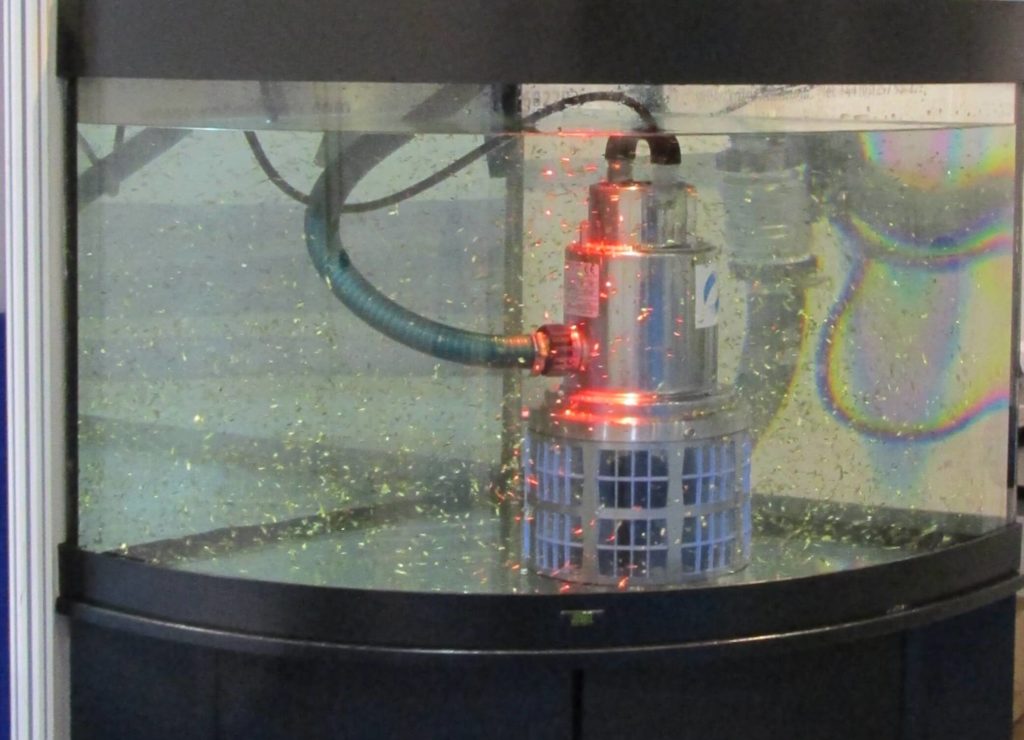

Rotorflush Submersible Sampling Pumps

Rotorflush submersible filterpumps™ have a built-in self-cleaning inlet filter. An additional impeller inside the pump intake drives the self-cleaning filter mechanism. This self-cleaning mechanism runs continuously while the filter pump is working. Debris, weed and suspended solids larger than the filter mesh apertures are gently but firmly cleared from the filter, preventing clogging and blockage. Normally we fit 115 micron (140 mesh) for supplying analysers, but we can also fit 60, 300 and 1000 micron aperture mesh as required.

The self-cleaning screen stops the filter pump from blocking and supplies a filtered sample to the analyser. This one unit replaces the need for screens, pumps (with blocked strainers), and inline filtration ahead of analysers providing a continuously filtered supply to the analyser. Maintenance is down, peace of mind is up, and running costs are lower. That’s how a submersible sample pump self-cleaning intake filter supplies analysers without blocking.

We now have hundreds of these pumps working at sewage works across the UK, increasing analyser reliability and driving down costs. We also have US specification pumps with 115 volts 60 Hz motors for our customers in America.

Stay ahead of the curve

Join our mailing list to get access to:

- Industry news

- The latest products

- Tips to improve your filtering system

Explore more topics

Ready to brush up on something new? We've got more to read right this way.- Fish

- News

- Analyser Filters

- Rotorflush

- Article

- Filterpumps

- Eel Screening

- Waste Water Treatment

- Water Source Heat Pump Filtration

- Agriculture

- Industrial Process Water

- Raw Water Intake

- Water Industry

- Cooling Water

- EPA Rule 316(b)

- Hydroponics

- Recycling

- Liquid Solids Separation

- How does it work

- Golf

- Environment

Share this insight

-

Increase productivity

-

Reduce maintenance

-

Filter to your requirements

Contact our friendly experts now

to discuss your project

Or call our team on:

01297 560229

This website uses cookies to ensure you get the best experience. Learn more