Self-cleaning Filters for Analysers

Self-cleaning analyser filter system for sample water supplied to online wet chemistry analytical instruments, water monitoring equipment and dosing systems. Low maintenance sampling and monitoring.

Naomi Way

Published

Wet chemistry water analysis has always struggled with quality of sample water. On-line analytical equipment for water monitoring and dosing systems have low tolerances for particulate and debris.

Previously, and for many applications, intermittent sampling and measuring, allowing a ‘rinse’ between cycles mitigated the possibility of blockages and damage to sensitive instruments. Now, however, system tolerances are smaller and more stringent regulatory regimes demand continuous rather than discrete measurement and monitoring.

This article looks at two methods of pre-screening sample water to allow on-line analysers, dosing systems and other water monitoring equipment to operate continuously and avoid blockage or damage from particulate and debris in sample water.

Water analysis relies on precise measurements and consistent flow rates to ensure accurate results. Interrupted sample water supply can disrupt these measurements and compromise the integrity of the data collected. Worse still, any blockages in the sampling system can lead to equipment damage.

A well set-up system for analysing water will already have several means of protection and of identifying potential issues before they occur. For example:

Of these, by far the most effective means of avoiding difficulties and interruptions to continuous on-line water analysers and dosing systems is filtration.

Continuous water analysis implies a continuous supply of sampled water. The requirement to analyse and monitor water quality spans many industrial sectors, and the source of sample water can be as diverse as the industries themselves

Take food processing as an example. For instance, garlic bulbs need to be washed and processed before hitting the supermarkets, and disinfected for human consumption. The sample water supplied to the analyser and dosing equipment determining the degree of disinfection is muddy, gritty, full of garlic skin and other organic debris.

The sample water needs to be finely filtered before being processed. Not much water at all is required, but the flow needs to be continuous.

Another example from the water industry. Water from rivers is fed into water treatment works to be brought up to drinking water standard. Water is sampled on intake, and the quality of water can vary widely. Extreme weather events can churn up debris in the river, or there may be a surfeit of weed or algae. The water needs to filtered ahead of analytical instruments, particularly as many sample sites are remote or unmanned.

There is a danger of course that by pre-filtering or screening sample water to prevent blockage to analysers, all that happens is that the blockage is moved back a stage to the filter. This is better in that filters tend to be less expensive to replace or maintain than analysers and dosing systems, but does not avoid the issue of disruption to continuous monitoring.

This problem can be greatly reduced by the use of either of these two innovative sample filtration products:

Submersible Sample Pump with Built-in Self-cleaning Filtration.

Rotorflush Filters Ltd's smaller submersible pumps, Omnia, Flint and Idrogo Filterpumps™, are used widely in the water industry and beyond for raw and dirty water sampling for analysis. These are submersible centrifugal pumps with integral self-cleaning suction intakes that can screen and pump water simultaneously. Water is filtered as it is pumped, while the innovative self-cleaning intake prevents the filter mesh from blinding.

These pumps are preferred for raising sample water because they can screen down to 60 microns without blocking. Because water is filtered as it is pumped from source, analytical equipment is protected against clogging and blocking by any debris or particulate that may be in the sample water.

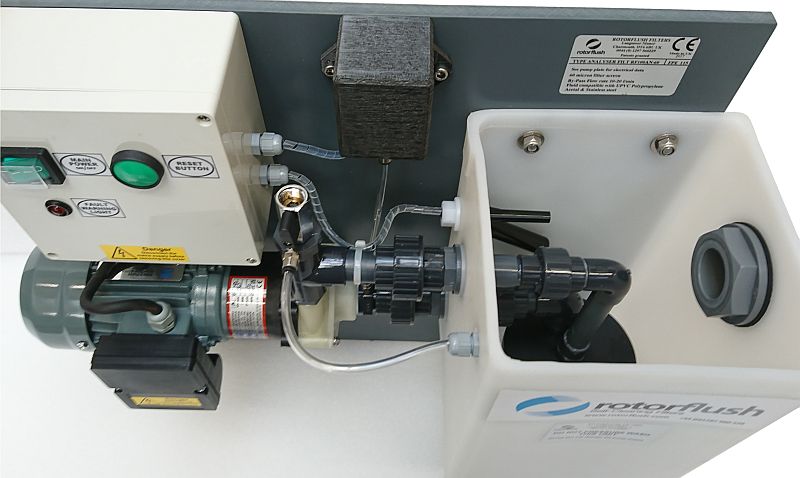

Purpose Built Self-cleaning Filter System for On-line Analysers

Rotorflush Filters lLtd's RF100ANQ Self-cleaning Filters for Analysers are specifically developed for water monitoring equipment and analysers. The output flow runs continuously, and the self-cleaning filter has a continuous backwash to prevent blocking. The system screens dirty water as it pumps sample water to analytical equipment.

It is excellent for filtering difficult samples contaminated with suspended solids for supply to chlorine, ammonia and other analysers.

Designed to work as a wall mounted fast loop system, sampling is from a static head. The small pump in the system delivers the screened sample water to your analyser and drives the self-cleaning filter backwash to prevent the filter mesh, pump and analyser from blocking and blinding.

Share this insight

Contact our friendly experts now

to discuss your project

Or call our team on:

01297 560229

Related articles

View all

Self-cleaning analyser filter system for sample water supplied to online wet chemistry analytical instruments, water monitoring equipment and dosing systems. Low maintenance sampling and monitoring.

This website uses cookies to ensure you get the best experience. Learn more