Rotorflush Products for Environmental Improvement

How Rotorflush Filters Ltd's products or service improves natural environments previously damaged by degradation (e.g. reforestation; endangered species repopulation)

Christofero Centenario

Published

Rotorflush Filters Ltd manufacture and supply unique ranges of industrial self-cleaning water filtration products.

Rotorflush filtration products are for use in screening water that may be contaminated with particulate, suspended solids, weeds, leaves or material introduced by agricultural or industrial processes.

The self—cleaning suction intakes allow water to be pumped or moved by gravity through filter mesh as fine as 50 microns without blocking.

This means that water used for cooling systems, heat exchange, wash water and other applications where equipment has a low tolerance of debris, can be pumped without repeated downtime and interruption.

These products enable water source heat pump systems and cooling water systems to use raw water for sustainable energy solutions.

They also enable re-use of water across a range of industrial and agricultural applications, removing debris and particulate that would otherwise preclude water recycling.

By providing effective filtration and screening of water, Rotorflush self-cleaning intake screens and filterpumps make the re-use of process water feasible and cost-effective.

This is in keeping with Rotorflush Filters Ltd’s commitment to:

All kinds of Rotorflush self-cleaning filtration products

The world is gradually moving away from the use of fossil fuels towards more sustainable sources of energy, harnessing the power of renewable natural resources for power and heat. Accessing the latent energy in bodies of water through the use of heat pump systems becomes possible if heat exchange equipment can make effective use of the water.

Often this is only possible if the water to be used can be efficiently screened to protect the heat exchange systems. Rotorflush self-cleaning intakes enable the energy stored in lakes rivers and other water bodies to be used as a renewable energy resource.

Filterpump installation under a bridge to screen intake water for a water source heat pump system

Heat pump systems are an efficient way of transferring heat from, air, the ground or water to provide heating. Water source heat pump systems are particularly efficient for larger scale (often commercial or district wide) heating systems and better in cooler climates where air temperatures can fall considerably lower than the ambient temperature of water bodies.

Water source heat pump systems take in water and extract the heat retained in it through heat exchangers. To achieve this efficiently and with minimal maintenance, raw water (from lakes, rivers, ponds or the sea) must be screened to prevent the narrow apertures in heat exchangers from getting blocked.

Rotorflush self-cleaning intake screens are a vital component in water source heat pump systems. They require no additional power source, their operation is powered by water, and although their mesh is fine – typically 1 mm or 2 mm, their ability to self-clean prevents the screen from blinding and protects the other heat pump system components from damage.

Examples:

Heat pump system detail - complex water source systems need well screened water

Many industrial operations generate heat, and some processes require active cooling. Heat recovery through cooling water enables some of the energy that may otherwise be lost to be re-cycled.

A typical example is a data centre; their operation generates a considerable amount of heat and the equipment needs cooling. Water cooling is often the most cost-effective method.

Cooling system water needs to be screened to protect heat exchange equipment. The cooling water in turn can be used to transfer the heat it has gained heat to other applications where it is needed, effectively re-using the energy lost through heat in the data centre. Heat generated by the data centre can be used in heating systems nearby.

Examples:

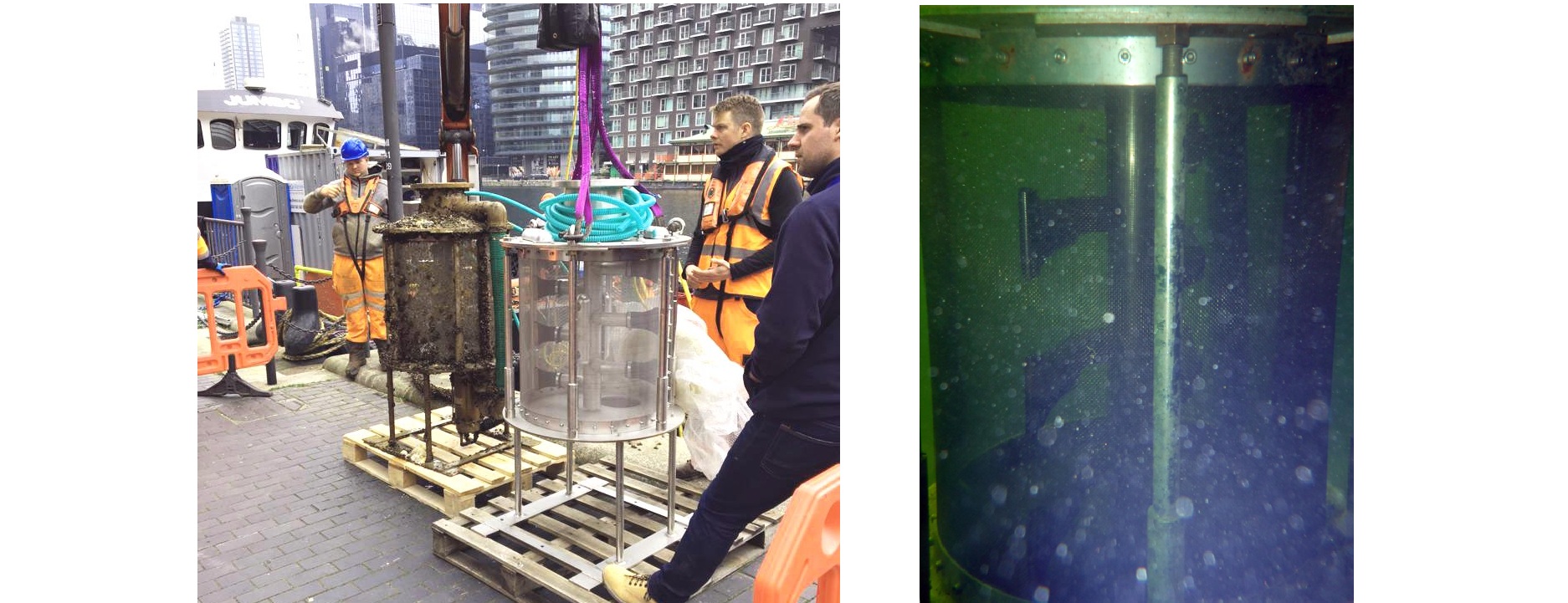

Docklands intake screens - one in one out and view from underwater

Demand for water is rising. Ensuring reliable supplies of clean potable water is costly. Conserving available water supplies and re-using water is becoming less optional and increasingly the norm.

Good water filtration – that is fine enough to enable the re-cycling of used water is a critical component of rainwater harvesting, grey water systems, and a raft of water recycling set-ups across many industries. Good filtration allows water to be screened finely while ensuring that the filter mesh does not block. This minimises downtime (and cost) while enabling effective screening and water re-use. This is what Rotorflush self-cleaning filtration products do.

Waste Water Treatment works use a lot of water. Primary waste water treatment requires raw sewage to be screened, typically to 6 mm, ahead of further treatment processes.

Sewage works intake screens capture trash and larger solids on band screens. Debris trapped on the screens is cleared off the screens by powerful jets of water. The narrow jets of spray bars easily block so using raw sewage as a source of wash water has proved difficult. Using clean potable water is wasteful and expensive.

Rotorflush self-cleaning filtration products allow secondary effluent to be used for wash water without the spray bar jets blocking and hugely reduce the use of clean water for wash water.

Examples:

Rotorflush filterpumps - pumps with an integral self-cleaning intake - providing washwater at a Waste Water Treatment site

Water is a scarce and increasingly costly resource in ever greater demand. Re-cycling and re-using water where possible both conserves a precious resource and saves money.

Drinking water is costly and there are usually constraints on the use of raw water. Some activities, for example salad and vegetable washing use huge amounts of water; washing equipment is easily blocked by organic material, plant debris, earth and other detritus. Rotorflush self-cleaning water filters give vegetable washing systems the ability to screen wash water so that it can be re-used many times over. This greatly reduces the amount of source water used operationally, saving water and money.

Rotorflush self-cleaning water filters and strainers have enabled industries as diverse as stone cutting and industrial laundries to recycle water by removing particulate and allowing used water to be re-used. Rotorflush filters can remove particulate down to 50 microns without interrupting the water supply need for these applications.

Examples:

Farm produce washing equipment re-uses its water filtered by a Rotorflush strainer

Making the best use of water, a scarce resource, by enabling its use as a source of renewable energy is feasible and cost-effective if the systems designed to do this have effective, self-cleaning, low maintenance, wild-life friendly water screening in place. Rotorflush Filters Ltd’s unique self-cleaning intake screens and filterpumps provide the means to do this.

Clean water is often contaminated through its use in industrial and agricultural processes. By providing the means to screen out debris practically and cost effectively, Rotorflush Filters Ltd’s unique self-cleaning intake screens and filterpumps make water recycling and re-use possible in many sectors and applications.

This conserves water, and makes best use of a key resource.

Rotorflush Filters Ltd cares for the environment

Share this insight

Contact our friendly experts now

to discuss your project

Or call our team on:

01297 560229

Related articles

View all

How Rotorflush Filters Ltd's products or service improves natural environments previously damaged by degradation (e.g. reforestation; endangered species repopulation)

How to stop fish and eel screens from clogging and blocking. How to reduce intake screen maintenance costs.

Complying with the Eel Regulations – Our Self-cleaning filters are eel and fish friendly, ensuring low maintenance, easy to install, EPA and EA regulation compliant screening of the water you need.

This website uses cookies to ensure you get the best experience. Learn more